Activity based should costing of in-plant activities

As a natural progression to our direct material cost related should costing solution, we also map our customer's in-house conversion activities happening at various plants and lines.

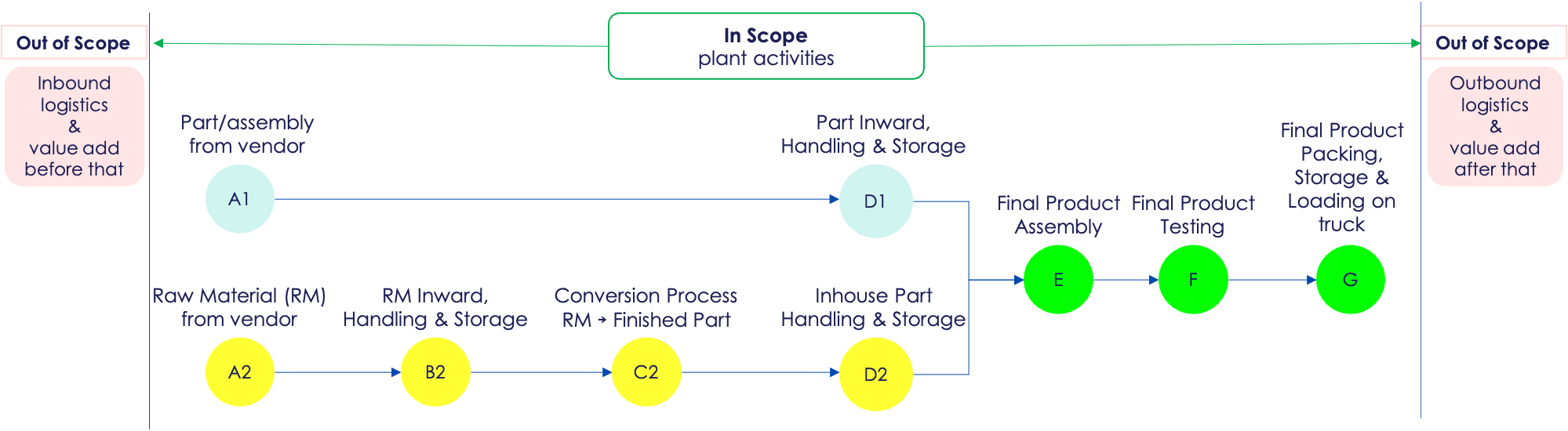

For this we map the flow of cost into -

Following schematic gives and idea of how entire value add and its activity wise cost is mapped by Advanced Structures India using our xcPEP should costing platform.

Cost driver mapping of assembly process

All input costs including machine, labour, power, space, interest etc are mapped by our team in your plant. This is then used to make a precise model of your manufacturing capability and a should cost of every conversion activity and corresponding cost drivers is mapped.

And then we do a should costing of every manufacturing activity

xcPEP has both direct and indirect cost's should costing capabilities. Just like our BOM and part data mapping, we can also map immense amount of data from your plant in a relatively shorter period of time. This allows us to do a highly detailed should costing of every activity in your own plant.

Studies of such scale, detail and accuracy are not possible by your own team or your consultants due to the limit of data mapping and analysis in excel or access based software. xcPEP is designed from scratch for this scale.