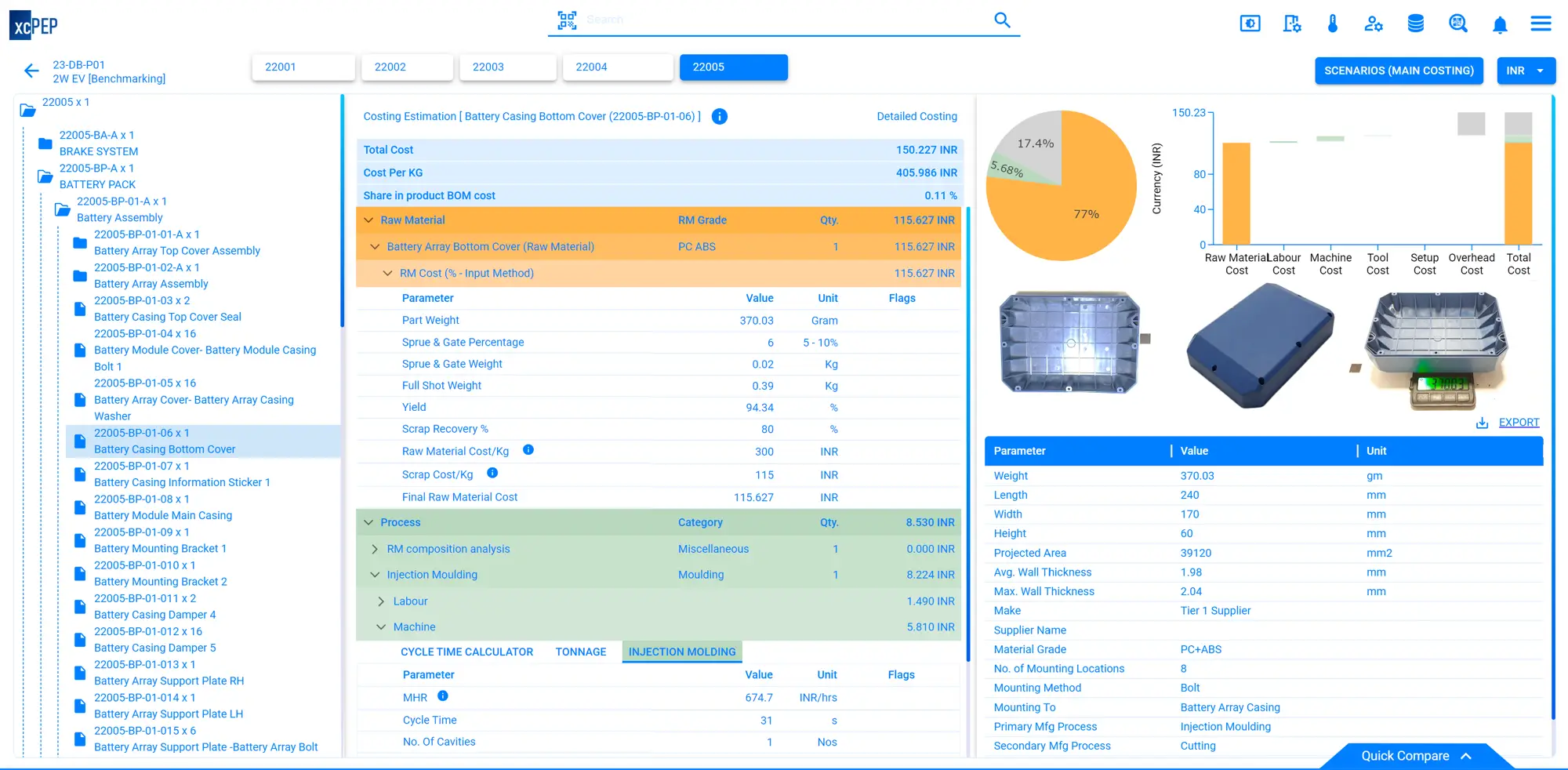

Should Costing backed by xcPEP

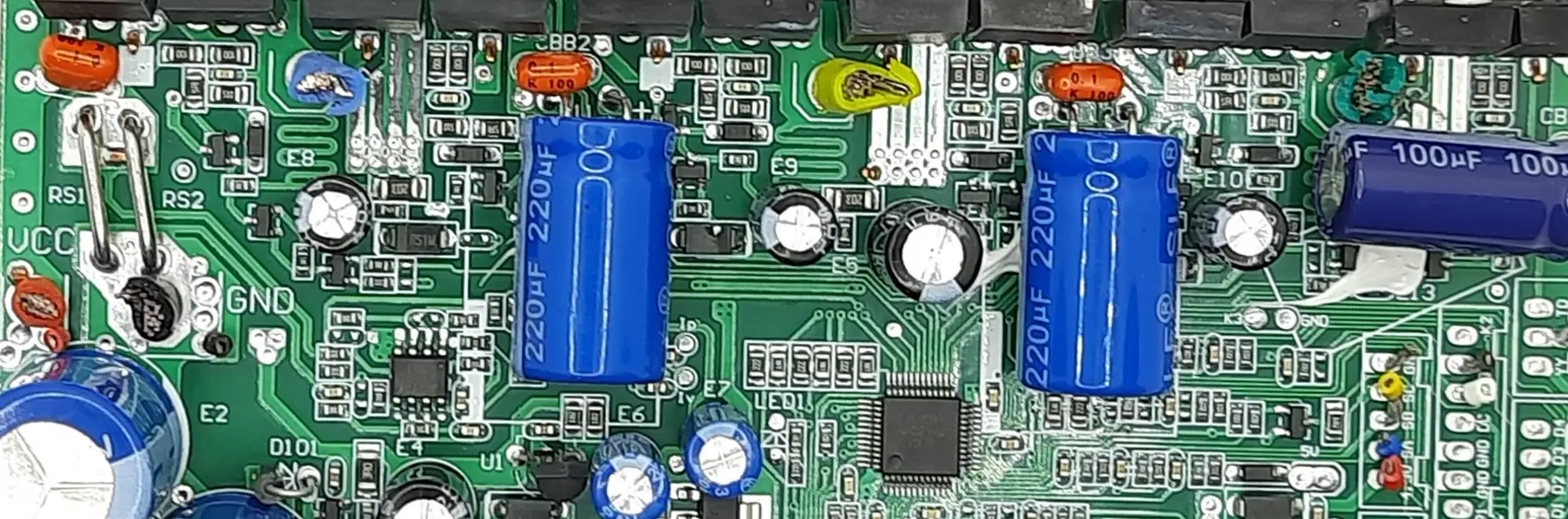

Should Costing is a strategic cost management approach where costs are analyzed and justified from a "should base" without considering historical expenditures. Should Cost of a manufactured product consists of item wise detailed cost of raw material, manufacturing process, tooling and overheads.

This method ensures that each cost incurs scrutiny and must be justified without referring to previous spend. This rigorous analysis empowers organizations to identify and eliminate unnecessary expenses, optimize resource allocation, and set precise target costs for products and services.

Excel fails at scale in Should Costing

Excel has several limitations when used for conducting organization wide should costing of thousands of parts from hundreds of suppliers from dozens of different geographies. Below are the some of the challenges in using Excel for should costing.

CAD based costing tools fail in detail

Such software is generally designed for providing a rough should cost estimation to designers while they are designing a part. These estimates lack the granularity, depth, accuracy and dependability required by cost engineering and procurement teams while negotiating with different stakeholders. xcPEP is built from scratch for cost engineering and procurement teams.

How Advanced Structures India's Should Costing service helps?

Engagement Models for Should Costing Services

Costing Projects

Suitable for smaller organizations or short term requirements

You can engage with us for specific projects, allowing you to benefit from our should costing competence as needed.

- Continue to use xcPEP and run scenarios even after the project.

- Collaborate with colleagues

- Run your own cost reduction exercises

Managed Costing Service

Cost effective solution for larger organizations with sustained requirement

For a more comprehensive solution, we offer annual fixed contract-based services, taking on the should costing function for your organization. This managed service ensures ongoing cost control and optimization.

- Dedicated team for your organization.

- More precise mapping of your locations and norms.

- Ramp up and down as per requirement.

Our Role in Should Costing

Digitization and Automation

At Advanced Structures India, we work with you to perform should costing on your products and competitor's products. Our approach is rooted in first principles and publicly available information, and we focus on bringing speed and efficiency to the table. While we collaborate with leading database companies to buy relevant datasets, we are not a database company and we do not sell any datasets.