Digitize your Should Costing Operations

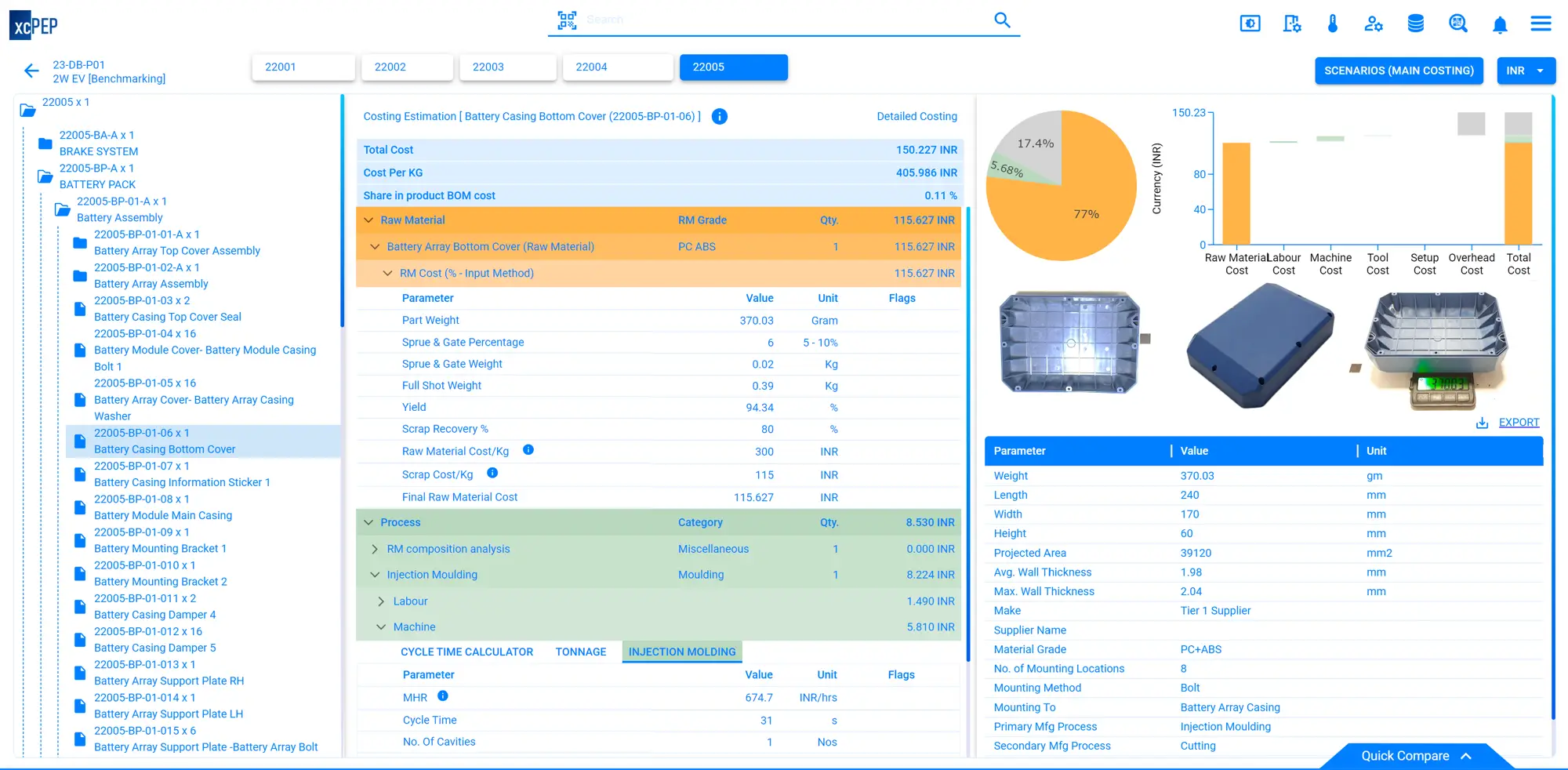

Using xcPEP, our customers bring their entire product portfolio, tooling, location specific labour and machine hour rates, suppliers and costing norms in a digital format. Should Costing of every part is done in extreme detail and effects of changing raw material rates, power rates, location specific changes etc are updated easily going forward.

Why use xcPEP for Should Costing?

xcPEP is a purpose-built should costing software platform for costing calculations, update and analysis in a multi-location, multi-currency, multi-product scenario. xcPEP vastly outperforms Excel and CAD based costing tools.

Excel fails at scale

-

Standardization in Should Costing: Excel's flexibility can lead to inconsistent templates, hindering cost analysis and decision-making in should costing.

-

Version Control & Updates of Should Cost models: Excel lacks robust version control, making it difficult to track changes and maintain accurate, up-to-date budgets.

-

Collaboration: Limited collaboration features in Excel can result in should costing data conflicts and miscommunication, essential for cross-functional teams in should costing.

-

Data Security: Excel may not provide sufficient data security, potentially compromising sensitive financial information contained in should costing.

-

Handling Large Datasets of Should Costing: Excel struggles with large datasets of thousands of parts, impacting performance and data analysis. Specialized software is more suitable for should costing.

- Designed for single user and general purpose calculations.

CAD based costing tools lack accuracy & transparency

- CAD-based should costing tools are primarily designed for designers, focusing on predicting manufacturing steps from CAD models.

- However, these tools prove inadequate for cost engineering teams due to their limited granularity when it comes to mapping manufacturing processes and inputs.

- Cost engineers require a higher degree of flexibility with in-depth analysis and real-time updates, especially considering factors like fluctuating raw material prices, evolving designs, various product configurations, different locations, and supplier options.

- Designed for design engineers and then ported to cost engineering teams.

Cost Engineers need

- Transparency: Detailed breakdown and visibility of all cost drivers and back up data for all values to enable evidence based discussion with all stakeholders.

-

Granular Process Mapping of Cost Drivers: The software should allow for detailed mapping of manufacturing processes, including accurate breakdowns of labour, material, and overhead costs.

-

Dynamic Updates to Should Cost Models: It should support real-time updates and analysis capabilities to adapt to changes in raw material prices, design revisions, product configurations, and supplier choices.

-

Standardization in Should Costing Norms: The tool must enforce standardized data entry and calculation methods to ensure consistency and accuracy in cost estimates.

- Automation in Should Costing Calculations: Automation of routine tasks, such as cost calculations and data updates, reduces manual work and enhances efficiency.

- Audit Trail in Should Cost of Parts: A feature for tracking changes and maintaining a detailed history of cost data modifications to ensure transparency and accountability.

- Designed for organization wide cost engineering function.

Who is xcPEP for?

You want precise, transparent and defensible should-costing for your entire direct purchase.

- You want to do it on a large scale and more detailed with high levels of automation but under your total control.

- You will use this Should Costing Output with other stakeholders for commercial decisions.

- You work in cost engineering, procurement or finance.

Who is it not for?

You want a software to automatically give rough cost estimate from CAD.

- You are a design engineer and need automated manufacturing process prediction from CAD file.

- You are fine with approximate values and are using it or design iterations.

- You will not be taking commercial decision on this cost.

xcPEP use cases we've seen at our customers

Digitization of cost engineering operations across teams and locations

Standardization of Should Costing models across organization

Automated raw material price indexing and rate adjustment with suppliers and customers

Quarterly RM wise, supplier wise, commodity wise, location wise variation analysis

Make vs Buy Scenario Costing

Manufacturing location wise scenario costing

New product should costing before virtual proto

Collaboration between cost engineering, purchase and finance teams on direct material spend

Deskilling and resource reduction in cost engineering

Linear Performance Pricing and many other analysis

Detailed audit trail of should costing updates

Got a problem to solve? Talk to us.

Actual customer quotes about xcPEP -

"xcPEP is transparent, every costing parameter is visible."

"It is easy to store images, videos, drawings along with costing data."

"Good access control for different stakeholders."

"Customizable checks prevent data entry errors."

"Shows all backing data to defend costing with internal stakeholders and suppliers."

FAQs about

Backed by Advanced Structures India

Migration

Migrating to xcPEP platform is fully managed and executed by ASI. All your products, their child parts, suppliers, material rates, costing norms and other considerations are configured by ASI during the deployment.

As a part of ongoing support, we provide consultation on development of new cost models for unforeseen new technology/commodity/location as and when required.

Information Security

xcPEP prioritizes information security with robust measures, including encryption, access controls, and regular audits, to safeguard sensitive financial data. ISO 27001 compliance ensures a high standard of information security, providing customers with confidence in the protection of their cost-related information.

Cost Engineering Capability

ASI has a decade-long track record of providing should costing services. Our experienced team is readily available to assist clients in enhancing their should costing models and facilitating large-scale updates, drawing upon our extensive expertise in the field.