Starter Motor Teardown and Feature Study

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publishing.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

Explore xcPROC →This blog contains our findings on starter motor consisting of:

- Introduction to starter motor and its types.

- Features and specifications mapped in starter motor.

- Bill of materials generated from xcPEP.

- Architecture and layout study of starter motor.

Introduction to starter motor and its types

Types based on Gear reduction methods:

- Direct Drive Electric Starter Motor

- Gear Reduction Type Starter Motor

Types based on armature:

- Permanent Magnet armature type

- Field Coil armature type

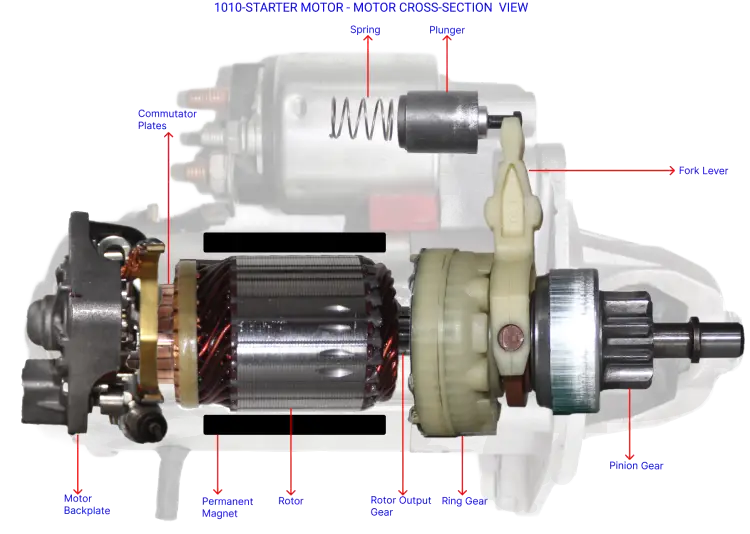

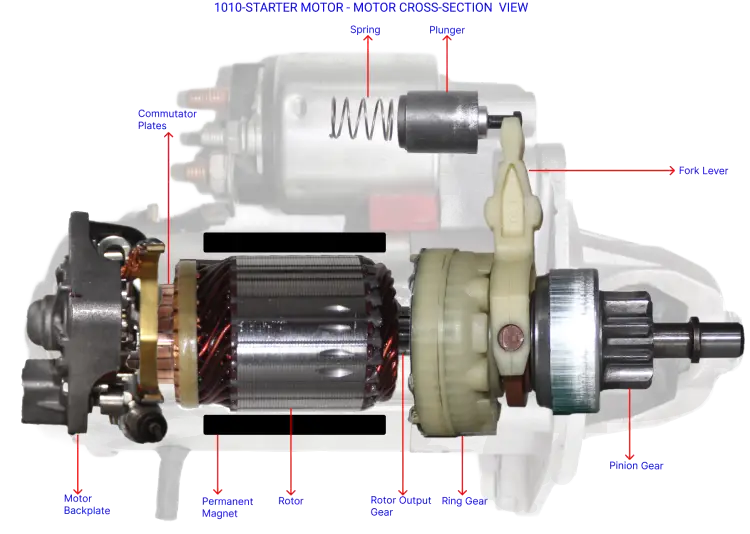

The motor considered in this activity is of gear reduction type where planetary gear set is used for torque multiplication since the size of the flywheel is large and higher torque is required to rotate it.

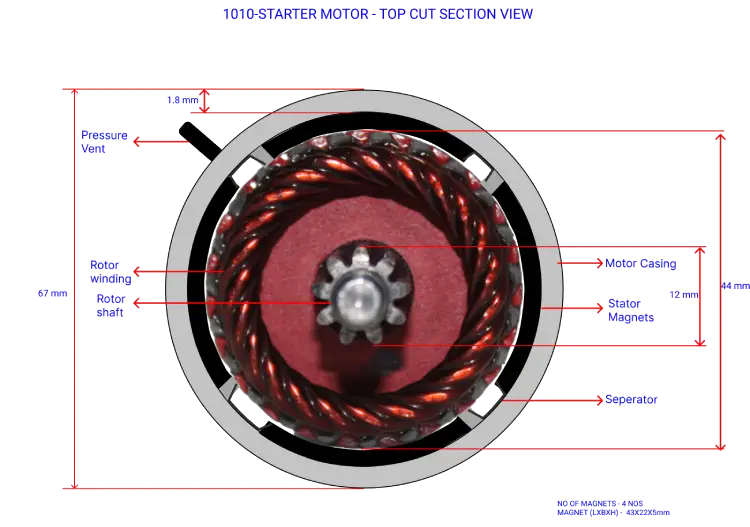

The starter motor used for study is observed to be a permanent magnet armature type as it is provided with permanent magnets which acts as a stator and rotates the rotor made up of electromagnets.

Features mapped in starter motor

Features are mapped using xcPEP tool.

The features are divided into two categories:

- Product level features.

- Part level features.

Product level features:

Breather or pressure vent:

Damper provided between solenoid and motor casing:

Ground Provision:

Part level features:

Stator type:

Four permanent magnets which acts as a stator are glued and separated using clips inside the permanent magnet casing which helps in rotating the rotor made up of electromagnets.

Gear Reduction type:

Spline gear:

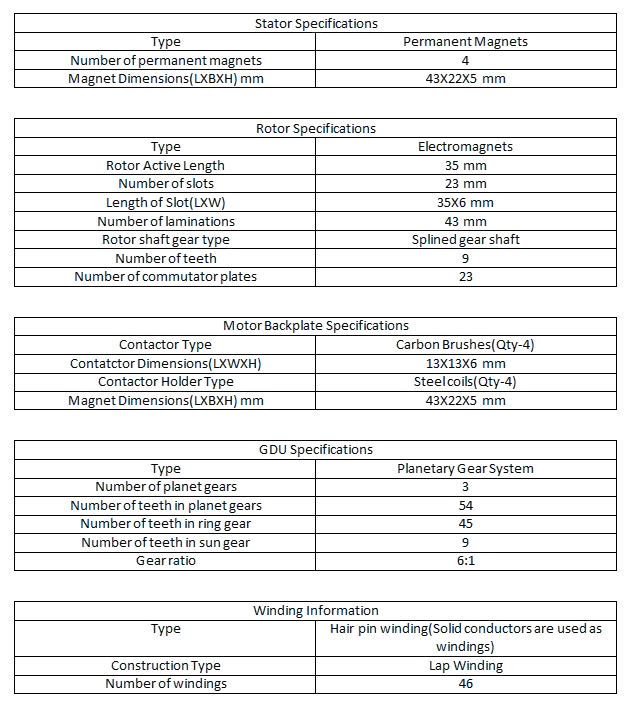

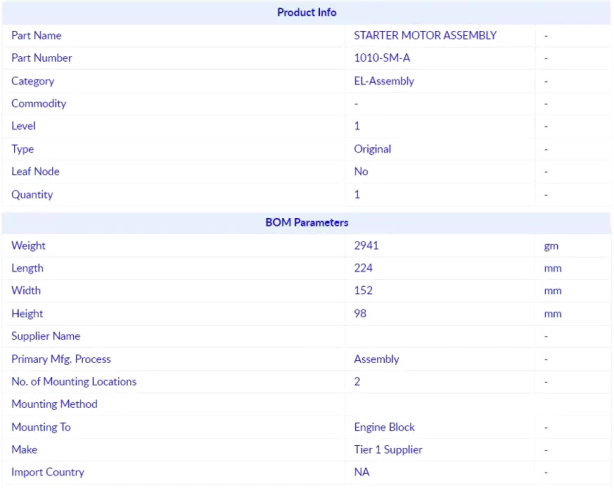

Specification mapped in starter motor

- Product level specification

- Part level specification Some of the product level

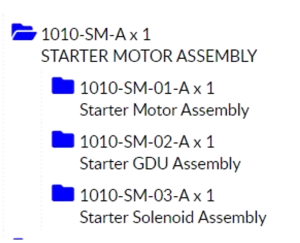

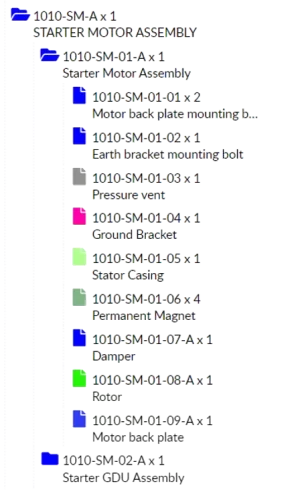

Bill of materials generated from xcPEP

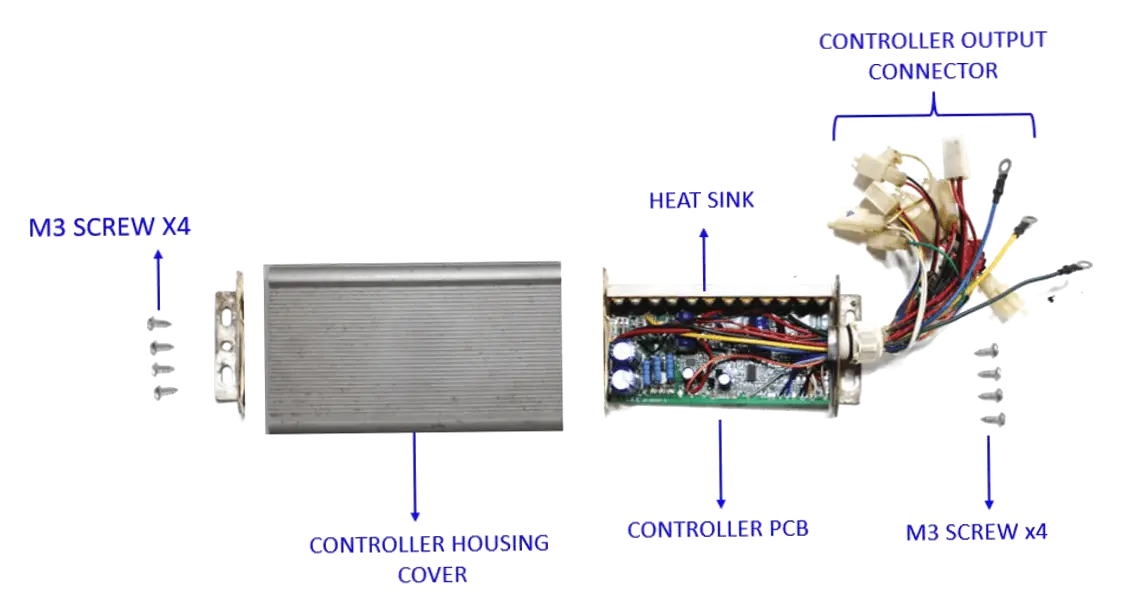

After mapping all the product data, the product is further divided into sub systems for which the same data as the product are also mapped.

The sub system of the product are further torn down to last level and all the individual parts are created under their respective sub systems.

The created last level parts are then mapped with the details like box dimensions, Materials, Surface coating and thickness, Supplier data, Manufacturing process(Primary, Secondary and tertiary manufacturing process) and dependencies.

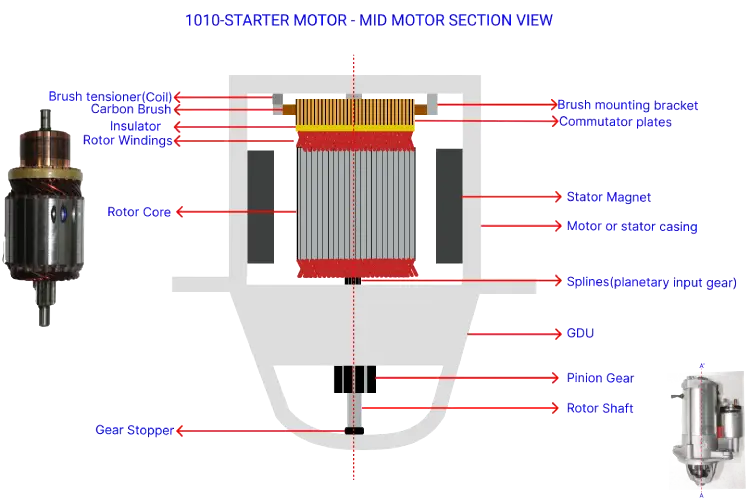

Architectural Study of Starter Motor

Product level architecture is categorised into:

- Packaging diagram

- Interface diagram

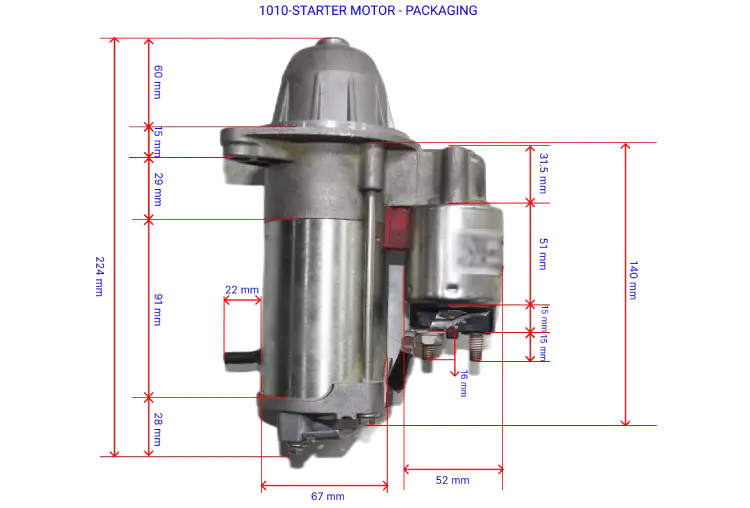

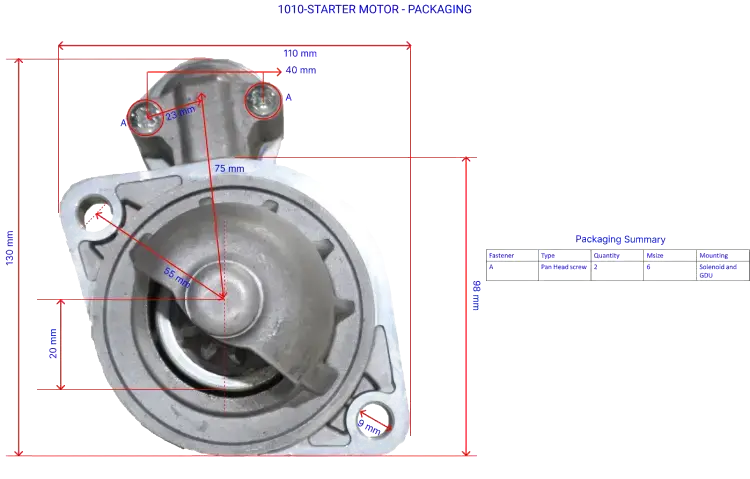

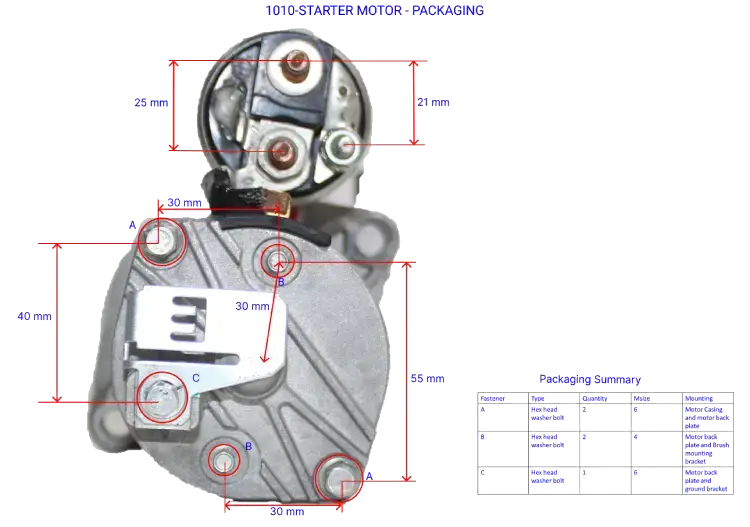

Packaging diagram:

All the major dimensions required to design a part is given under packaging diagram. The dimensions in all the orthographic views are marked.

Summary table is provided where the fastener details such as type, Msize and mounting locations are provided

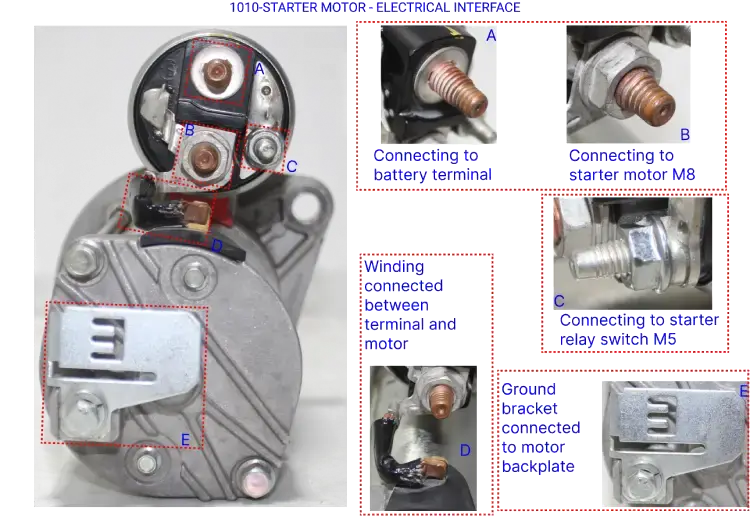

Interface diagram:

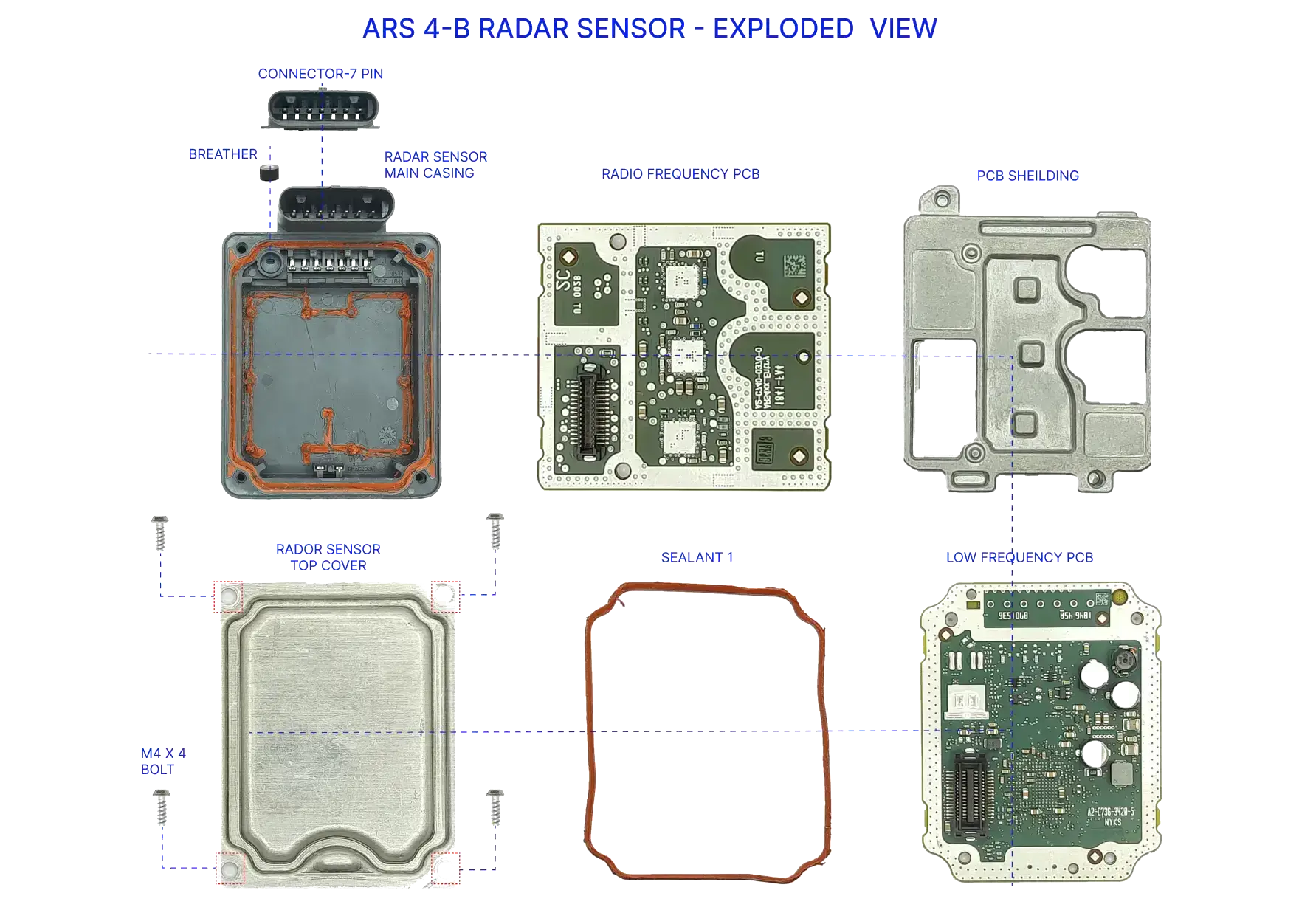

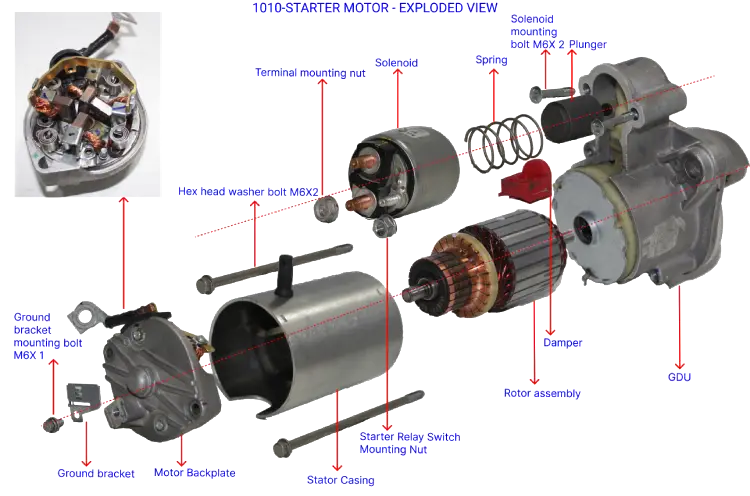

Exploded View

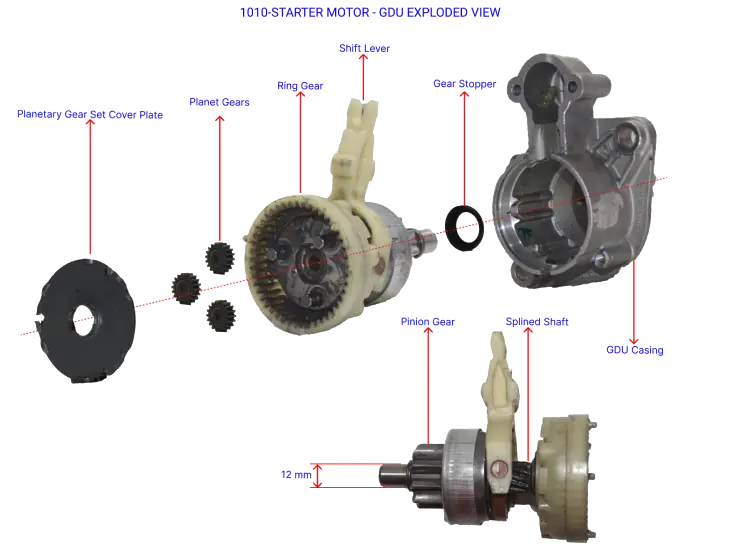

Exploded View of GDU

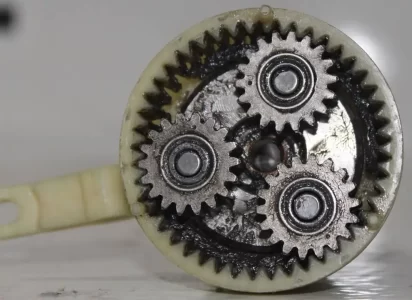

GDU is provided as a unit inside the starter motor where planetary gear set is used for torque multiplication. The GDU unit consists of three planetary gears, a ring gear and a sun gear.

Input is given to sun gear which helps in rotating planet gears which is guided with the help of the ring gear. Starter motor transmits the power to the pinion gear through the planetary carrier, which then the power is transmitted to the flywheel.

- For one rotation of the planetary carrier the sun gear has to rotate six times.

Cut Section View