LCV Steering Pump Teardown & Benchmarking

EV Charger Teardown & Cost Driver Comparison

Motor Controller Teardown & Cost Driver Comparison

*All data/graphs/trends/images presented on this page are dummy/heavily masked/edited to remove specific details. They are intended only to showcase sample outcomes of such activities.

Recently we conducted a teardown for VA/VE exercise on 2W Controller from two different OEMs, while doing so we formulated a strategy to reduce the cost of controller by 7%.

At Advanced Structures India we use Engineering Intelligence augmented with proprietary xcPEP tool to map material, architecture, manufacturing, complexity and cost in a comprehensive manner. The cost drivers are compared up to the last level of detail & ideas for cost reduction are generated.

This blog will focus on our findings while comparing the EV Controller for 2 Vehicles in following areas:

- Controller’s packaging study & its comparison

- Component complexity in Controller and Component Size Range in PCB

- Cost Analysis

- Comprehensive comparison & cost reduction through xcPEP

Competitor selection is an important step in order to generate large number of ideas as we can have access to industries most cost-effective solutions that can be challenged with your practices. Generally, the cost reduction activities for products done in absolute turn out to be 40% less effective than a comparative study.

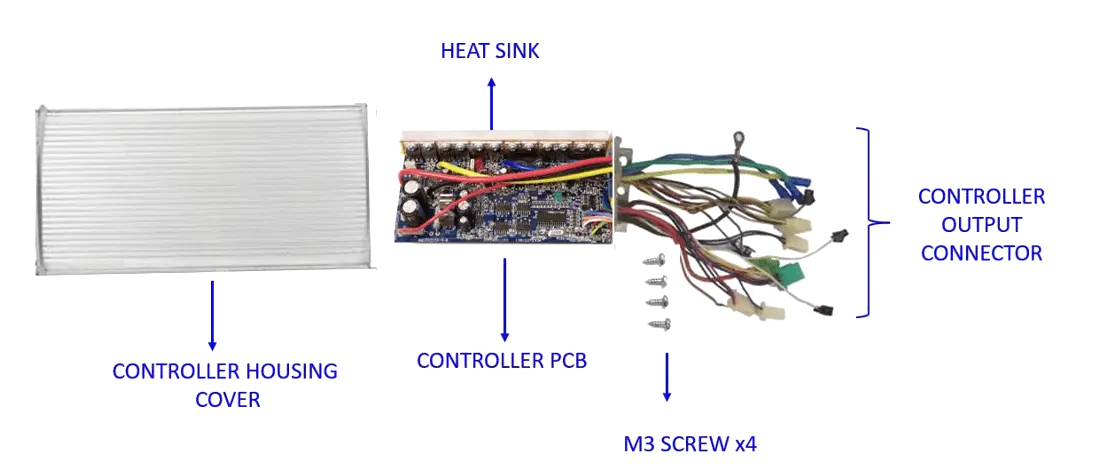

Controller Packaging Study & Its Comparison

Schematic are created while doing the teardown and these views are studied in side-by-side analysis while doing the comparison.

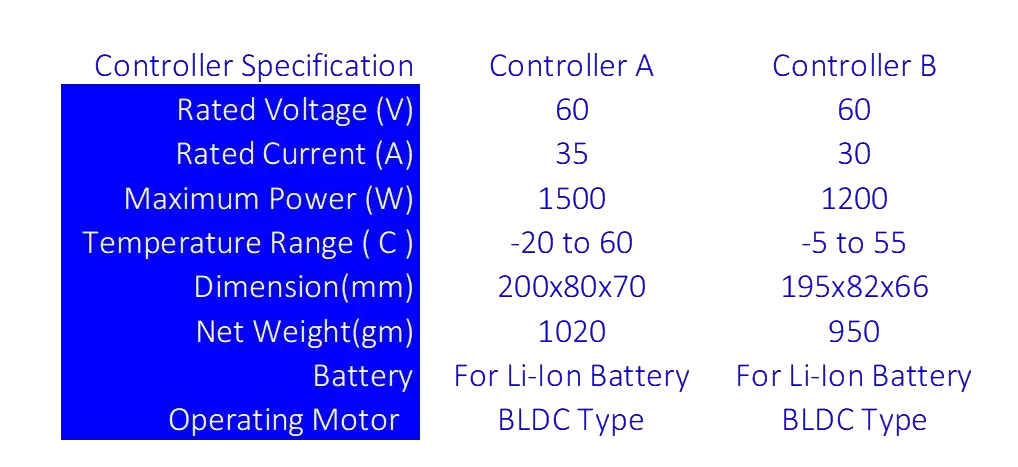

While comparing both the Controller it is observed that the packaging design of Controller are much more complex in Controller A, i.e., Controller A’s housing is a 3-piece design with higher thickness value (by 0.8 mm) compared to 2-piece design in Controller B resulting in high housing weight (more by 18%), also because of 3-piece design, Controller A requires a greater number of fasteners (more by 4) for assembling it. This affects the manufacturing cost and time. Although the Controller B is of slightly higher spec. (Refer Spec Table Below)

Also, assembly of harness was observed to be more complex in Controller A when compared to Controller B. Also in Controller A, Female’s connector was provided to for further connection which is available less in number in controller B. Increasing the cost of assembly by 6 %.

In Controller A, the heat sink provided is of more thickness (by 1.8 mm) in comparison to Controller B heat sink. Heat is attached to aluminium housing with help of thermal paste.

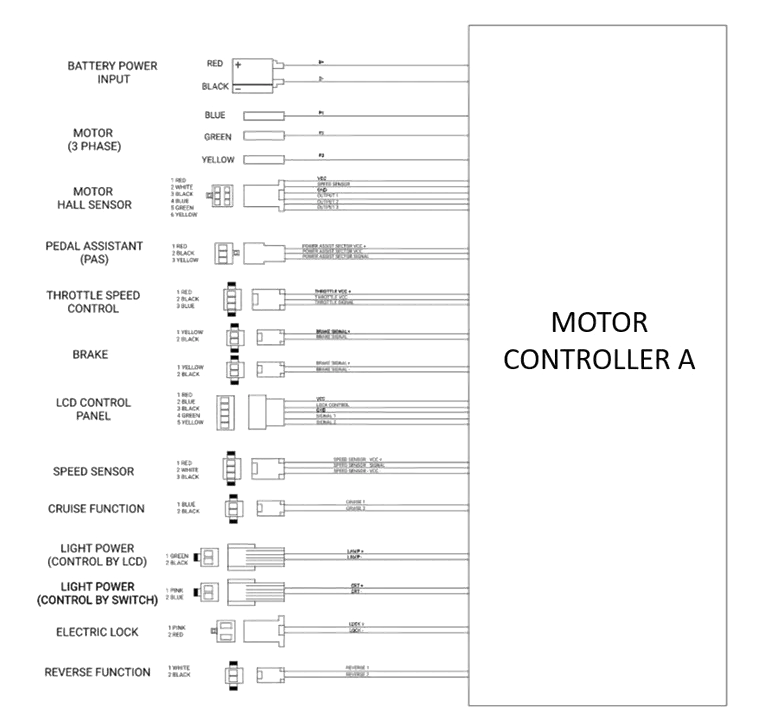

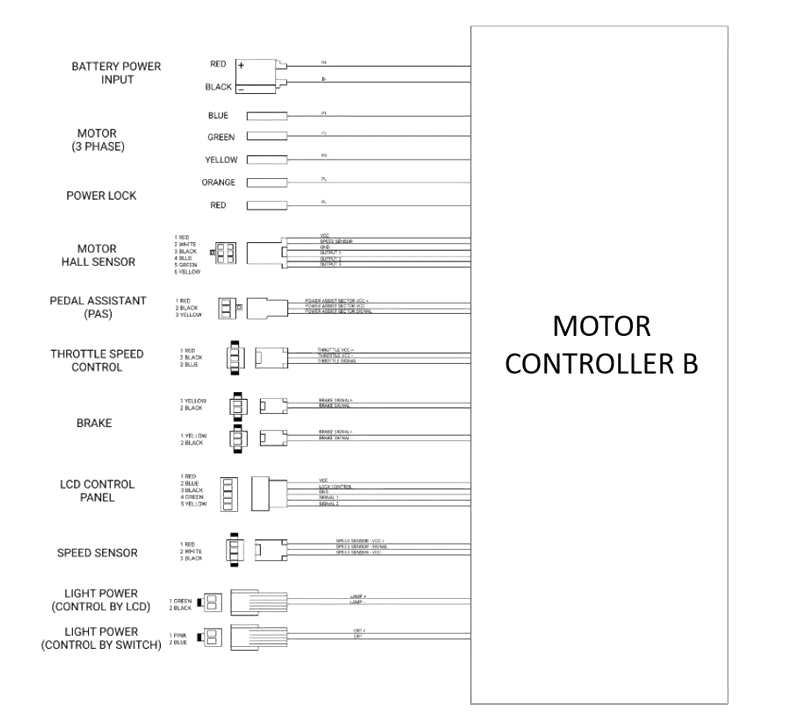

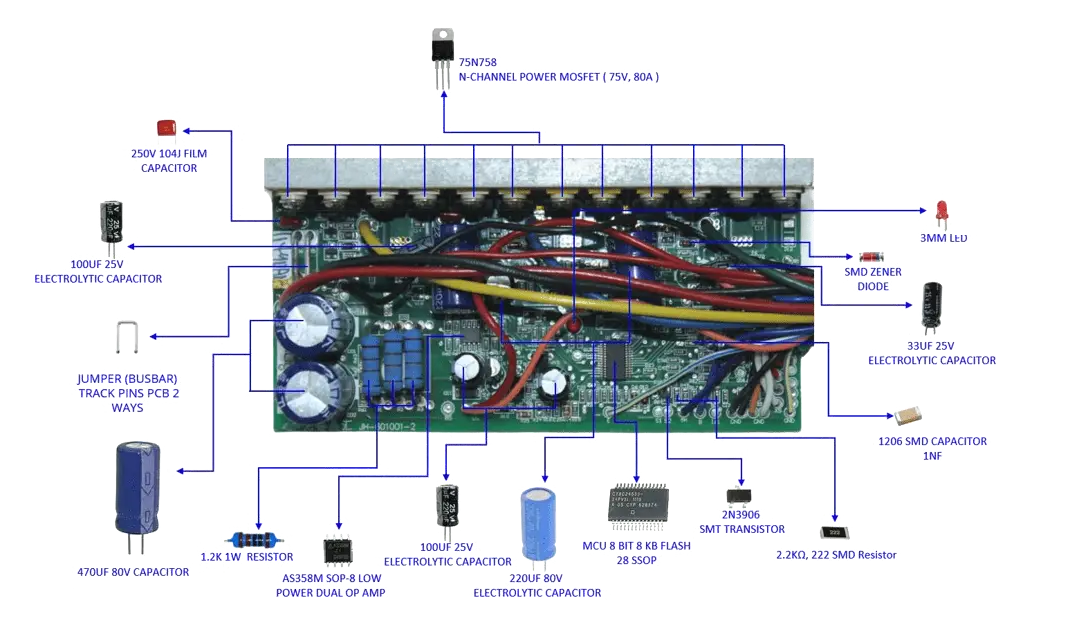

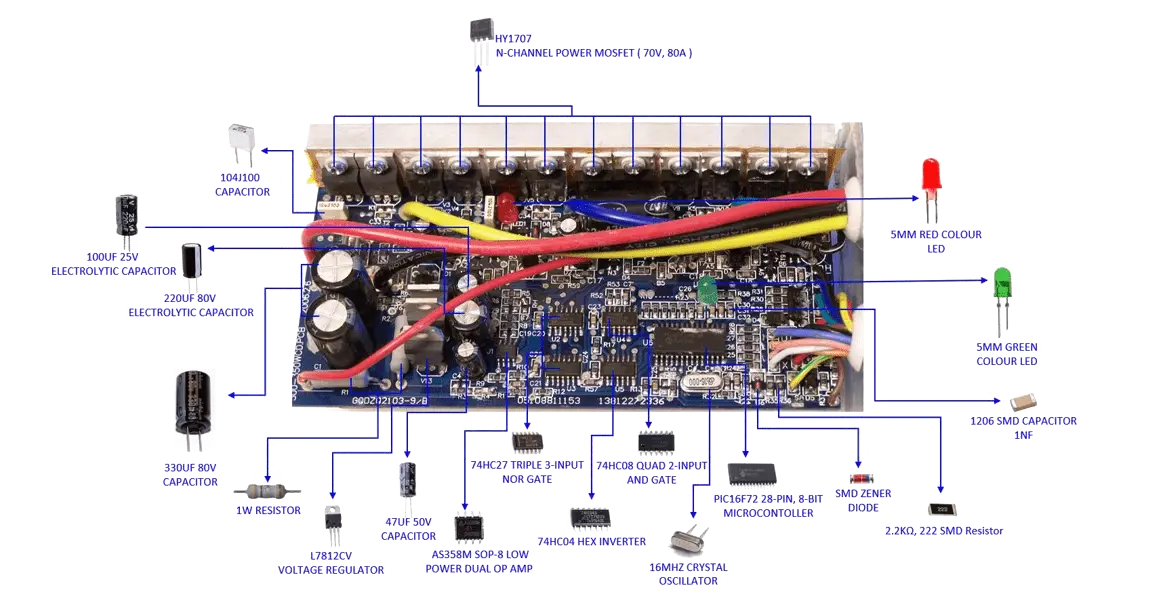

A block and signal diagrams are created for the PCBs for comparison and studying the circuit.

Controller A

Controller B

Even though the Controller specification were found to be nearly similar the overall philosophy of PCB circuit and usage of components were quite different.

Controller B is provided with 3 extra ICs a 3 input NOR gate, hex inverter and quad 2 input and gate. These ICs are not observed to be present in Controller A.

In Controller B function for cruise control and reverse were not observed.

Component Complexity in Controller and Component Size Range in PCB

While studying the complexity of Controller, it is observed that Controller A has 52 components compared to 23 components in Controller B leading to 62% higher complexity in Controller B (except PCB components).

Number of components were higher in PCB of Controller A (161 Components) than PCB of Controller-B (138 Components) leading to higher complexity of the circuits, assembly & size of the PCB.

Also, while studying component size and component spacing it was observed that in PCB of Controller-A, 62% of component size were used in range 0-2 mm while in case of PCB of Controller-B, only 50% of component was found in the range of 0-2 mm.

PCB – Controller A

PCB – Controller B

Thumb rule says a lower quantity of component and larger size component’s usage is economical because assembling them on board will require a machine with lesser tolerance and better precision. Similarly on PCB packing components closely again increase the cost of assembly although it decreases the board size.

So, based on the basis of this analysis multiple suggestions were made to the client where consideration was to check the feasibility of an increase in component size and spacing.

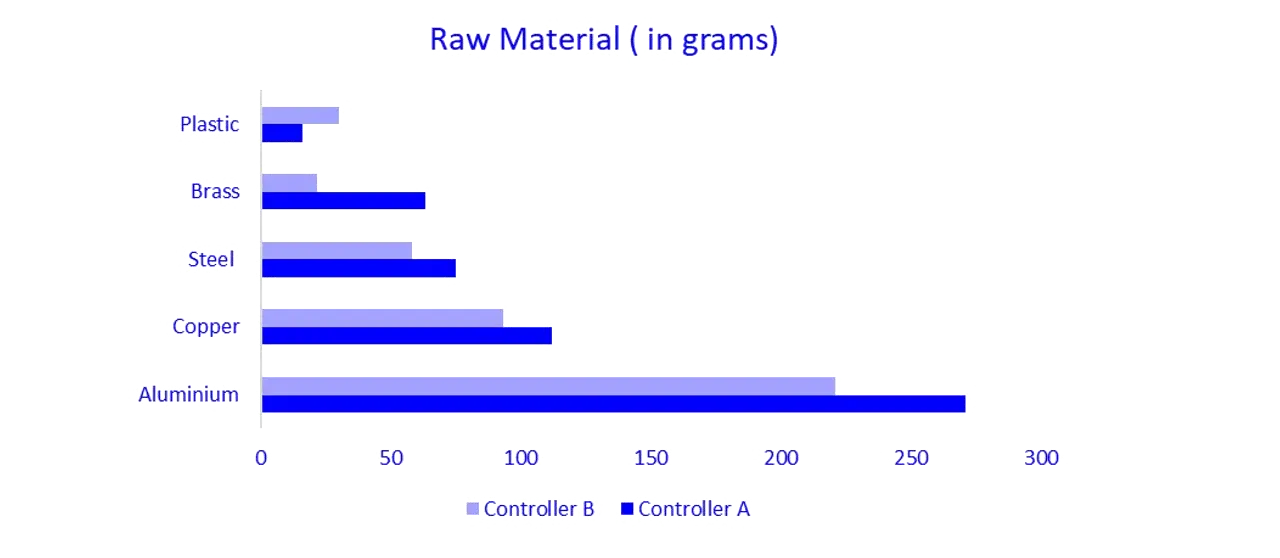

Material used in Controller and PCB

Analysing the material present in both the Controller, it is observed that an extruded aluminium casing present in Controller A is thicker in comparison to Controller B (by 0.8 mm). Which results in lower cost of Controller casing in Controller B by 20%.

Also, steel weight observed to be higher in Controller A, as two steel plates are provided to close the aluminium casing at the ends, where in Controller B the housing only is a box type structure where just one plate is provided at the end which required to close it. This result in higher assembly weight in Controller A by 6 % and cost by 11 %.

As per the spectroscopy result, we found that both boards on controller were FR-5, although we can although as per our previous studies Charger PCBs and other controller we found FR-4 are also being used. Since the working environment conditions were the same for both on other studied PCBs. We can look for FR-4 as an alternate material which will give 10- 15 % of cost saving on board material.

Cost Analysis:

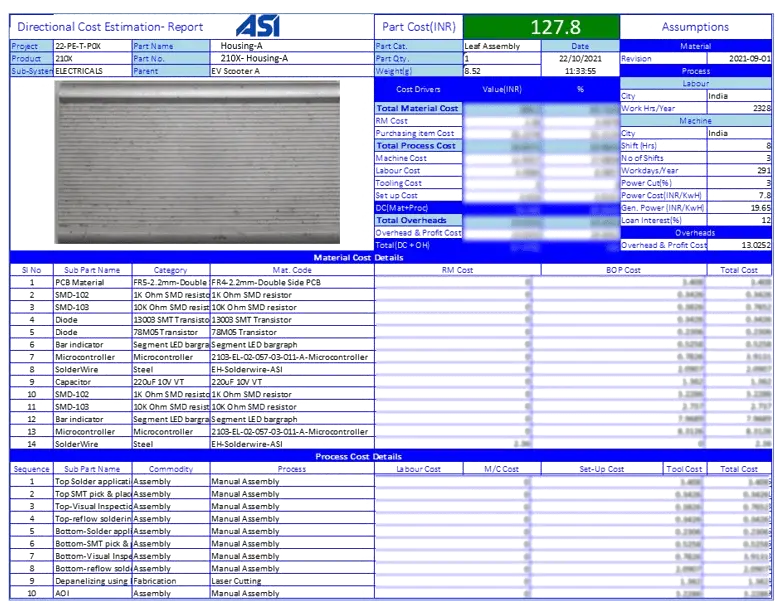

Should cost (SC) of both the Controller were estimated on our xcPEP costing module with pre-configures cost models. It was found that due to high complexity and more number components of Controller A the cost was on the higher side when compared to Controller B. Following images are the downloaded reports from xcPEP costing module.

Comprehensive comparison & cost reduction through xcPEP

Mainly the strategy will be followed in absolute terms on one product or in comparison with competitor product.

Bill of Material (BOM) generation:

We map critical data of base product & competitor product with high quality images to generate a Bill of material (BOM) by using our inbuilt xcPEP tool

xcPEP is our eXtremely Comprehensive Product Engineering Platform with inbuilt tools backed by machine learning trained on automotive component data, to compare data and generate cost reduction ideas.

Circuit Diagram/Schematics

We analyse the product architecture, packaging method by using graphically designed circuit diagrams.

SCHEMATICS OF MOTOR CONTROLLER

Data Analytics

We analyse & compare the generated data (BOM) of the client and competitor w.r.t weight, material, dimensions, fasteners usage, brackets usage, which are compared and analysed with graphical plots at the sub-assembly level as well as at the product level, using xcPEP tool

Cost Estimation

We estimate the directional should cost of 100% components to identify the three major cost drivers for every part Raw material, Process and Overheads. Later we compare the cost drivers at granular level for idea generation.

Cost saving idea generation using xcPEP tool

The xcPEP tool generates cost saving ideas from the generated BOM at product and level, as per user requirement. The Engineers at ASI evaluates the generated ideas, adds value & does feasibility to the idea generated by the xcPEP tool.

From the above-mentioned methods and idea suggestions, we have generated ideas on Controller A and 41% of the total generated ideas were implemented. This resulted in total cost savings of 9.3 % of Controller A.