DJI Inspire 1 Drone Teardown and Costing

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publishing.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

Explore xcPROC →

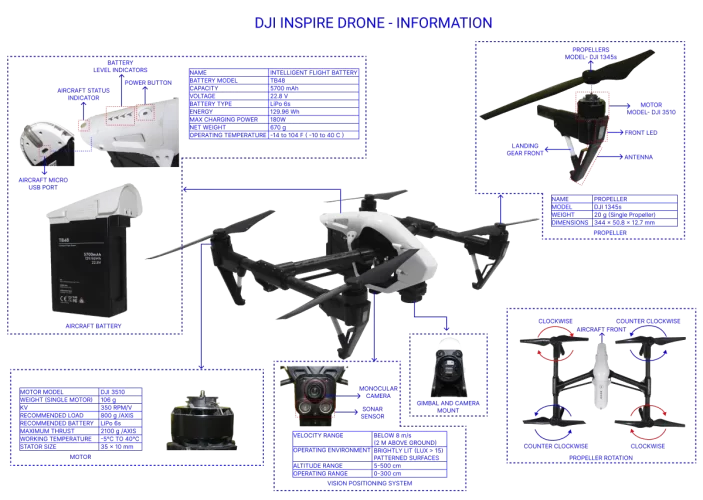

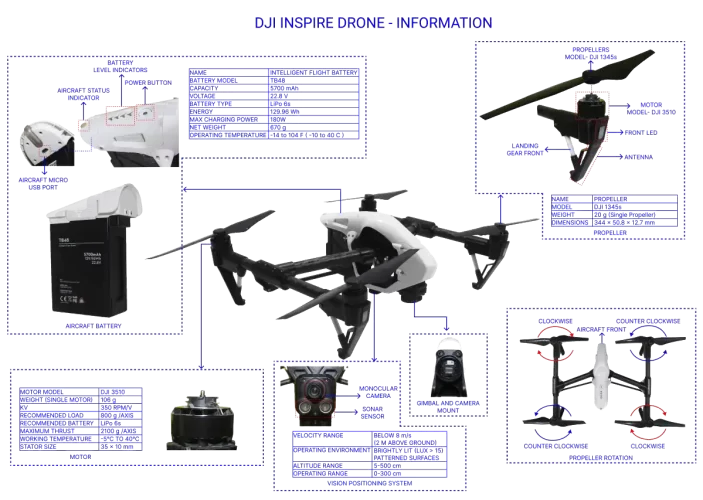

Prominent Features of DJI Inspire 1 Drone

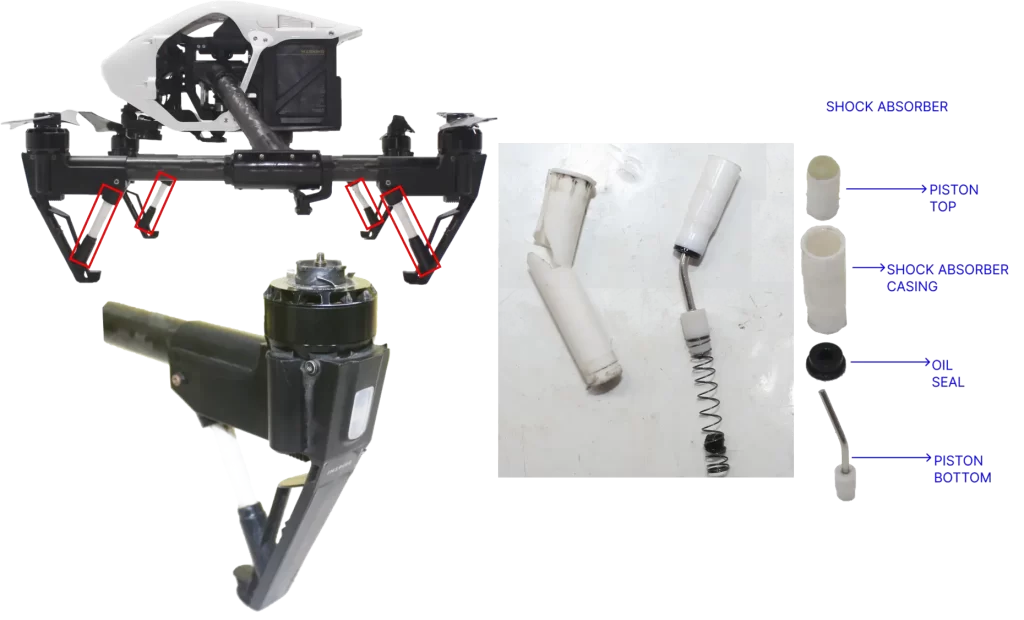

Shock Absorber

4 shock absorbers are provided (one for each leg), which consist of a damper (piston) and a spring. This system is used to absorb the force transmitted to the legs of the drone when landing the DJI Inspire drone. The shock absorber unit consists of:

- Piston

- Spring

- Rubber Seal

- Oil

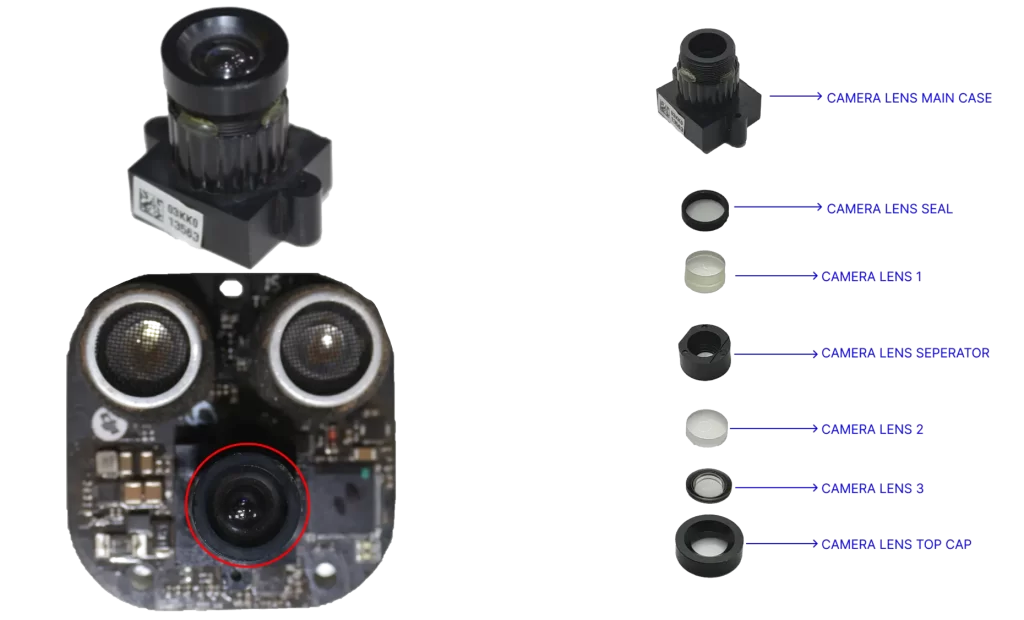

Monocular Camera

The vision positioning system in DJI Inspire drone is provided with a monocular camera and two SONAR sensors which assist the DJI Inspire drone when it is being used indoors.

A monocular camera system consists of 3 lenses, where the bottom-most lens is the fisheye lens for wide-angle view and the other two lenses are used as relay lenses to project the image onto the eyepiece from the fish eye lens (bottom-most lens) and to invert the image, making it erect.

The working altitude range of the Vision positioning system provided in the DJI Inspire drone is 5-500 cm and it works best when operating on non-absorbing surfaces or surfaces with a clear and distinct pattern.

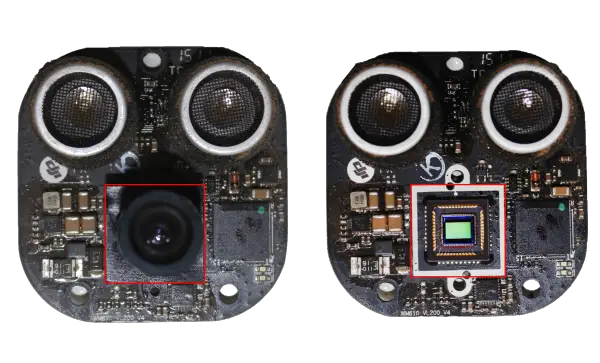

Monocular Camera Sensor

The monocular camera sensor is provided on the PCB in the Vision Positioning System unit.

A CMOS (Complementary metal-oxide-semiconductor) type sensor is provided for image sensing in a monocular camera, these types of sensors are used as they consume 100 times less power than that of CCD (Charge - Coupled Device) and low light sensitivity.

GPS Antenna

A ceramic type of antenna is provided for this purpose as it is smaller in size and more resistant to environmental noise.

GPS is provided in DJI Inspire drone to monitor the current location of the vehicle and communicate with the remote controller.

RTH (Return to Home)

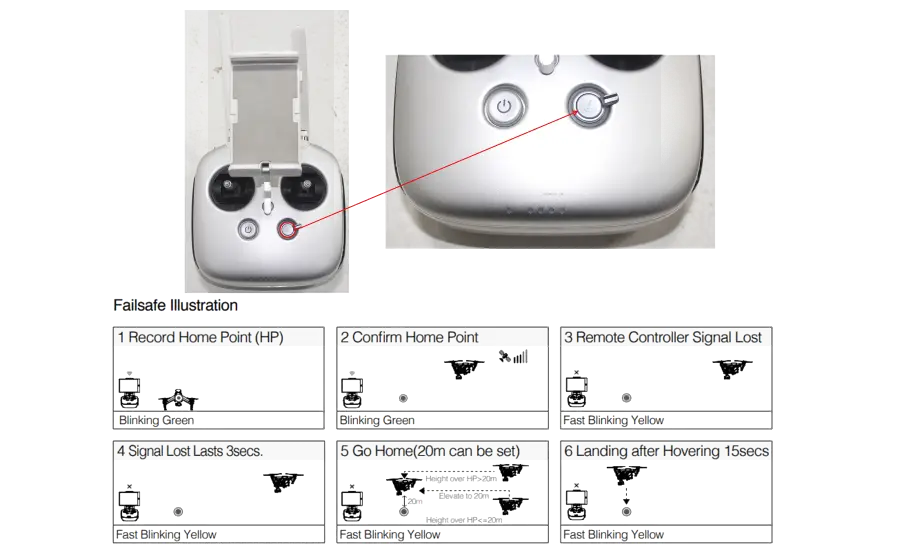

DJI Inspire drone is provided with a feature that allows the drone to return to the home point (previously set by the user) or to the current location of the remote controller. Below are the three cases for RTH functionality to be activated.

Three types of RTH have been provided:

- Smart RTH– This can be activated using a remote controller or DJI GO APP, this feature is user dependent, and this mode can be activated using the controller.

- Low Battery RTH– When the battery reaches a critical level DJI Inspire drone is made to land automatically. This feature is triggered when the battery level reaches below a certain point that may affect its landing.

- Failsafe RTH- DJI Inspire drone returns to the previously set home point when the signal is lost with the remote controller for more than 3 seconds, provided the compass is working.

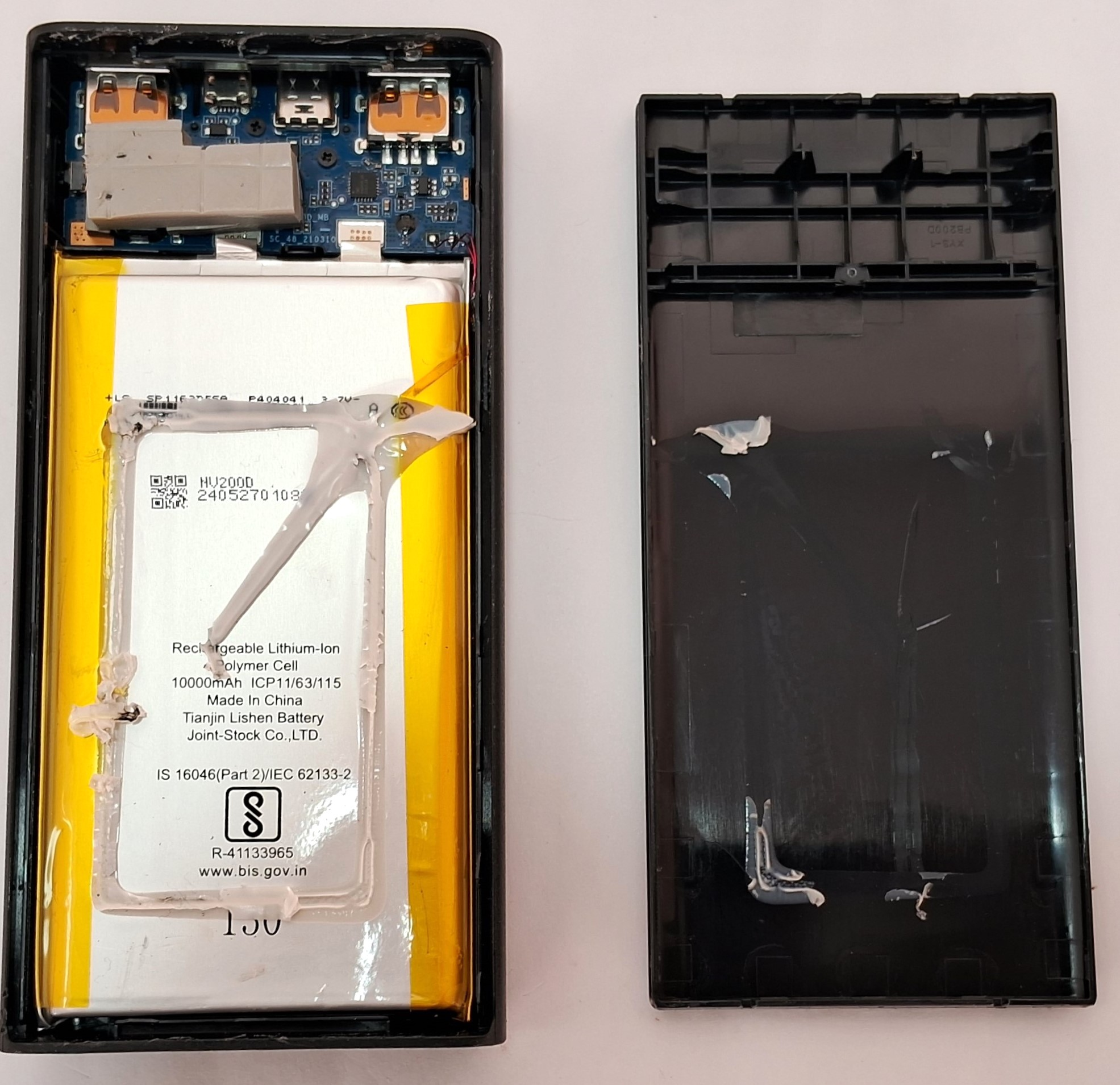

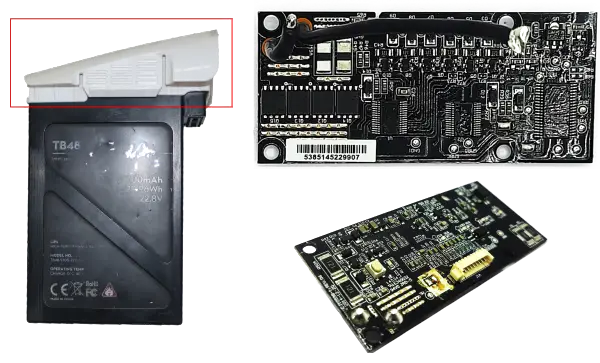

Intelligent Flight Battery System

DJI Intelligent Flight Battery System is provided in DJI Inspire drone where the Battery management system unit is integrated within the battery (BMS PCB is provided on top of the battery).

The maximum flight time using the standard battery is 18 minutes.

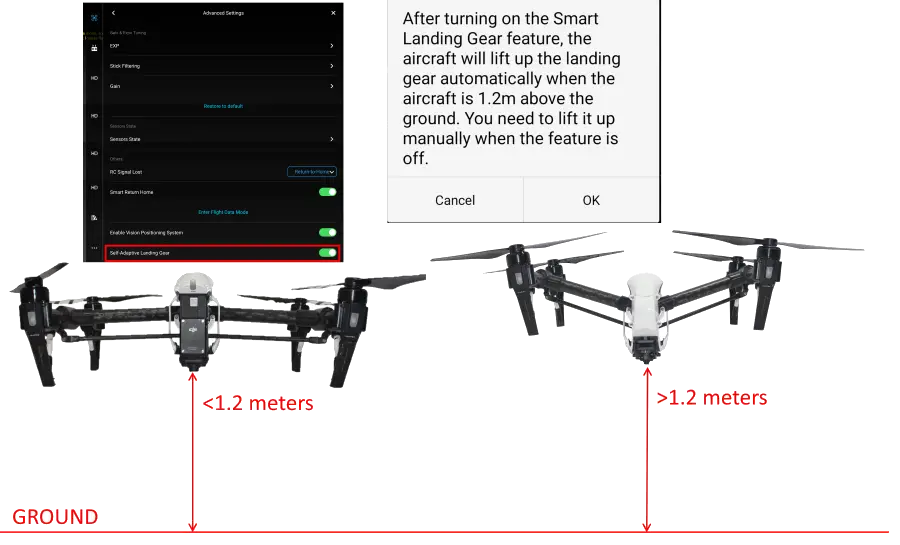

Self-Adaptive Landing Gear

This feature allows the landing gear to lift automatically when the DJI Inspire drone is 1.2meters from the ground surface.

This feature can be enabled using DJI GO App, it is present under main controller settings.

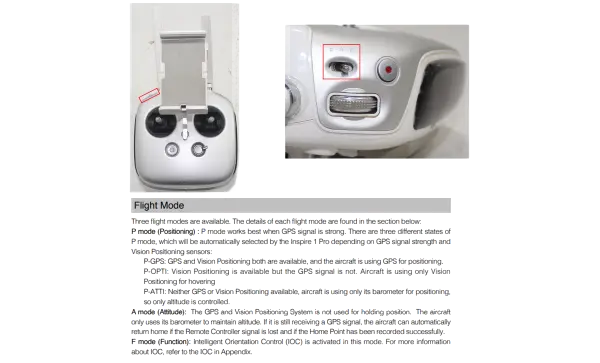

Flight Modes

Three flight modes are provided in the DJI Inspire drone which are:

- P-Mode (Positioning Mode): This mode works best when the GPS signal is strong, three modes are present in P-Mode which will be selected automatically by the DJI Inspire drone.

- A-Mode (Altitude Mode): In this mode, only a barometer is used for maintaining altitude. Both GPS and Vision Positioning Systems are not activated in this mode.

- F-Mode (Function Mode): IOC (Intelligent Orientation Control) mode is activated in this mode. This mode is mostly used for taking photos where the direction of the nose of the drone is not necessarily considered the forward direction of the drone.

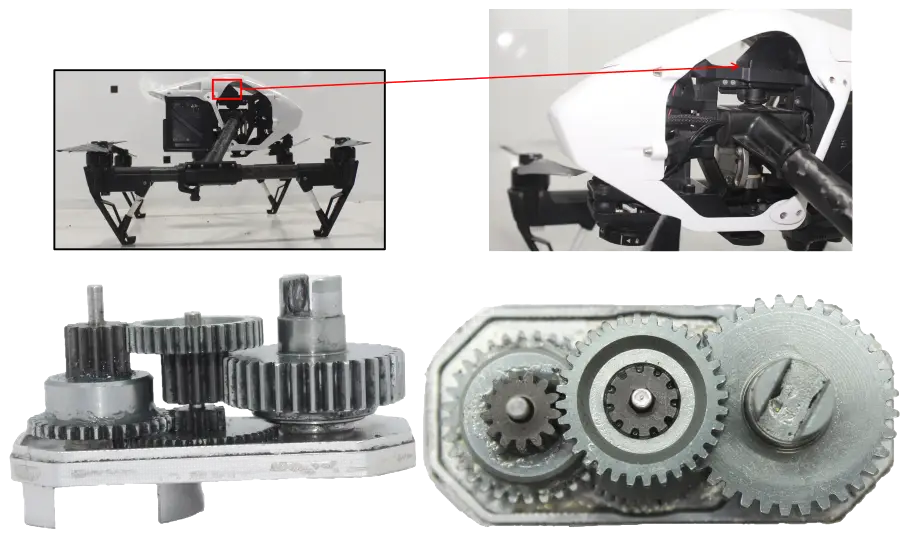

Servo Motor

Servo motor is used for the motion of boom when DJI Inspire drone is switched between different modes.

Servo motor is used as a linear or rotatory actuator, here the motor meshes with a rack and pinion gear for linear motion of boom.

Gear reduction is used inside the servo motor for increasing the torque.

4 gears are provided in the Servo motor out of which two are used for gear reduction.

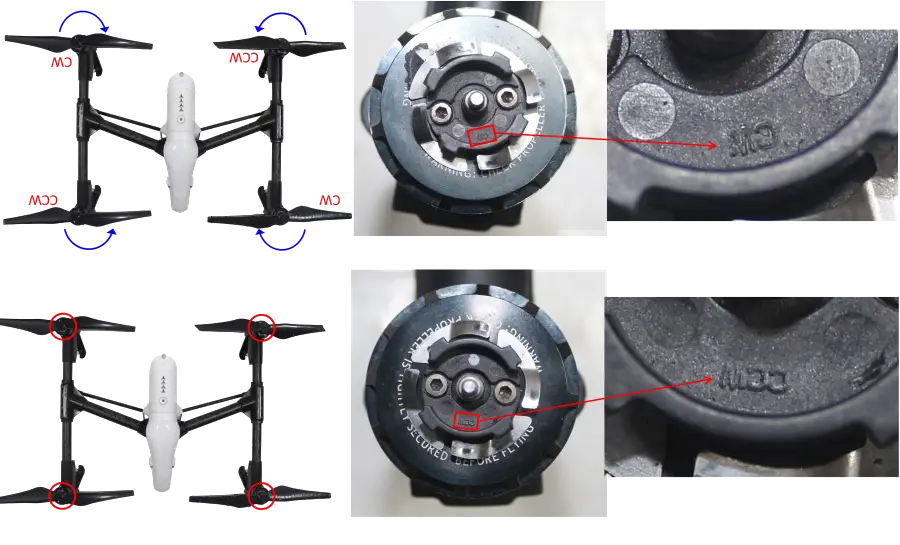

Propeller Direction

The Propeller blades are made to rotate in a specific direction to balance DJI Inspire drone when it is in flight.

Two diagonal blades are made to rotate in the same direction (2 blades will rotate Clockwise and the other ones in Counter clockwise direction to keep the drone stable)

The directions are specified on the motor casing (Propeller Mounting Base).

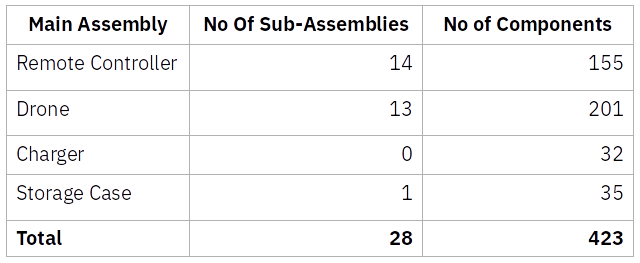

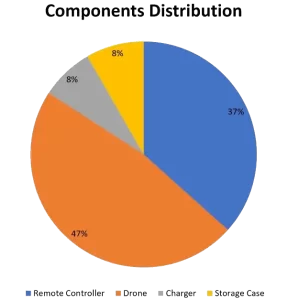

Generation of Bill of Material of DJI Inspire-1 Drone

We have conducted a last-level teardown on the DJI Inspire drone and the following are some outcomes of the study. In the BOM study data relating to various part-attributes are mapped. This data is analyzed for a detailed understanding of the entire DJI Inspire Drone system.

Here we used a Multi-level BOM structure which gives greater details on the assemblies and their child parts in the DJI Inspire Drone.

The BOM structure for the DJI Inspire Drone, with the number of sub-assemblies and the number of child components in these sub-assemblies, are given in the table below.

DJI Inspire Drone System Weight Distribution Analysis

The total weight of the DJI Inspire Drone system (including drone, storage case, remote control & battery) is 7195 grams.

The weight distribution of the assemblies is given in the pie chart below.

- Storage Case accounts for 42% of the total weight of the DJI Inspire Drone system, weighing 3020 grams and is the heaviest of the assemblies present in DJI Inspire Drone.

- The charger accounts for only 6% of the total weight of the DJI Inspire Drone system, weighing 450 grams which makes it lightest assembly.

- Drone weight accounts for 39% of total weight of the DJI Inspire Drone system. The drone weighs 2820 grams (including the battery pack weight and propeller weight).

- Remote Controller accounts for 13% of the total weight and weighs 910 grams (including the device holder weight).

Remote Controller Weight Distribution Analysis

The total weight of the DJI Inspire Drone Remote Controller is 909 gm and the weight distribution of sub-assemblies is represented in the pie chart below.

- Remote Controller Casing assembly accounts for 36% of the total remote controller assembly weight, remote controller casing is made up of >PC+ABS< material grade plastic with stamped aluminium trim glued to the casing.

- The Antenna assembly accounts for only 2% of the total remote controller assembly weight which makes it one of the lightest sub-assemblies of the remote controller assembly.

- Controller PCB board, Battery module PCB and GPS module PCB combined accounts for 31% of the total remote controller assembly weight.

The control switch assembly consists of control switch PCB, camera control dial PCB, gimbal dial PCB and other components which accounts for 15% of the total weight of Remote Controller assembly.

Drone Weight Pareto Analysis

- Battery Pack, propeller motor, flight mode actuator and frame sub-assemblies account for 75.1% of the total weight of DJI Inspire Drone aircraft.

- The average weight of each sub-assembly is 72 gm excluding major sub-assemblies like Battery Pack, Propeller Motor, Frame, and Flight Mode Actuator.

- The Battery Pack Assembly consisting of BMS PCB, cells and cell interconnection PCB accounts for 23.5% of the total drone weight.

- The Cooling Fan assembly of the N-Core unit in drone, accounts for only 0.46% of the total drone weight

- The weight of each propeller motor is 140 gm, the weight of the motor (excluding the motor controller PCB) & propeller is 105 gm & 20 grams respectively. The combined of four propeller motors weighs 560 gm which accounts for 19.9% of the DJI Inspire Drone’s weight.

Drone Raw Material Distribution Pareto Analysis

- Plastic accounts for 53.1% of the overall material percentages of DJI Inspire Drone, this plastic weight is majorly because of the storage case and the controller casing materials.

- Carbon Fiber found on the drone boom accounts for 2.7% of the material percentage of DJI Inspire drone.

- Steel is majorly used for fasteners and accounts for only 10.7% of the material percentage of DJI Inspire Drone Inventory.

- The composite material found on the Battery Cell accounts for 11.9% of the material percentage of the DJI Inspire Drone.

- N-core PCBs, GPS Antenna module, Drone Power Board PCBs and Charger PCB all have FRP material content. Hence FRP accounts for 2.91% of all material percentage in the DJI Inspire Drone

- Plastic is the most common material found on the DJI Inspire Drone and the material grades found are >PC<, >PC+ABS<, >PA6+40%< among which >PC< grade accounts for 53% of raw material grade for all plastic components and >PA+40%< accounts only 12% of all plastic components of DJI Inspire Drone Inventory.

Manufacturing Category Distribution Analysis

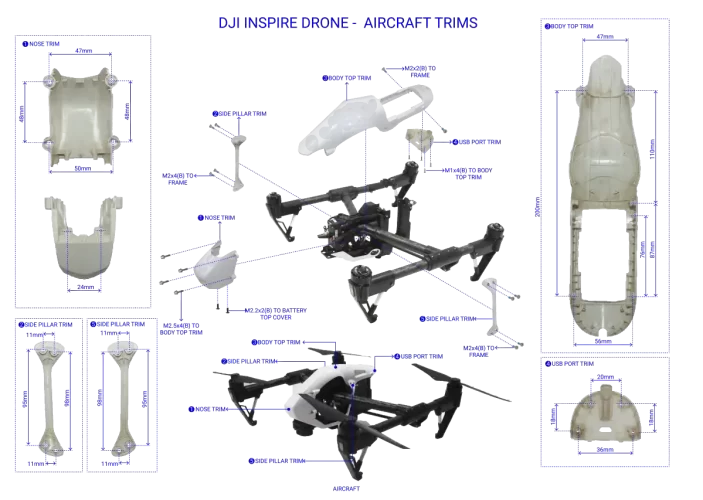

- Injection Moulding accounts for 38% of the manufacturing categories in DJI Inspire Drone. This is because parts like storage case, controller casing drone body trims …etc. are injection moulded, making it the commonly used manufacturing process for most components and parts.

- Carbon Fibre filament is used on Boom rods of the DJI Inspire Drone to provide high strength while also keeping the weight down and accounts for only 1% of the total components of the DJI Inspire Drone Inventory.

- Other than carbon fibre filament, glass moulding and layered manufacturing are also observed and account for 1% the manufacturing process of DJI Inspire Drone.

- Forming, Fabrication and Machining combined together account for 13% of manufacturing categories of DJI Inspire Drone. Stamping accounts for 7% of the total process and is because of the heat dissipation sheets.

Part Coating Distribution Analysis

- Zinc coating accounts for 59% of all part coating types and is more commonly found on fasteners.

- Whereas Zinc dichromate accounts for 6% of all part coating types, this coating type is observed on the Storage Case Lockset parts.

- Black coating accounts for 12% of all part coating types, it is found in fasteners.

- Some aluminium parts used in flight mode actuator frame are painted which accounts for 21% of all the part coating types.

Fastener Distribution Analysis

The following chart represents the total number of fasteners used on the DJI Inspire Drone.

- DJI Inspire Drone aircraft uses 57% of the total fasteners found in the entire assembly. Since most of components of the drone are mounted using bolts.

- Remote controller consists of 35% of the total fastener count since the main controller PCB, control switches input PCB, GPS module PCB and Antenna PCB are mounted using bolts.

- The fasteners of the charger account for only 3% of the total fastener count since major components of the charger are not mounted bolts and bolts are only used to mount the heat sinks of the charger PCB. Hence less fasteners are used in charger.

- The storage case accounts for 5% of the total fastener count because the number of components present in storage is only 35 hence the bolts count is also low.

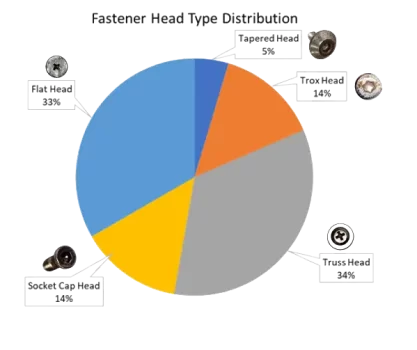

Bolt Head Type Distribution

- Truss head type fastener bolts account for 34% of all fastener head types of DJI Inspire Drone Inventory. This type of fastener is commonly used on remote controller components.

- Whereas flat head type fastener bolts account for 33% of all fastener head types.

- The fasteners of the charger account for only 3% of the total fastener count since major components of the charger are not mounted bolts and bolts are only used to mount the heat sinks of the charger PCB. Hence less fasteners are used in charger.

- Socked cap head and Torx head types both account for 14% each of the all-fastener head types.

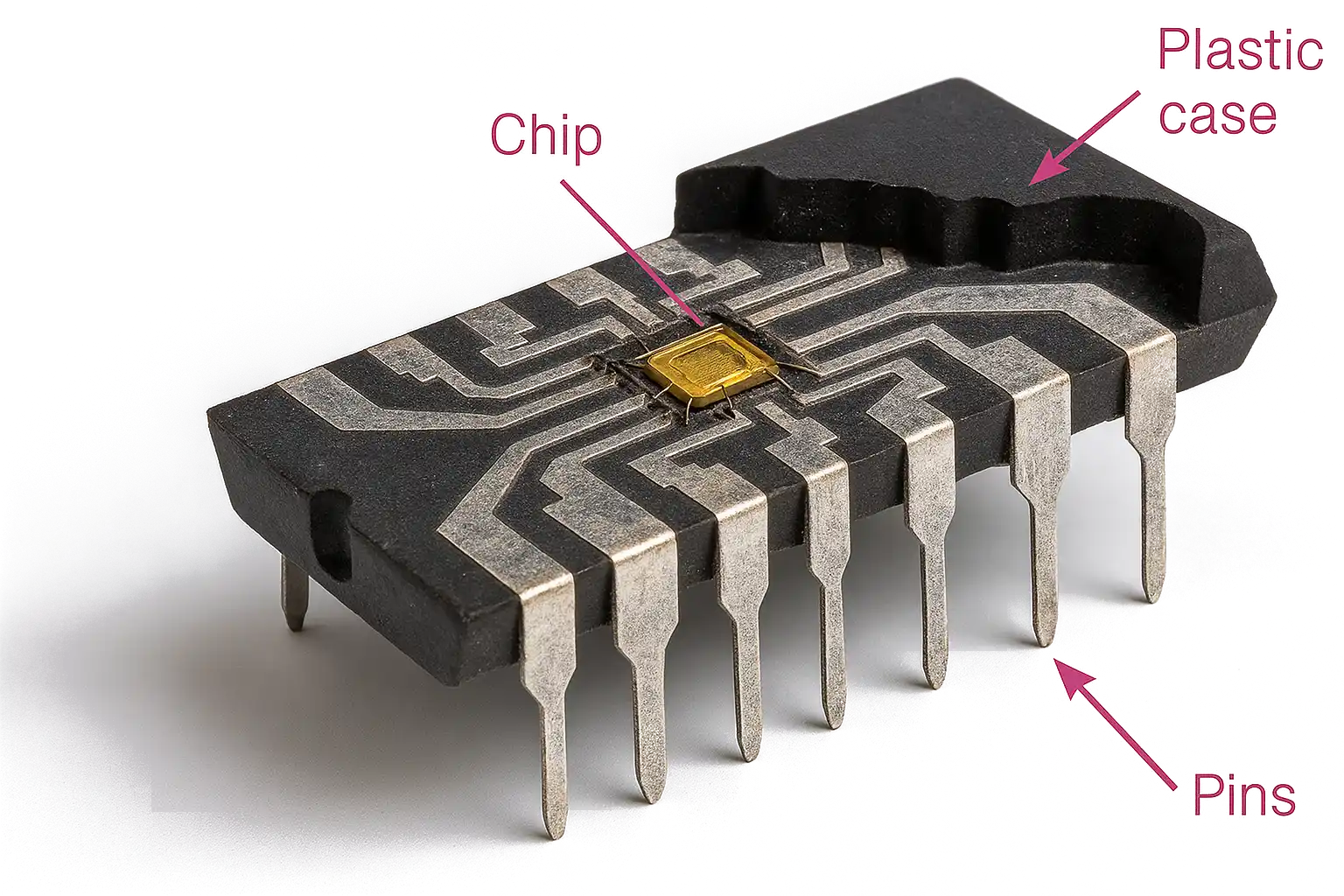

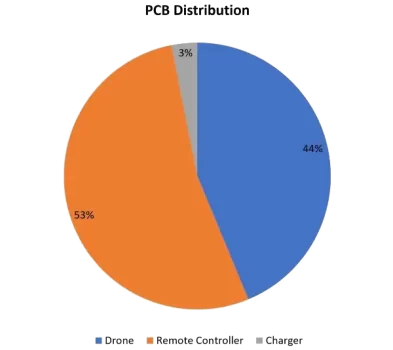

PCB Distribution Analysis

- Remote Controller account for the 53% of all the PCBs found on the DJI Inspire Drone System. PCBs on the remote controller include the main controller PCB, GPS antenna PCB and many control switch PCB where every input control switch has their individual PCBs.

- Whereas DJI Inspire Drone Aircraft accounts for 44% of total PCBs which includes the motor controller PCB, power board PCB, GPS antenna PCB, N-Core PCBs and many more.

Architecture Study of DJI Inspire 1 Drone

- PACKAGING

- POSITIONING

- INTERFACE

- FUNCTIONAL DIAGRAM

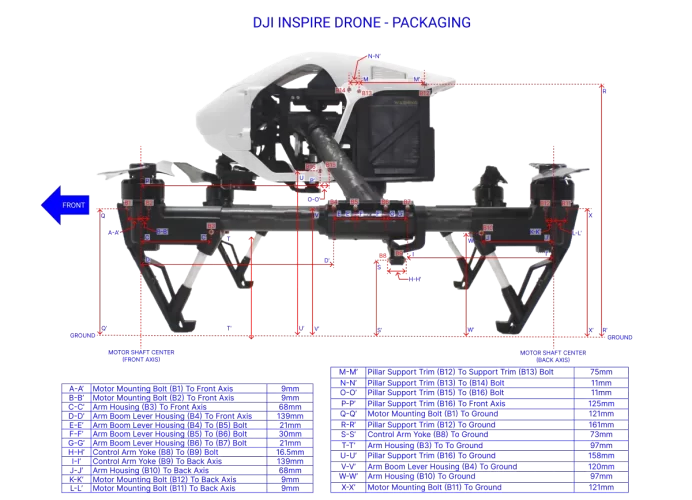

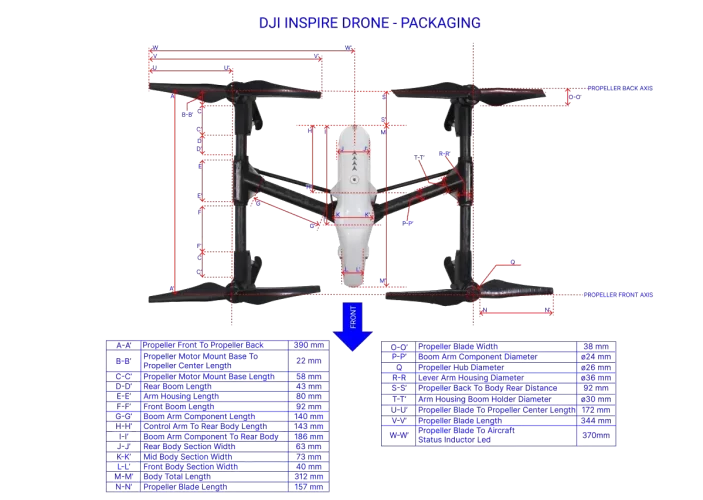

PACKAGING DIAGRAM

In Packaging, various aspects related to major dimensions such as propeller to propeller distance, front motor shaft to rear motor shaft distance, and similar dimensions which are critical to the design and functionality of the system are mapped. 14 packaging diagrams in all the orthographic views were captured.

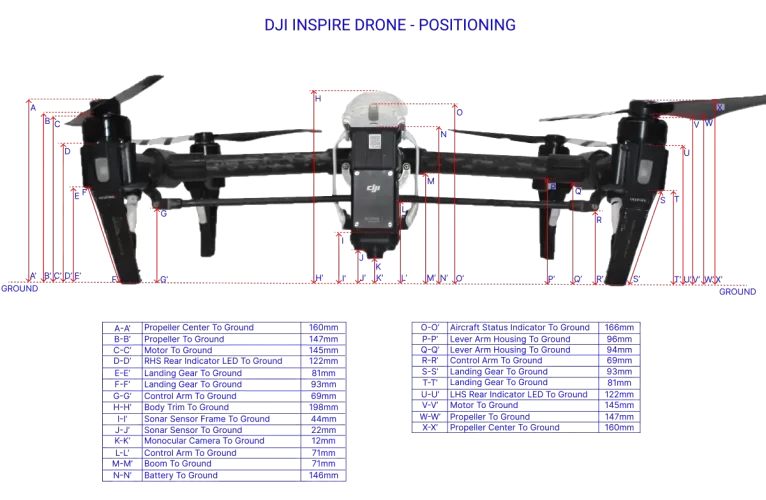

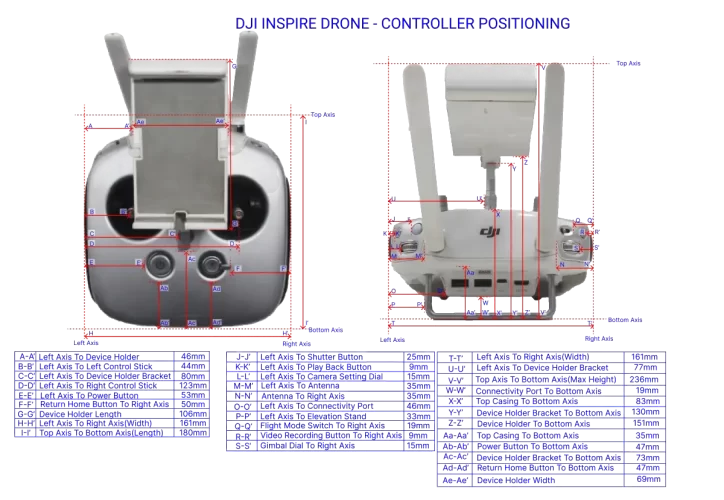

POSITIONING DIAGRAM

The positioning diagram consists of all critical dimensions of the components of a system with reference to the ground or a reference plane. 20 positioning diagrams were prepared. These measurements help in understanding the overall positioning of systems and their sub-parts.

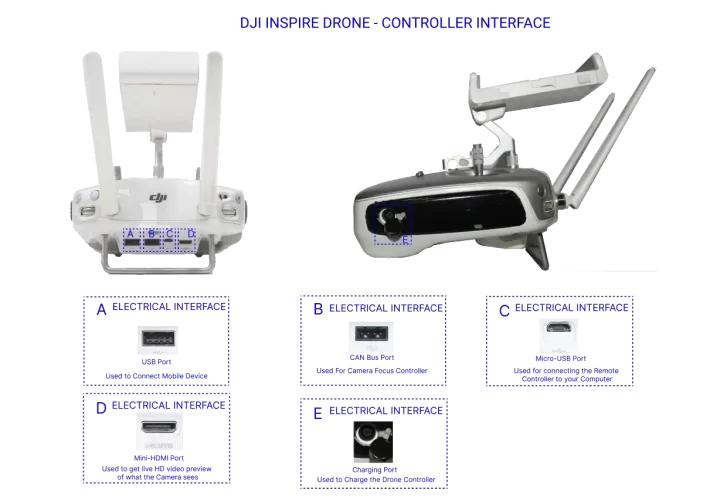

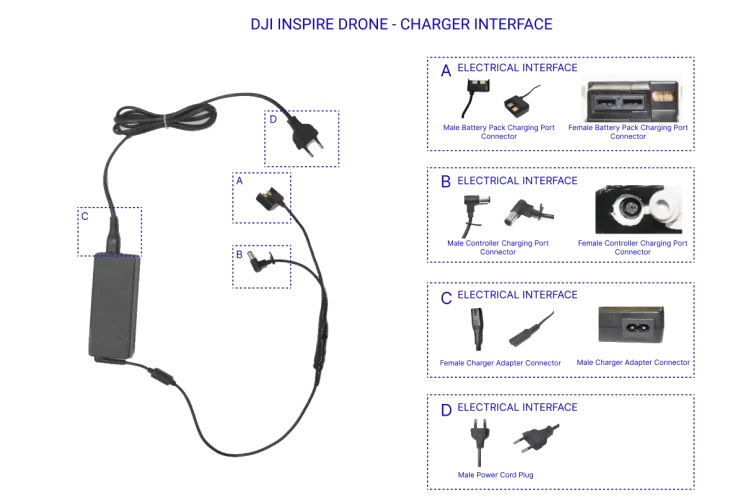

INTERFACE DIAGRAM

The interface diagram consists of all the details regarding the interface between one system to another system such as the interface connections between battery to the charger, controller to the mobile device… etc. Here all the information related to electrical connections such as connector details, male and female connectors are captured. 5 interface diagrams were created detailing all the captured information of different systems.

FUNCTIONAL DIAGRAM

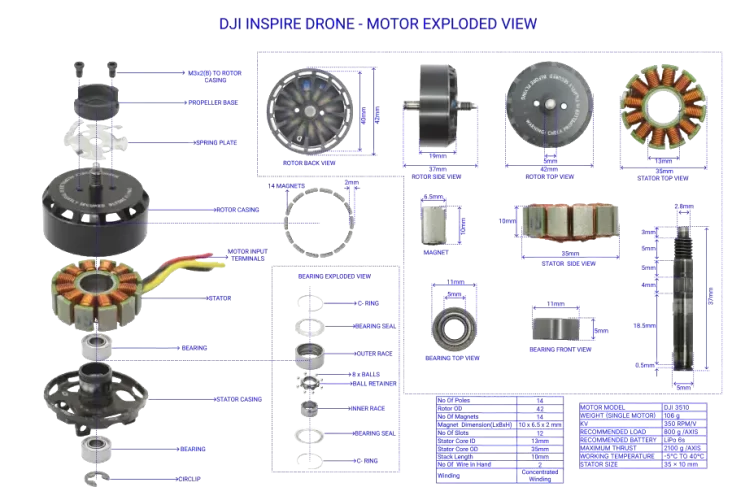

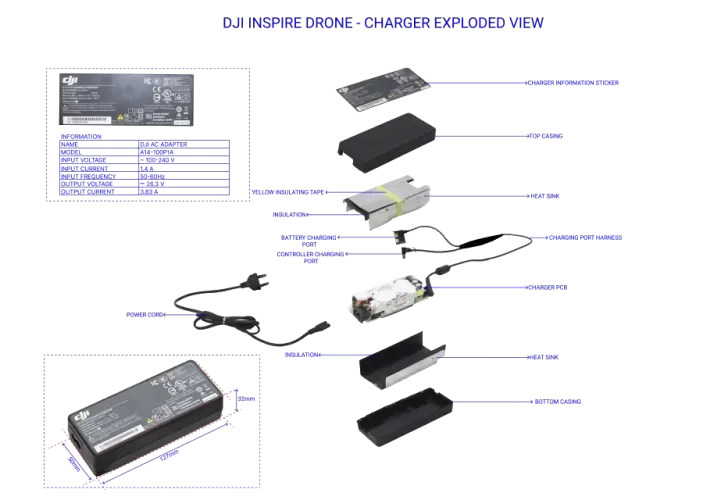

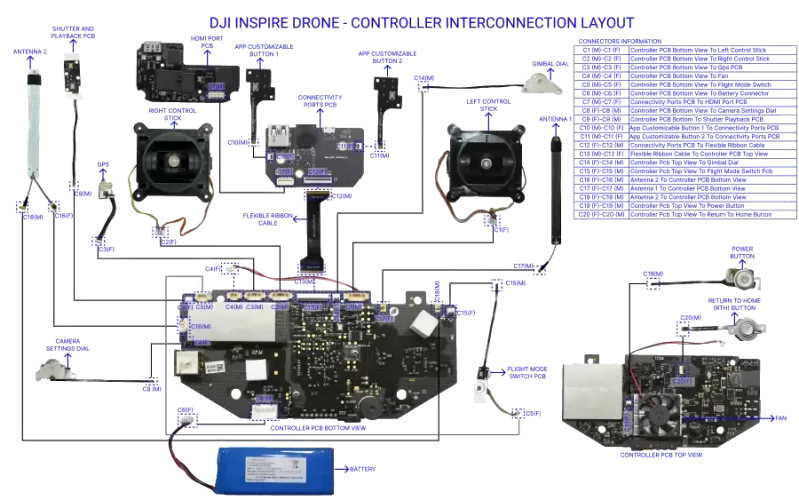

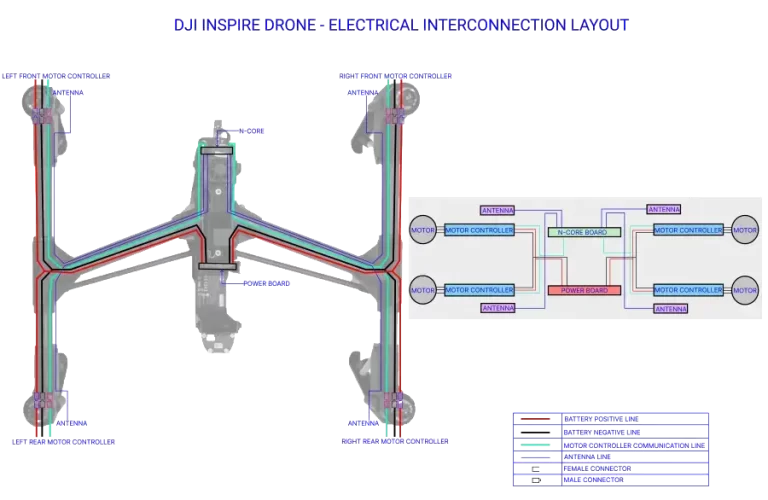

A functional architecture diagram consists of the system’s operational intent and explains the design functionality. There are 4 types of functionality diagrams.

The following are the types of functionality diagrams

- INFORMATION DIAGRAM

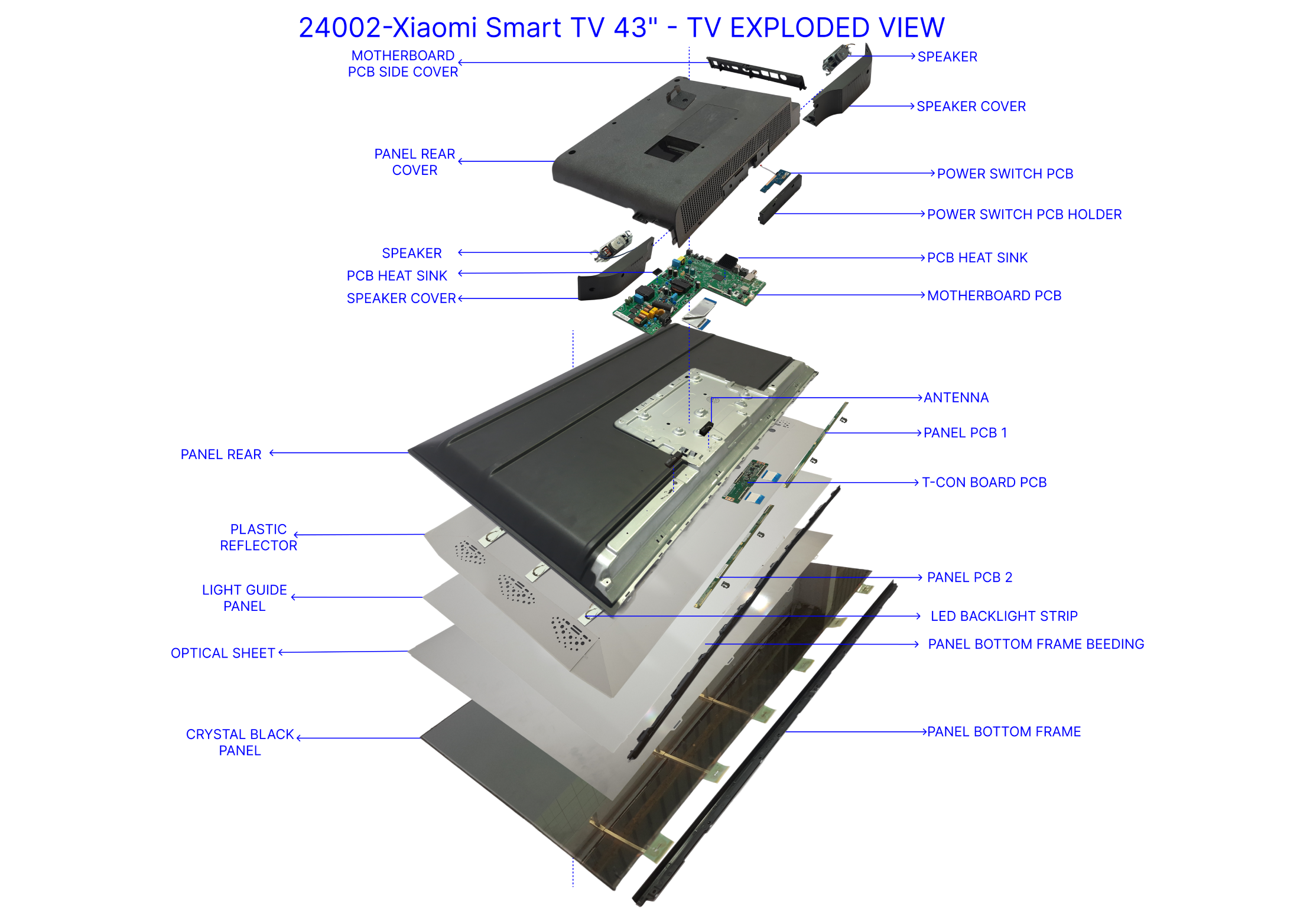

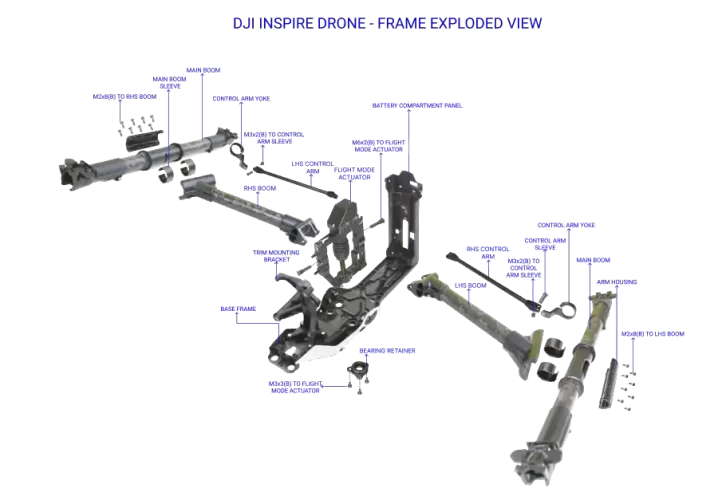

- EXPLODED VIEW

- INTERCONNECTION LAYOUT

- PCB LAYOUTS

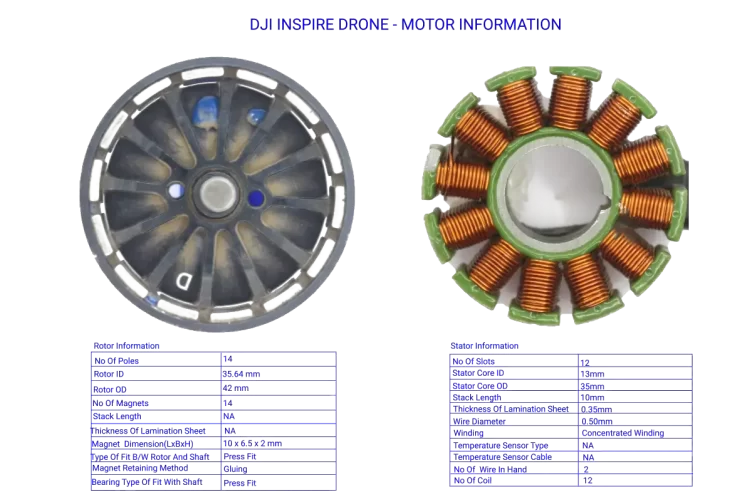

INFORMATION DIAGRAM

It consists of all the information regarding the system design attributes such as (specification, motor design parameters) which are key for the functionality of the system. Here we have created 6 information diagrams for DJI inspire drone

EXPLODED VIEW

Exploded view provides a deep dive into the system integration and part positioning to understand the in and out of the system and explain how the parts are connected to each other. Here we have created 13 exploded view diagrams of drone, controller, storage case and charger.

INTERCONNECTION LAYOUT

Interconnection Layout is used to explain the connection between the electrical and electronic systems of the product. A total of 6 interconnection diagrams have been prepared for systems like controller and Drone. These diagrams are useful in understanding the design complexity of the product.

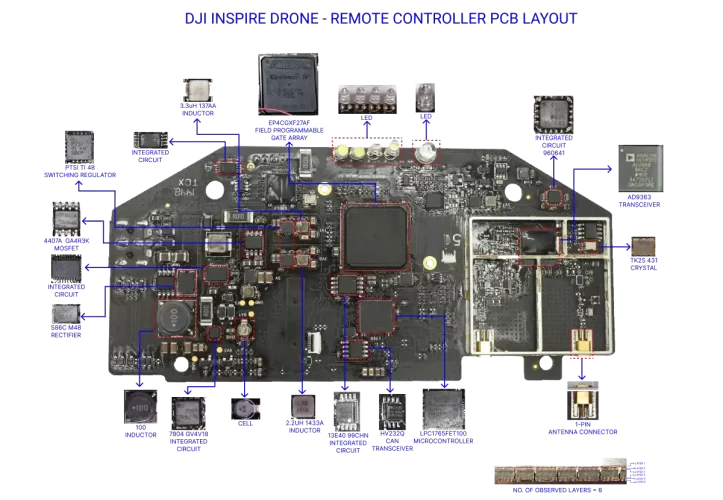

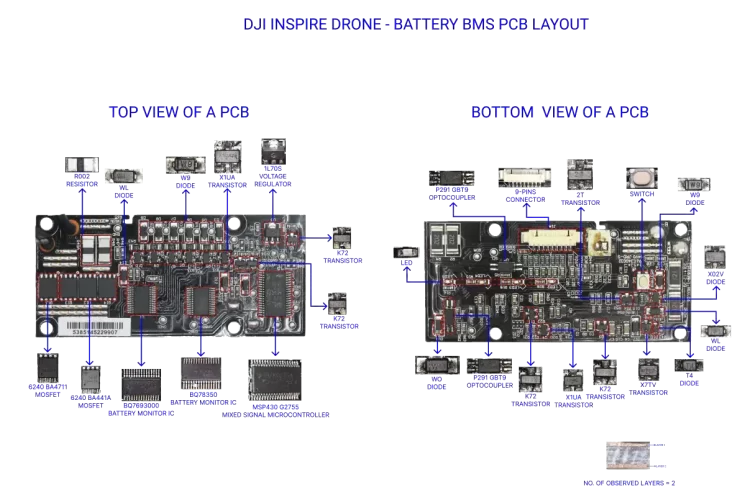

PCB LAYOUTS

PCB Layout diagrams are prepared to represent all major components of PCBs. These diagrams represent components present in a PCB such as microcontrollers, microprocessors, Integrated circuits, connectors … etc. it also specifies the location of components on the Physical PCB. A total of 10 PCBs layouts are prepared.

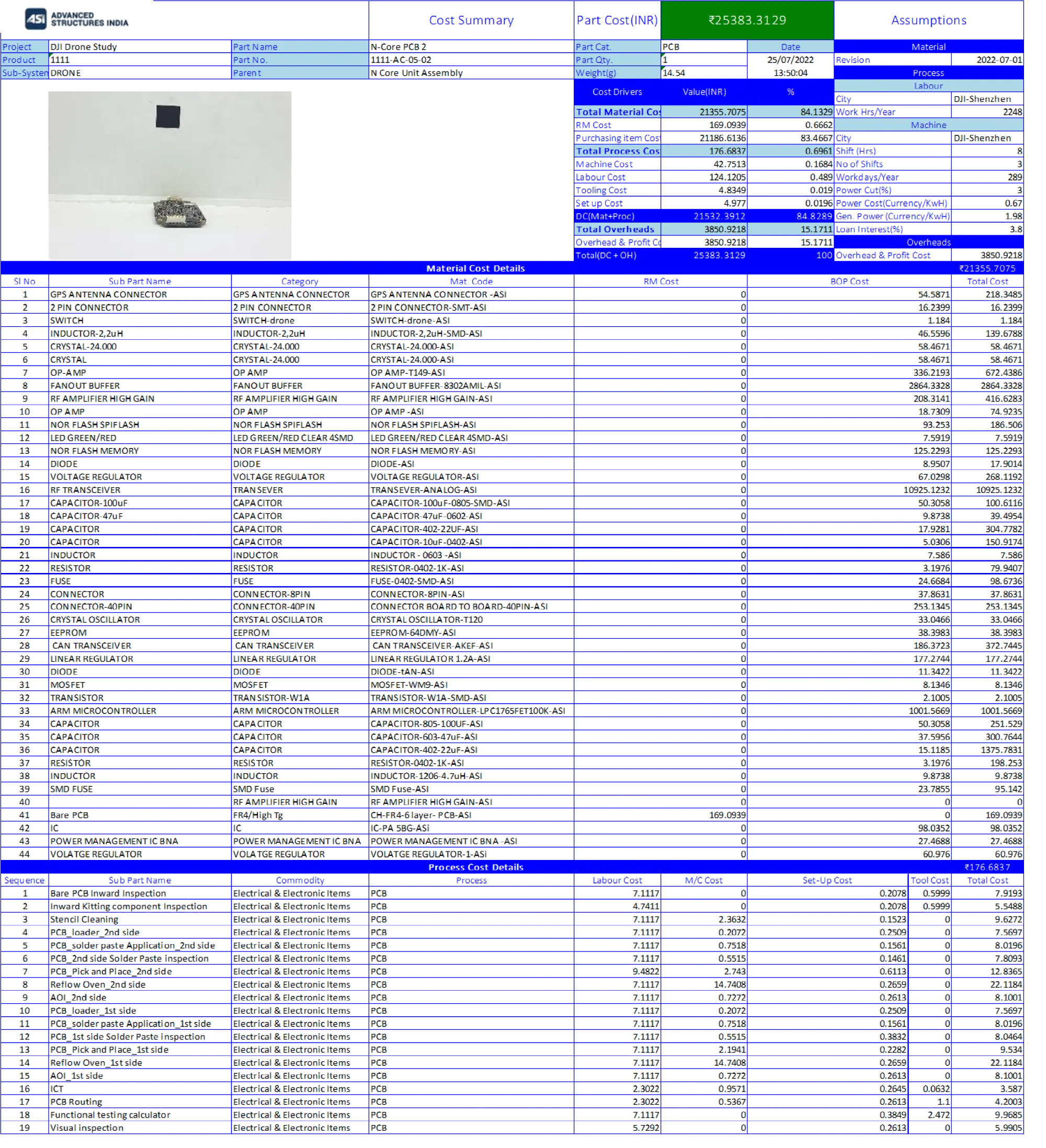

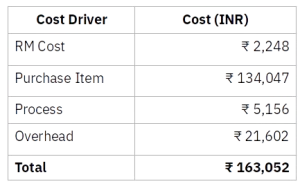

Should Costing of DJI Inspire 1 Drone

A Detailed Should Costing of DJI inspire drone was performed and the following are the outcomes of the study. The manufacturing cost of the drone was found to be 1,63,052 INR and the following were the consideration for the study.

- The Drone was manufactured in China

- The volumes considered for the activity were 25,000 annually

- The latest Material rates and rates required for MHR calculations were taken for Q2 FY22-23.

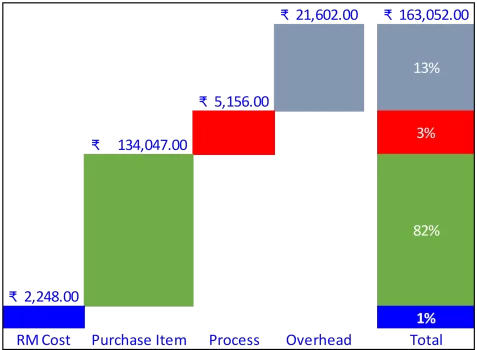

The cost split up of various cost drivers for the manufacturing cost are as shown

The total cost pareto of the drone is present below:

- Analysing the DJI inspire drone system cost, it is observed that 80% of the cost is due to the presence of electrical & electronic components in various sub-systems of the drone.

- The major portion of this cost (68%) is consumed by the drone sub-assembly such as vision position sensors, transceiver, PCB, GPS antenna, and controller are high-cost items.

- Drone weight accounts for 39% of total weight of the DJI Inspire Drone system. The drone weighs 2820 grams (including the battery pack weight and propeller weight).

- The other position in the Pareto (22%) is occupied by the controller sub-assembly where parts such as the data processing PCB which receives the signal from the drone and the HDMI port PCB which help in enhancing the quality of the data suitable for larger screens, without it the data quality would be low.

- Also evident from the sub-system-wise split-up of the cost, the Drone sub-assembly has the highest cost followed by the control subsystem.

Drone sub-assembly:

- N-Core PCB had the highest child part cost 43%. Its cost is due to the presence of an RF transceiver- which sends and receives a signal from drone to controller.

- Another is due to the presence of a clock-out buffer, which is used to create multiple signals and distribute them to other components.

- The CMOS image sensor in the vision position sensor contributes to 68% of the cost and a micro-controller

- The motor controller of the drone has a flash micro-controller, transceiver-IC, and an N-Channel MOSFET contributing to 44% of the cost of the component.

- The Trims & the carbon support structure constitute 4% of the drone sub-assembly cost. PC, PA66 & PP were the materials used for trims & 95% of the cost is due to the presence of carbon fibre filament pipes which are used for their low weight: strength ratio.

Controller sub-assembly:

- The Pareto of the controller assembly has the following electronic components contributing to its higher cost:

- The data processing PCB is used to receive the signal from the drone. The receiver IC contributes 36% of the part cost, the other 19% is because of the presence of 220 & 22PF SMD capacitors.

- The other high-cost item is the HDMI port PCB used for enhancing the quality of the data suitable for larger screens. The RFID module amounts to 25% of the part cost and 14% of the cost is from the DC-DC regulator & touch screen controller.

The direct material costs and process costs for the part are mapped in detail as shown below:

- These costs have been arrived at by taking a select set of assumptions related to material costs, supply chain considerations, manufacturing locations, etc.