Competitor teardown benchmarking is the process of studying our customer's product in comparison with their competitor's products to assess differences in features, architecture, BOM and should cost of all parts by tearing down the products to their last child parts.

Different aspects of benchmarking data captured by Advanced Structures India are meant for different usage inside your organization. Images shown on this page are either from our internal projects or are heavily edited to change numbers and specifics.

Feature Benchmarking

Before tearing down the vehicle, we map all its features on product level. During teardown, we map subsystem level features. This is later linked with corresponding BOM items used for providing the feature to get feature based cost benchmarkin.

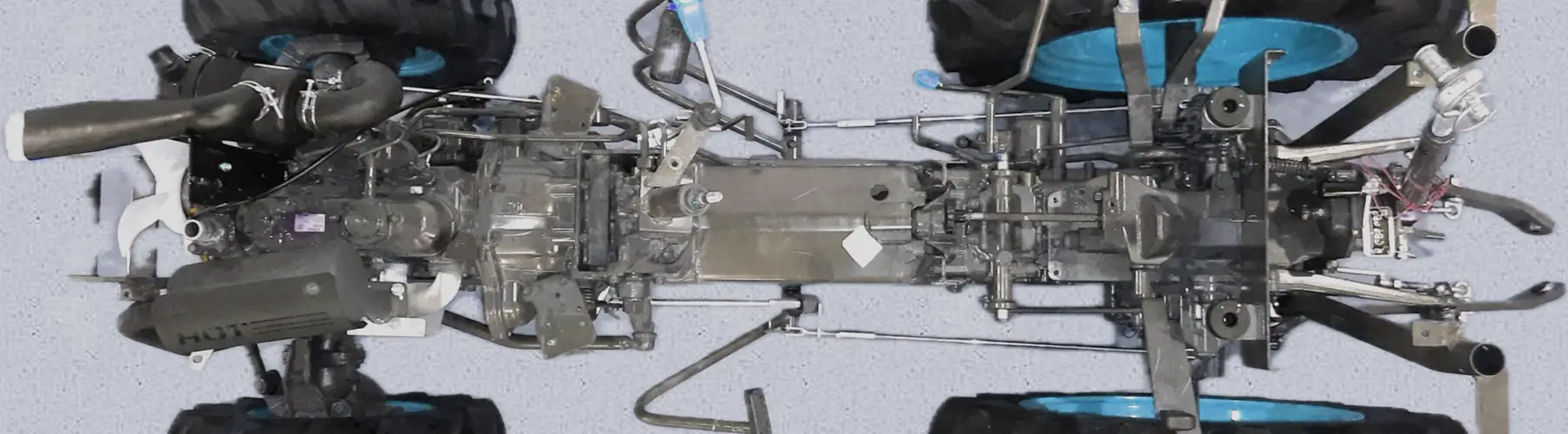

Architecture Benchmarking

After disassembling the vehicle, it's crucial to preserve the layout, packaging, and subsystem interactions. This is achieved by mapping and creating detailed diagrams that effectively illustrate the architecture. This method has proven to be superior for retaining architectural information when compared to 3D scan data.

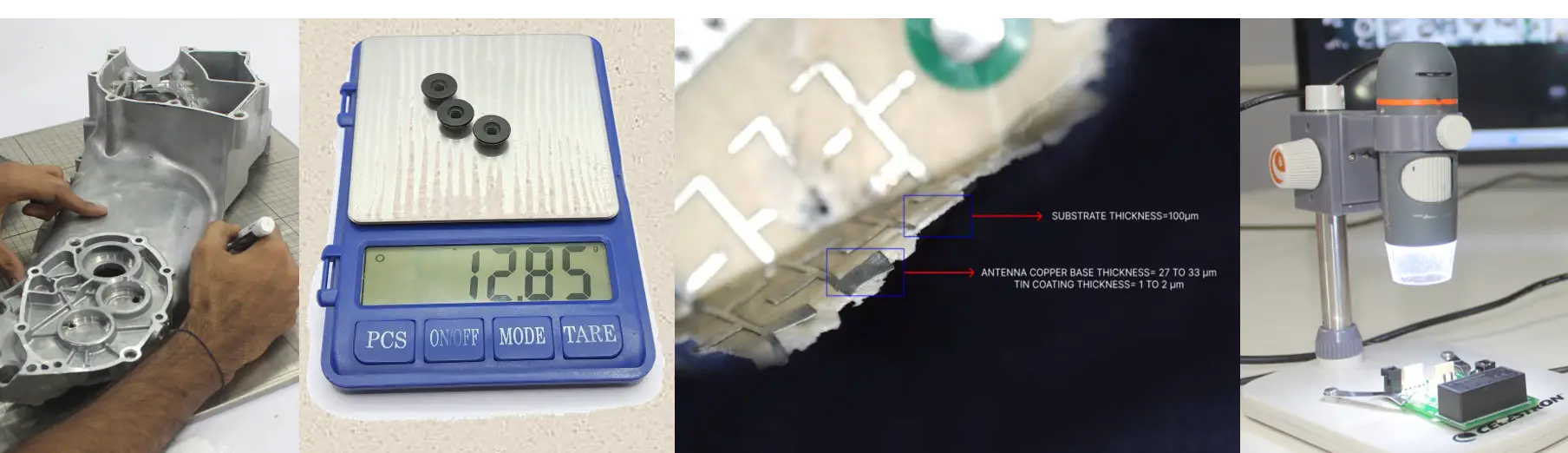

Part BOM Data Capture

In the detailed teardown process, we meticulously record over 50 parameters for each part, capturing all the necessary information to perform comprehensive should costing. The specific information captured per part may vary depending on the type of commodity.

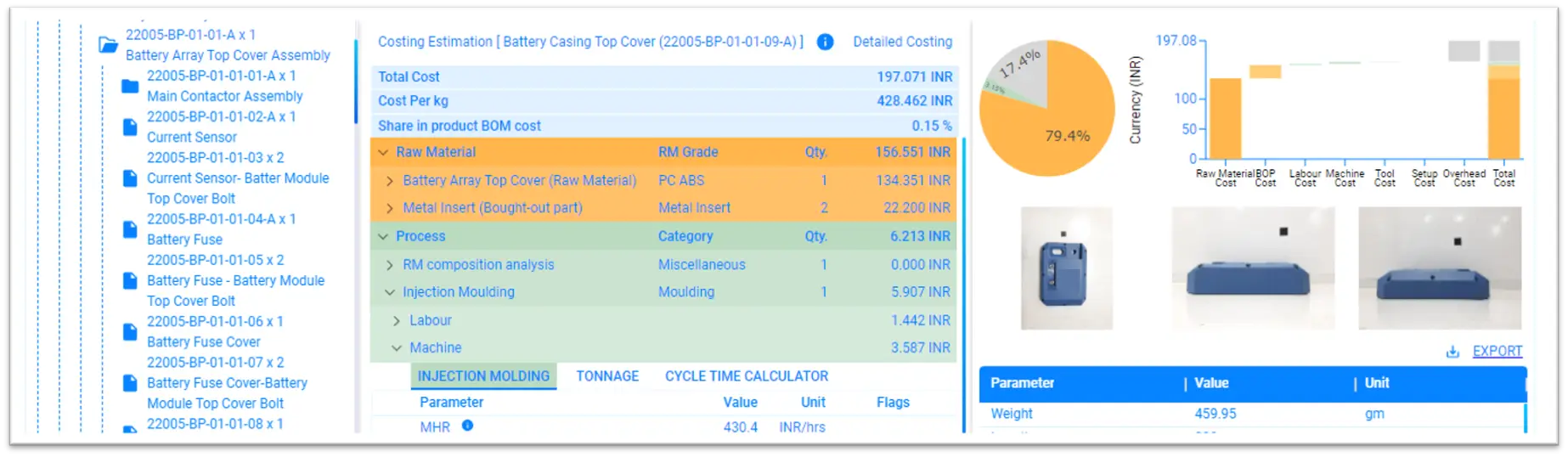

Should Costing

Following the measurement of all cost drivers for each part, we perform a thorough should costing analysis using xcPEP.