Built for the Real World: A Modern Alternative to Legacy Should Costing Software

| Feature | Legacy Costing Software | xcPEP |

|---|---|---|

| Data Accuracy | Limited; databases often lack regional accuracy. | Real-world accuracy; uses detailed manufacturing logic and region-specific rates. |

| Transparency | Opaque "black-box" calculations; difficult to trace the source of calculated costs. | Full transparency; every assumption and calculation is visible, allowing users to drill down into cost drivers. |

| User Experience | Steep learning curve and heavy reliance on expert support. | Easy to use; modular approach reduces the need for large cost-engineering teams or consultants. |

| Cost of Ownership | High cost, high licensing fees, and complex implementation. | Lower total cost of ownership, typically one-third of legacy software. |

| Technology | Struggles with costing proprietary parts and PCBs; key process steps are missing. | Can cost proprietary parts and PCBs without needing detailed 3D models. |

| Data & Updates | Averaged out data which doesn’t precisely reflect actual costs in a region. | Specific researched data for every client, tailored to their regions of interest. |

| Application Speed | Slow. | Fast and responsive, built on the latest tech stack. |

| Architecture | Often on-site and complex. | Cloud-native design for faster performance and easier updates. |

| Cost Justification | Difficult to defend cost estimates due to lack of transparency. | Allows users to defend their estimates by making all calculations visible. |

Introduction

Manufacturers across automotive, off-highway, home appliance, electronics and machinery sectors have long relied on geometry-based costing software for should-costing and DFM analysis. However, many users have noted drawbacks. Common complaints include limited data accuracy, opaque “black-box” calculations, a steep learning curve, high complexity and cost, and heavy reliance on expert cost-engineering teams.

For example, reviewers have pointed out that the material cost databases of CAD-driven cost modeling platforms often lack regional accuracy, and that key manufacturing process steps (like certain castings or assemblies) are missing. Others lament that it’s “difficult to find the source and formula” behind calculated costs, and that using 2D drawings is “cumbersome” since the tool was built for 3D models. High licensing fees and the need for expensive customization are also often mentioned – one cost analyst described such parametric costing software as “expensive and [needing] expert service” to use. In short, users report that achieving accurate, defendable cost estimates with these geometry-based costing tools can be slow, resource-intensive, and opaque – especially when projects demand region-specific data or fast implementation.

Key pain points reported with Parametric Costing Software include:

Data accuracy and currency

Users wish geometry - based costing tools offered more up-to-date, location-specific material and labor rates. One engineer noted the tool’s database should better reflect “supplier market” costs to yield “closer to accurate/actual costing”.

Limitation in costing of Proprietary Parts and PCBs

When evaluating alternatives to CAD-centric costing platforms, a critical weakness often emerges: their reliance on readily available 3D models primarily limits its should-costing capabilities to internally designed components. This fundamental dependency means these tools frequently falters when tasked with costing proprietary parts—components with limited design data or supplied by third parties—and completely struggles with the complexities of PCB costing, where traditional 3D models are insufficient for accurate manufacturing cost analysis. This leaves a significant gap for companies needing comprehensive cost intelligence across their entire bill of materials, highlighting a major limitation of traditional parametric tools in real-world procurement and design-to-cost scenarios.

Transparency and traceability

The software has been described as a “black box”, where it’s “difficult to find the source and formula behind” calculated cycle times and costs. This lack of visibility makes it hard to defend estimates.

Ease of use and learning curve

Many users struggle with the interface and workflow of cad-based costing tools. For example, 2D modeling is “cumbersome,” and advanced customization requires deep expertise. One user explained that significant “competency is required to get into the details of parameters behind the cost model.”

Implementation complexity

Deploying a model-driven cost analysis system often demands large cost-engineering teams or consultants. Upgrades and custom integrations can be “painful” and require expert support.

Pricing and cost of ownership

The platform’s subscription and maintenance fees can be steep. Reviewers explicitly called out the “expensive” licensing and need for paid add-ons, forcing companies to build large business cases for approval.

Limited process coverage

Finally, some users find CAD-driven cost modeling platform offers incomplete process libraries. Reports mention missing capabilities for specialty parts (e.g. certain molds, fluids, assemblies) and an expanding machine database requirement.

In sum, feedback from forums and verified reviews shows that that this type of legacy costing software—while powerfull – can be overkill or too opaque for many teams. These issues have led engineers and sourcing managers to explore alternatives. xcPEP is one such next generation should costing software which has taken an entirely different approach from first principles.

How xcPEP Addresses Legacy Software's Pain Points

The xcPEP platform emphasizes real-world accuracy, full transparency, ease of use, and lower costs. In practice, this means:

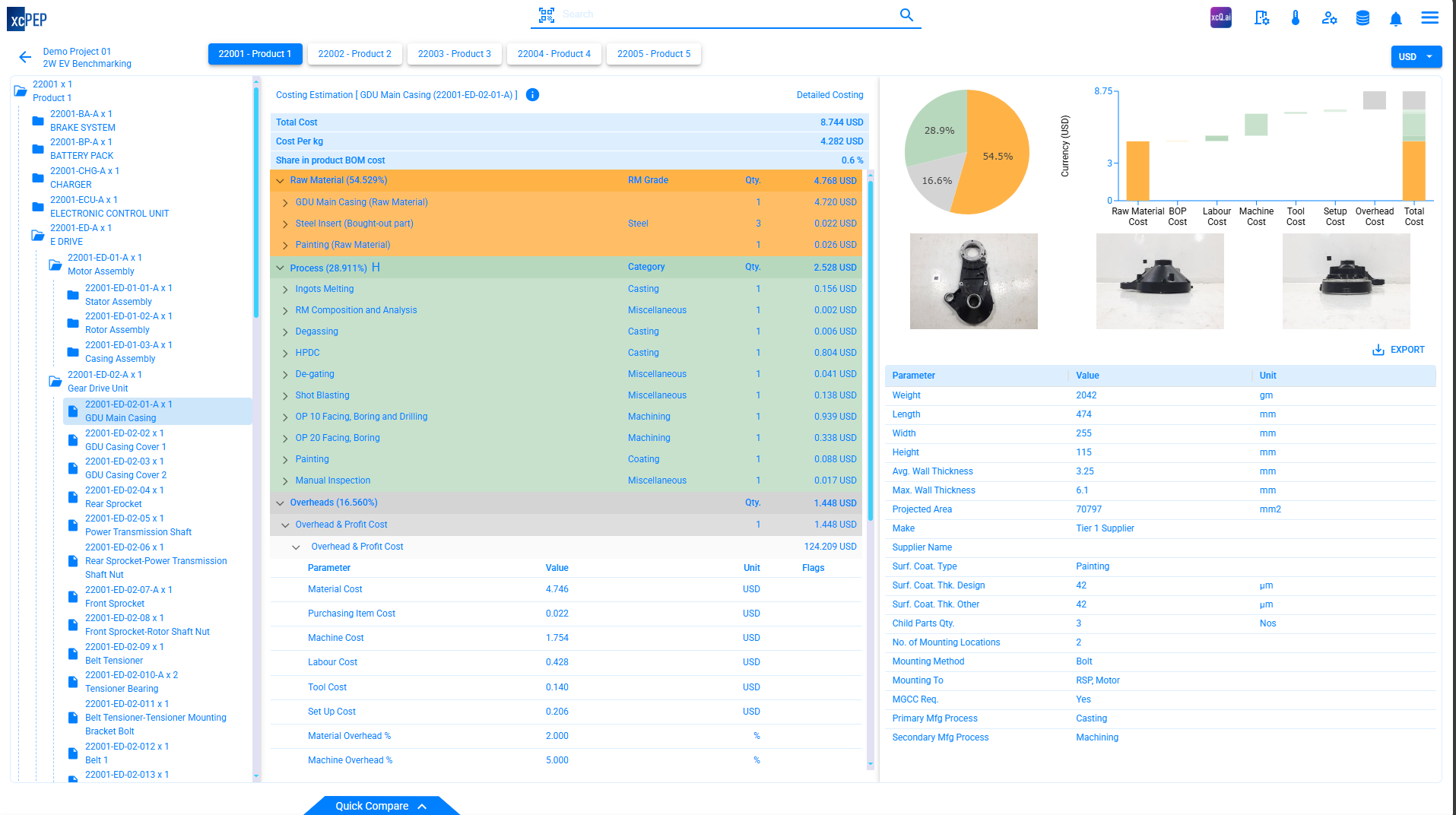

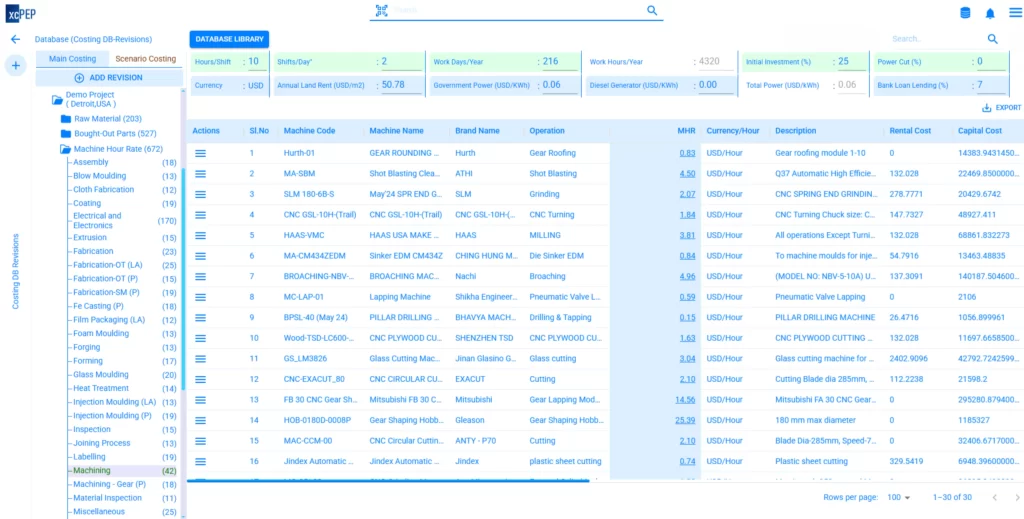

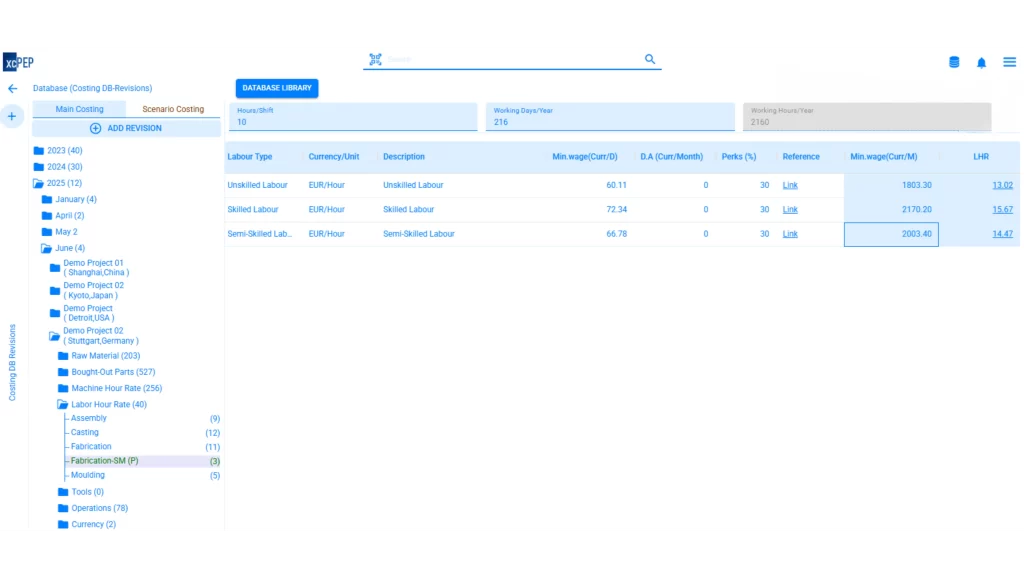

Real-world process accuracy

Unlike legacy parametric tools, xcPEP bases every cost model on detailed manufacturing logic and region-specific rates. As the vendor explains, “xcPEP reflects real, region and industry specific manufacturing practices for higher accuracy,” instead of relying on generic averages. In other words, material prices, labor costs and machine rates are kept up-to-date through the integrated xcPROC data hub, so estimates mirror current market conditions. This directly addresses concerns about outdated data – for example, one reviewer suggested that the data provided by parametric costing software's “can be improved with accuracy closer to the supplier market”. By contrast, xcPEP offers “verified” material and labor inputs, meaning costs are continuously refreshed and validated.

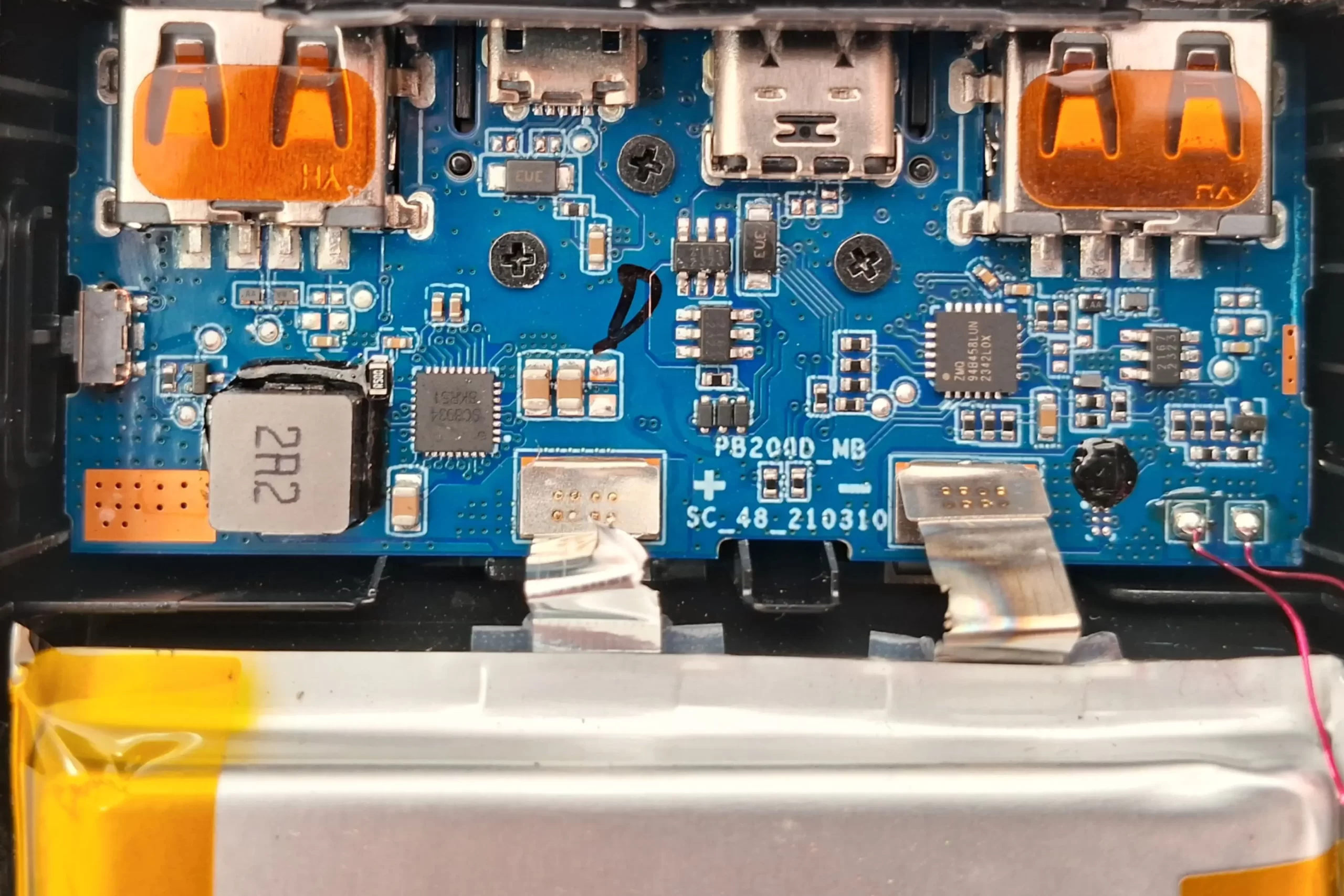

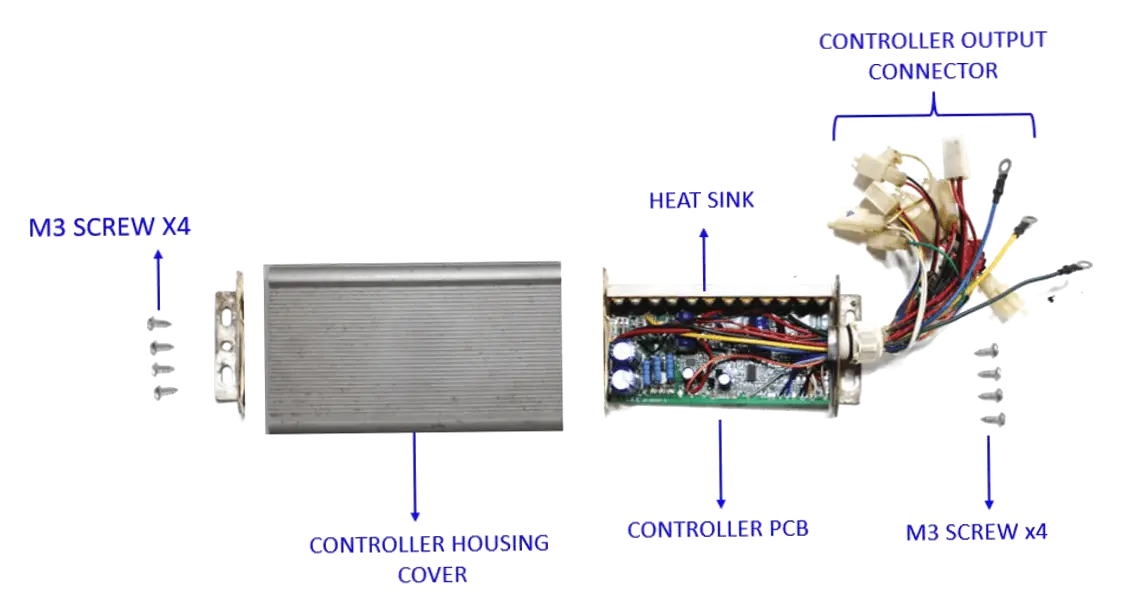

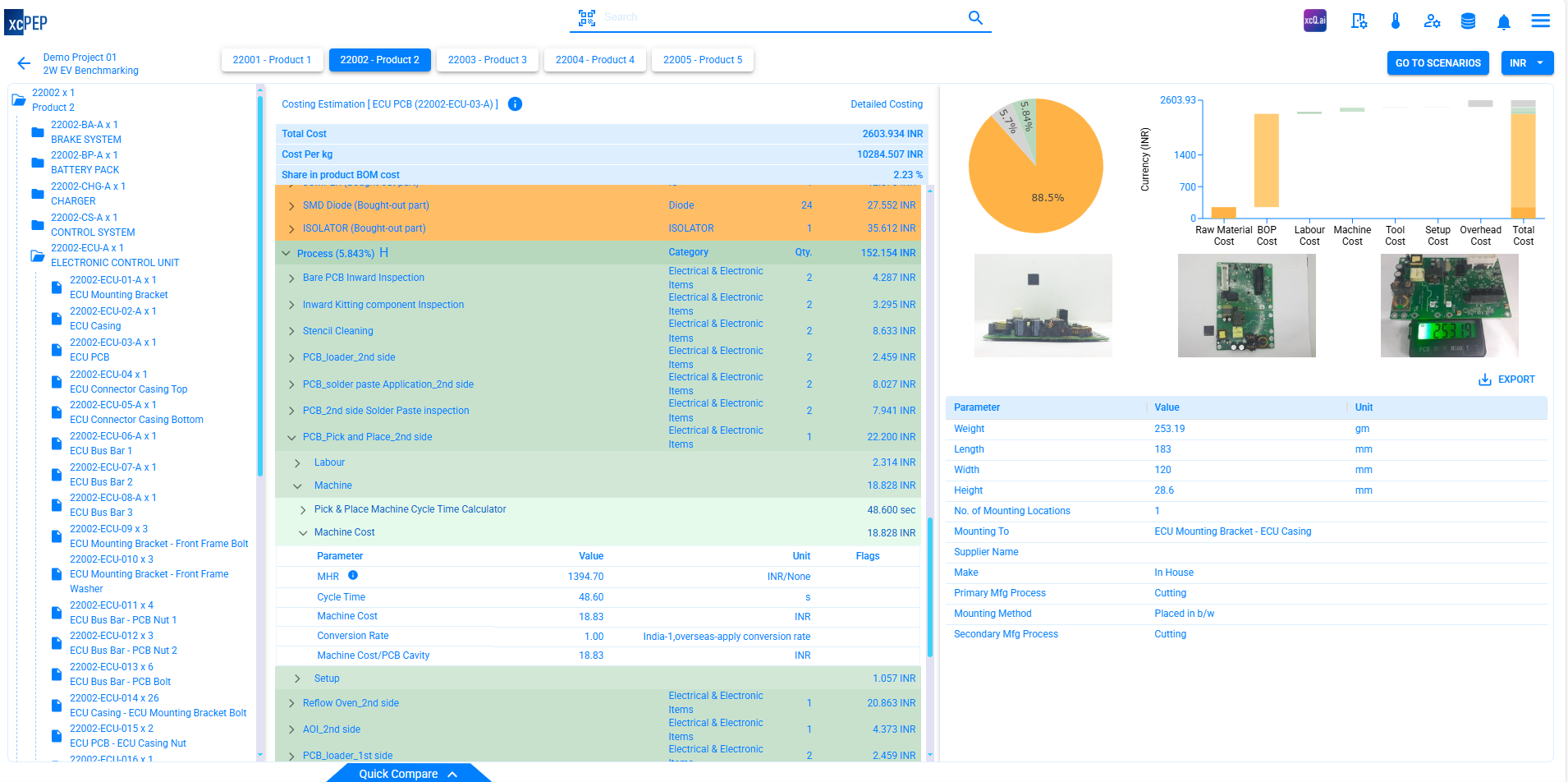

Comprehensive costing including electronics and proprietary parts

In contrast, xcPEP stands out as a robust alternative to traditional 3D model-based tools by directly addressing these critical should-costing challenges. Designed for unparalleled flexibility, xcPEP excels in proprietary part cost analysis, leveraging its deep manufacturing logic and extensive database to accurately estimate costs even without detailed 3D models from internal design teams. Furthermore, xcPEP offers specialized and accurate PCB costing capabilities, accounting for unique fabrication processes, material layers, and component placement, providing a complete and reliable cost breakdown. This comprehensive approach positions xcPEP as a superior solution for companies seeking holistic cost estimation and robust design-to-cost software that overcomes the inherent limitations of traditional tools.

The screenshot above shows the detailed costing of an electronic PCB as done in xcPEP, our should cost analysis software.

Full transparency and traceability

xcPEP eliminates the “black-box” issue by making every assumption and calculation visible. The platform is designed “with full transparency into calculations and inputs”, so cost engineers can drill down into each cost driver (materials, labor, overhead, etc.). As one xcPEP overview notes, the software “combines structure, transparency, and part-level traceability” to ensure every model is based on defensible assumptions. In practice this means if a manager asks “Why did cycle time jump?”, the user can trace exactly which parameter or formula changed, a feature lacking in many black-box cost estimation tools. This transparency aligns with user demands and directly addresses the common criticism that it’s “hard to understand the formulas” behind calculated costs.

The screenshot above shows how the xcPEP should costing software provides clear, transparent visibility into all cost details—allowing users to trace every number back to its source. The data shown here is for demonstration purposes only.

Intuitive cloud-native design

xcPEP is built from the ground up for the cloud, which enables much faster performance and easier updates. The site notes that “xcPEP is cloud-native and built for speed, even with complex assemblies”, addressing complaints that legacy desktop tools are slow or require heavy servers. The interface is also designed to be more user-friendly: a banner on the homepage proudly claims xcPEP has a “shorter learning curve” and is “intuitive and easy to adopt across teams”.

Advanced Structures points out that xcPEP is targeted at cost engineers and sourcing teams (not just designers), with straightforward workflows for common tasks. Training and ongoing updates are built into the SaaS offering, so organizations get new features and data automatically rather than enduring painful version upgrades as some legacy costing software admins have experienced.

Reduced dependence on large teams/consultants

xcPEP is modular and comes with built-in guidance, so companies don’t need to hire huge consulting teams just to get started. The vendor emphasizes “No need for consultants. xcPEP is modular and easy to tailor to your specific operations.” In practice, Advanced Structures even offers a “build-operate-transfer” service: their engineers help set up the system (configuring it to a client’s BOMs, data standards, etc.), then train the in-house team to run it. Within months, the customer is running a stand-alone cost lab with only minimal outside support. This model reduces the professional services burden that a geometry-based cost analysis platform often requires.

For example, one user noted that incorporating updates from these legacy costing software platforms is a bit of an exercise—an effort xcPEP seeks to eliminate through simpler modular updates and expert support. In short, xcPEP aims to let smaller teams achieve the same results: “xcPEP users get expert support from ‘ASI Engineering’ for model development... [so] everyone can work efficiently without needing large dedicated cost teams.”.

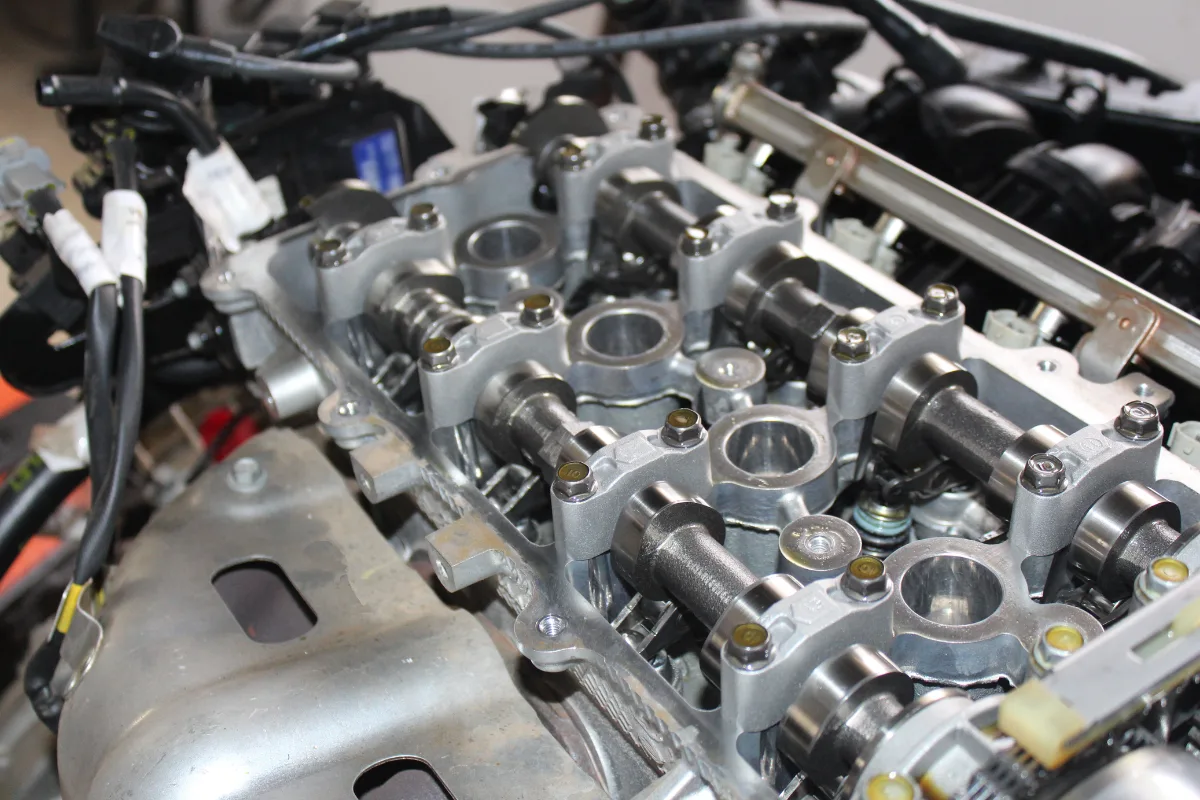

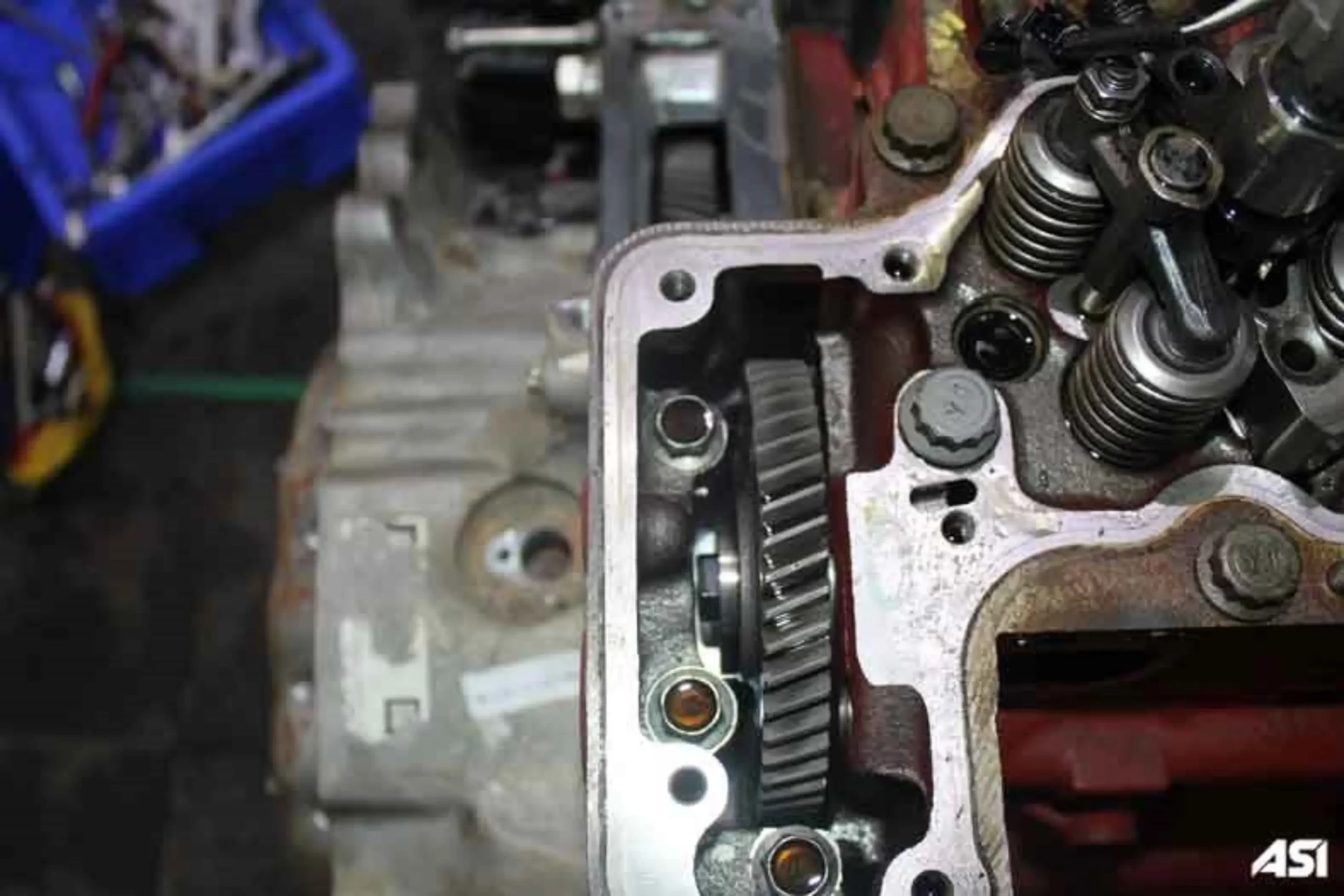

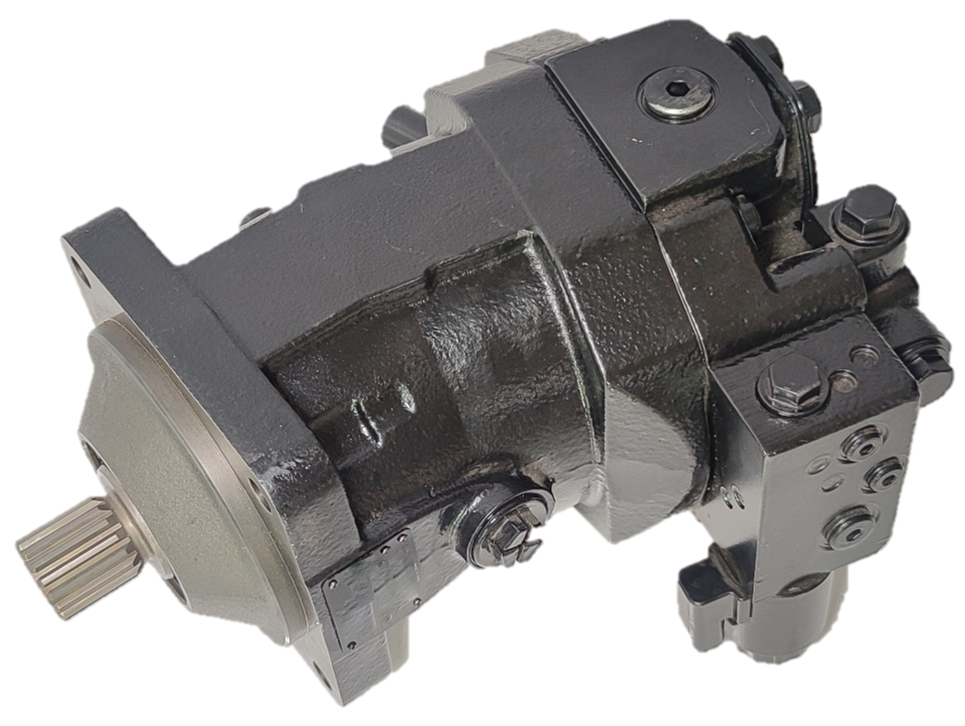

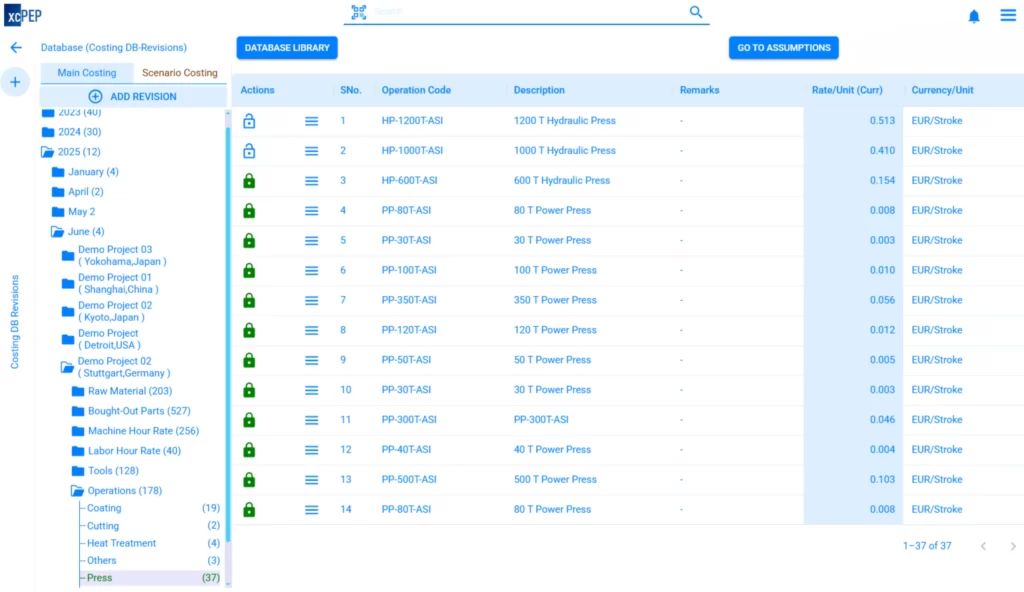

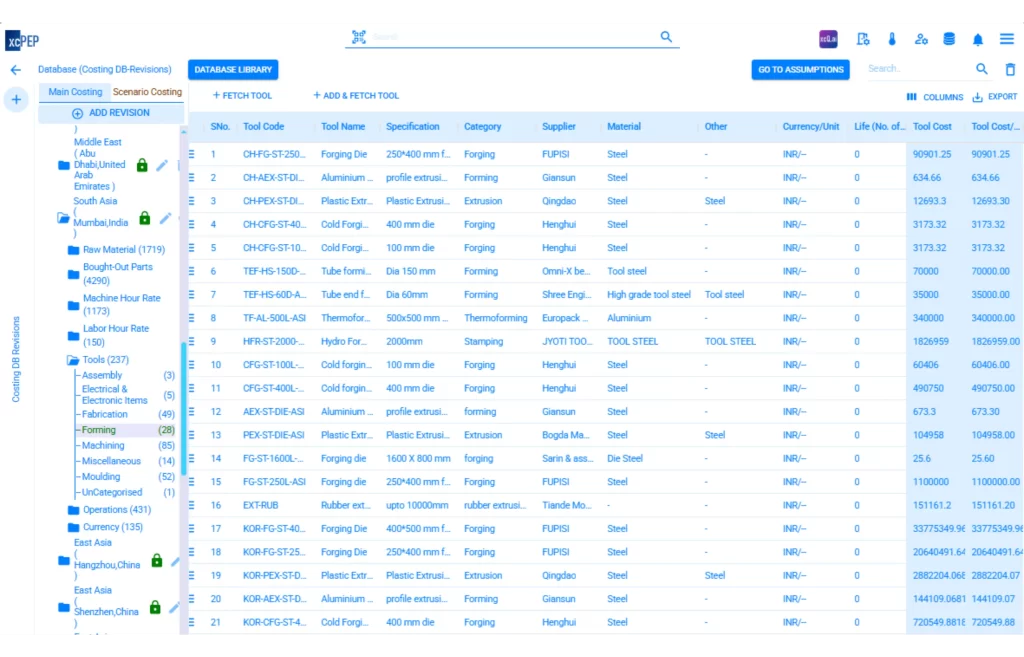

Comprehensive process and industry coverage

The xcPEP library includes a wide range of manufacturing processes across industries. Notably, it explicitly covers the sectors most hurt by legacy tools: automotive, off-highway, home appliances, and consumer electronics. As the website says, “xcPEP includes wide-ranging processes which cover every single type of part used in automotive, off highway, home appliances and consumer electronics.”.

This breadth ensures that niche parts (e.g. complex castings, electronics assemblies) can be modeled without workarounds – directly addressing user reports of missing process groups in parametric costing software. In short, xcPEP’s templates and calculators are designed to match real-world shop-floor practices in those industries.

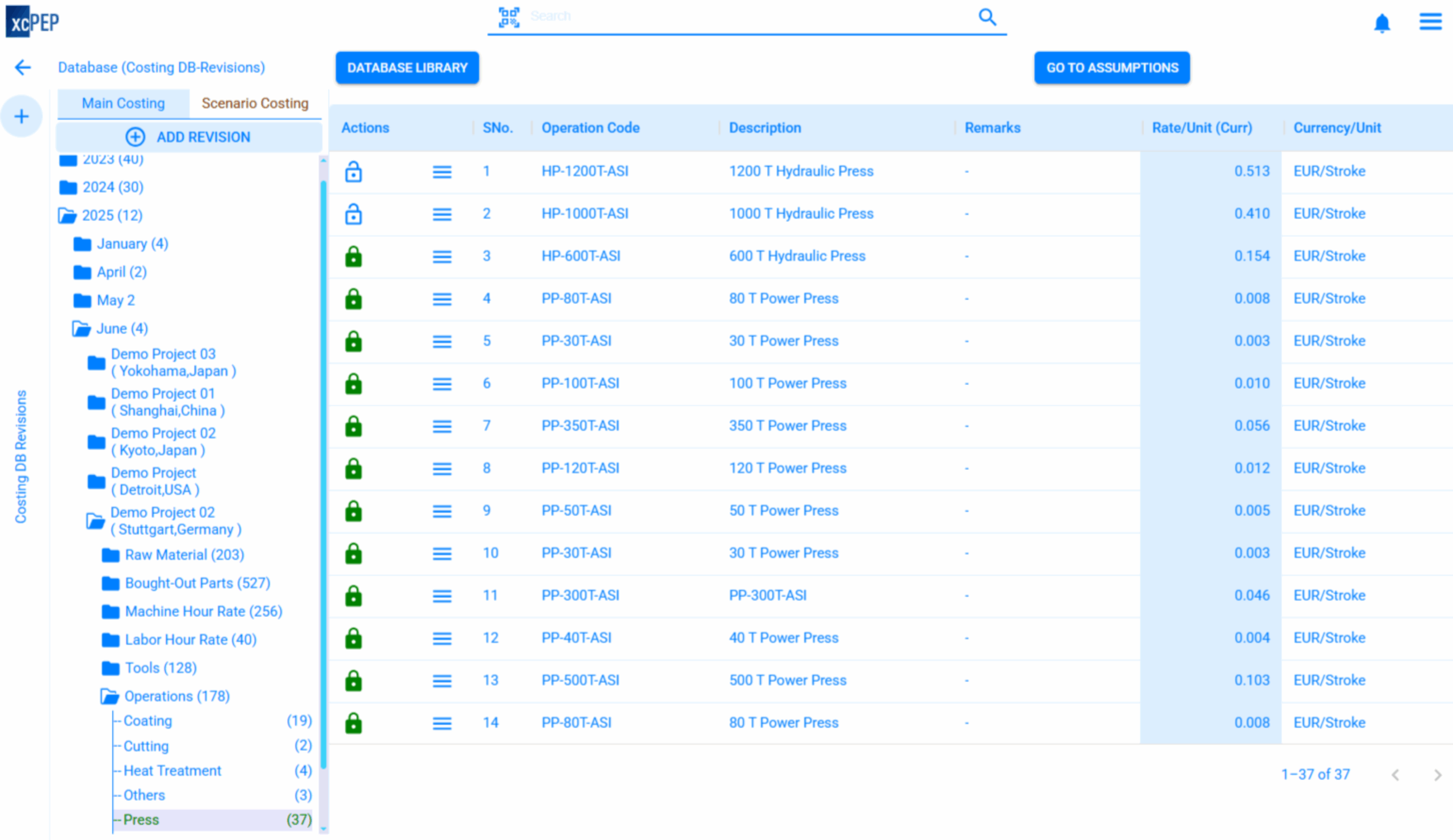

The screenshot above shows part of xcPEP’s operations database, including detailed machine rates for various press operations. The data shown is for demonstration purposes only. You can read more about our cost databases at xcPROC | Cost Data Platform.

Lower total cost of ownership

Finally, xcPEP’s modern SaaS approach translates into lower costs. The company claims a “one-third the cost of ownership” compared to legacy costing software. This is achieved through lean cloud architecture, automated updates, and minimal onsite infrastructure. In concrete terms, this means the subscription and support fees for xcPEP are much lower than the high annual costs that large-scale legacy costing software deployments often incur.

One reviewer noted that at his company “The annual subscription price [for a cad based costing tool] is not easy to digest”, implying that moving to a cheaper model is financially attractive. By cutting license and hardware costs by roughly two-thirds, xcPEP can fit smaller budgets while still delivering high-end capabilities.

Key benefits for users

Faster, more accurate cost targets for own & bought out parts

Switching to xcPEP enables teams to achieve reliable cost targets with less effort and overhead. The platform eliminates guesswork and accelerates should-cost workflows across departments.

Designed for key cost engineering use cases

xcPEP supports critical use cases like early design cost validation, supplier negotiation prep with detailed “fact packs,” competitor product benchmarking, and managing cost-reduction programs — all within a unified platform.

Transparent, data-driven negotiations

Every cost model in xcPEP is backed by data and logic. Sourcing teams can negotiate with greater clarity using detailed breakdowns that clearly explain each cost driver and assumption.

Defendable cost assumptions

Since every input is traceable, teams can confidently defend their cost targets during internal design reviews or external supplier meetings. There’s no black box — every number can be explained.

Easy to scale across teams

xcPEP’s flexibility allows even smaller OEMs and Tier suppliers to build and operate their own in-house cost labs — without the need for a large cost-engineering department or expensive IT support.

Solves real issues faced by legacy costing software users

xcPEP directly addresses challenges commonly reported in public reviews of parametric costing software, such as lack of transparency, difficulty in customizing models, steep training curves, and high ownership costs.

Up-to-date regional cost data

The platform uses current, localized manufacturing data — which means estimates reflect actual conditions and market rates, improving should-cost accuracy across global sourcing regions.

Transparent logic-driven models

Unlike black-box solutions, xcPEP gives users full visibility into how each cost is calculated. This builds trust across engineering, sourcing, and finance teams.

Cloud-native and IT-light

Being cloud-native, xcPEP avoids the heavy IT setup or maintenance required by traditional installed software. Teams can onboard faster and avoid delays caused by IT bottlenecks.

Fewer specialists needed

Because xcPEP is intuitive and supported by built-in expert logic, it requires fewer internal cost specialists to operate. Teams become self-sufficient faster and stay lean.

Lower licensing and operating costs

Customers report cutting licensing fees to nearly one-third of legacy platforms — while reducing the cost engineering headcount by up to 50%.

Built for modern cost engineering needs

For manufacturing teams tired of outdated and rigid costing tools, xcPEP offers a practical, modern alternative. It supports faster workflows, clearer insights, and a much lower total cost of ownership.

Ideal for complex, high-impact industries

xcPEP shines in industries where cost detail and traceability matter most — including automotive, off-highway, consumer electronics, appliances, and industrial equipment — making it a future-ready tool for serious cost engineering.

Difference in approach to automation in costing

Legacy parametric CAD based software prioritises CAD based automated black box costing for quick and inaccurate cost estimates.

By tailoring itself to your specific suppliers, locations, norms, and cost models, xcPEP creates a custom cost template that enables reliable and scalable cost estimation for future products.

Why automated costing alone falls short

In today’s global manufacturing environment, cost estimation is more complex than ever. Automated costing software promises speed and scale by analyzing 3D files or applying generic rules to derive manufacturing costs. Yet, this “one-size-fits-all” automation often fails to deliver accurate results. Why? Because real-world manufacturing processes vary widely depending on region, industry, manufacturer capabilities, quality standards, raw material availability, and supplier networks.

The pitfalls of pure black box automation in costing

Automated costing engines that rely exclusively on CAD or preset formulas often gloss over these nuances, resulting in “black box” outputs that lack transparency and real-world accuracy. Companies using such models may find themselves negotiating or planning based on faulty data, impacting profitability and supplier relationships.

- A machining process in Germany with strict quality norms, high labor costs, and premium materials differs vastly from one in Southeast Asia.

- Electrical component sourcing and assembly methods vary from one industry vertical to another, depending on technology maturity and supplier base.

- Raw material availability can modify manufacturing processes across the world for achieving the same outcome.

5% error in cost calculation leads to 50% error on EBIDTA level.

xcPEP’s Solution: Deep adapation and templatisation for each customer for real-world accuracy

At Advanced Structures India (ASI), we believe the answer lies in blending automation with collaborative customization. Instead of solely depending on automated algorithms, xcPEP’s approach focuses on working closely with each customer to build customer-specific cost templates.

Deep adaptation for every customer

Development of templatized cost models

Reusable, extensible templates

Transparent, traceable costing

Benefits of templatization-enabled automation

- Higher Accuracy: Cost estimates mirror your specific manufacturing environment and supply chain realities.

- Flexibility and Control: Easily adapt templates as suppliers change, materials fluctuate, or production methods evolve.

- Speed and Scalability: Once tailored, costing becomes a rapid exercise—scalable across teams and part families.

- Better Negotiation Power: Transparent, defendable cost breakdowns lead to more effective supplier discussions.

Our Products

Purpose-built for real world, transparent, and scalable should-costing.

Explore xcPEP, our cloud-native should-costing software, and xcPROC, our structured cost database for accurate and scalable should-costing.

xcPEP

xcPROC

Industries Powered by xcPEP

Real-World Cost Engineering Across Key Sectors

xcPEP supports should-costing across complex industries with detailed, process-specific models. It adapts to how each part is actually manufactured—not how a legacy tool thinks it should be.

Our Clientele

Cost Databases

Product Studies

Our engineers regularly undertake internal projects on products of interest. These initiatives help enhance our solutions for specific product categories and also generate demo data for customers to evaluate. Below are blogs showcasing the outcomes of these studies.

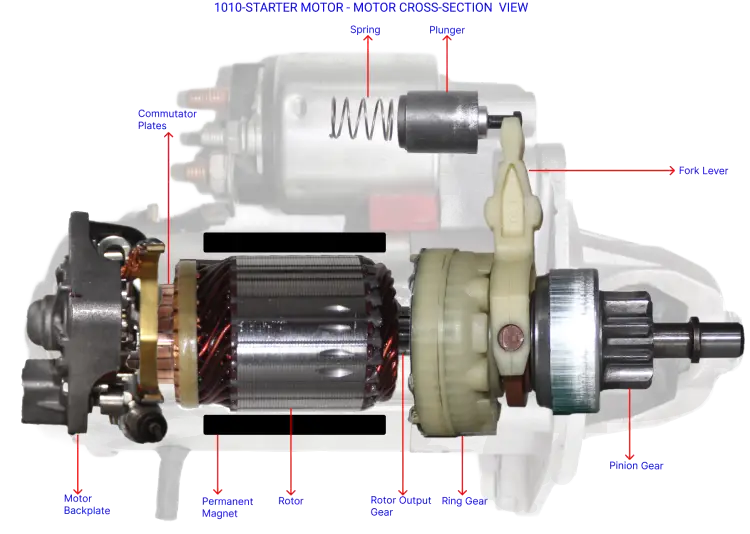

Automotive & Off - Highway Product Studies

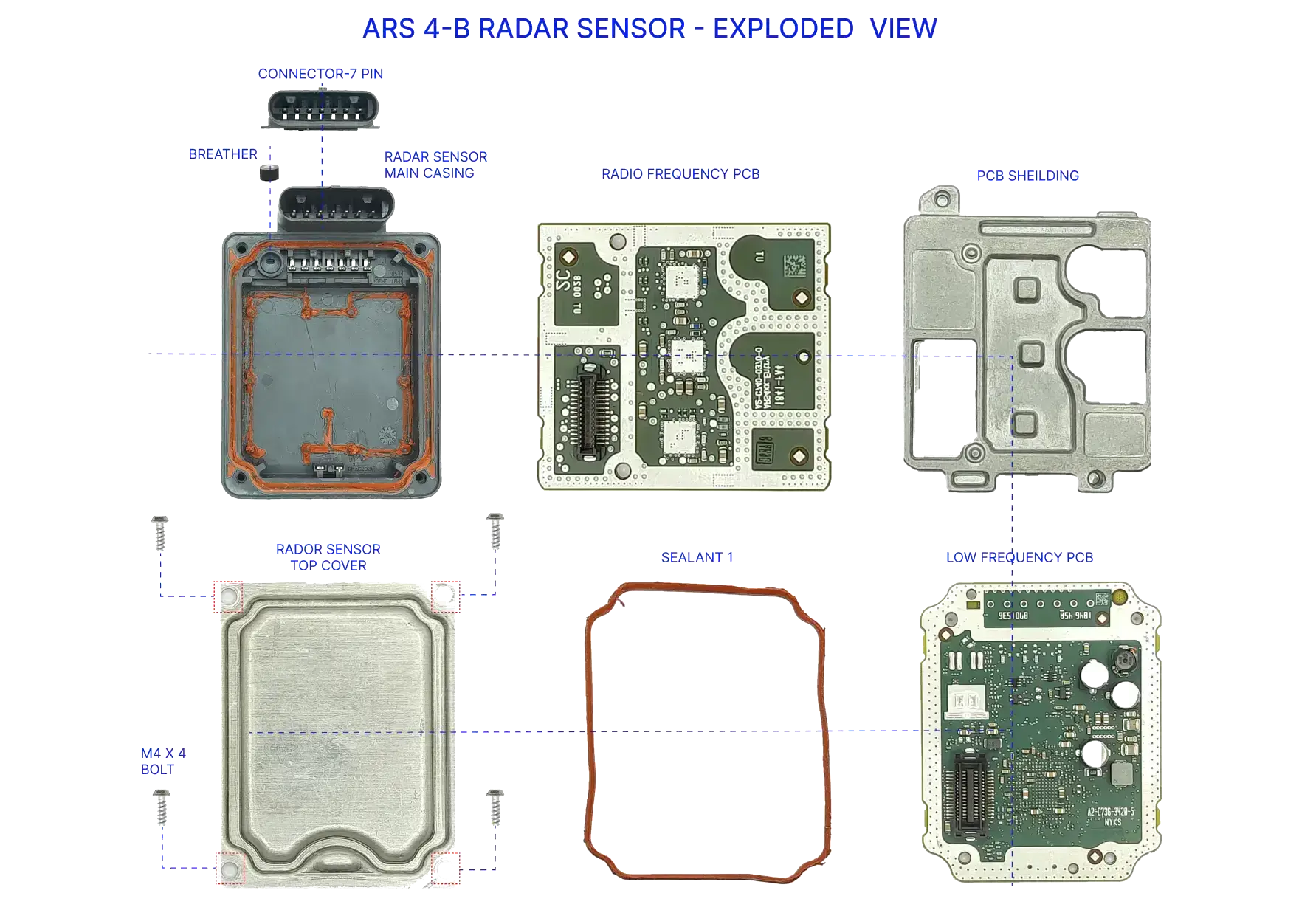

Consumer Electronics Product Studies

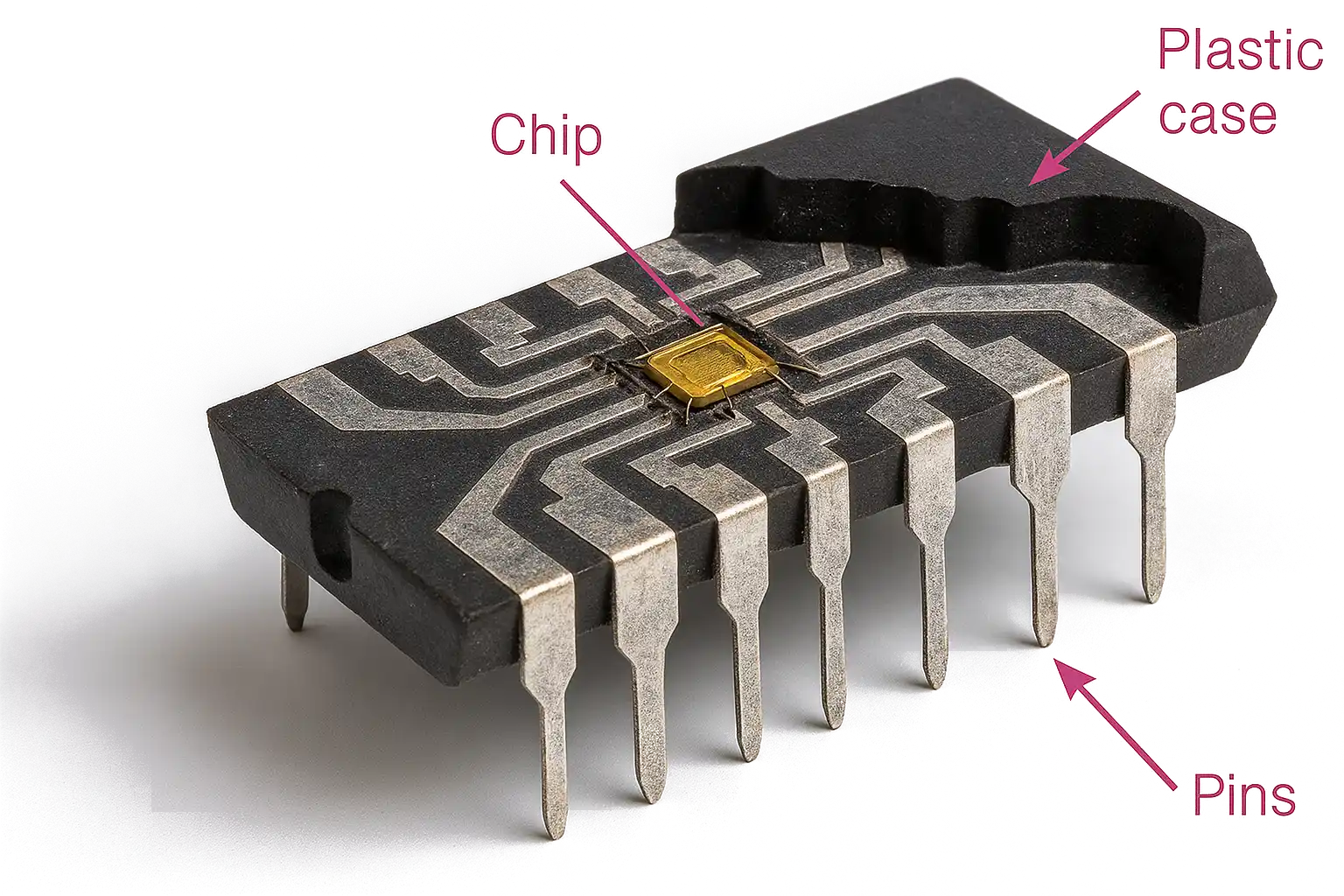

How to do Should Costing of Semiconductor Packaging?

In this blog, we focus on the semiconductor packaging stage inside an IC. We should-costed the entire process - from die singulation and lead frame prep to bonding, molding, testin

Omron BP Monitoring Device HEM-7120 Teardown, BOM and Should Costing

Detailed teardown and Bill of Materials (BOM) analysis of the Omron HEM-7120 digital blood pressure monitor. Understand manufacturing costs and product design insights.

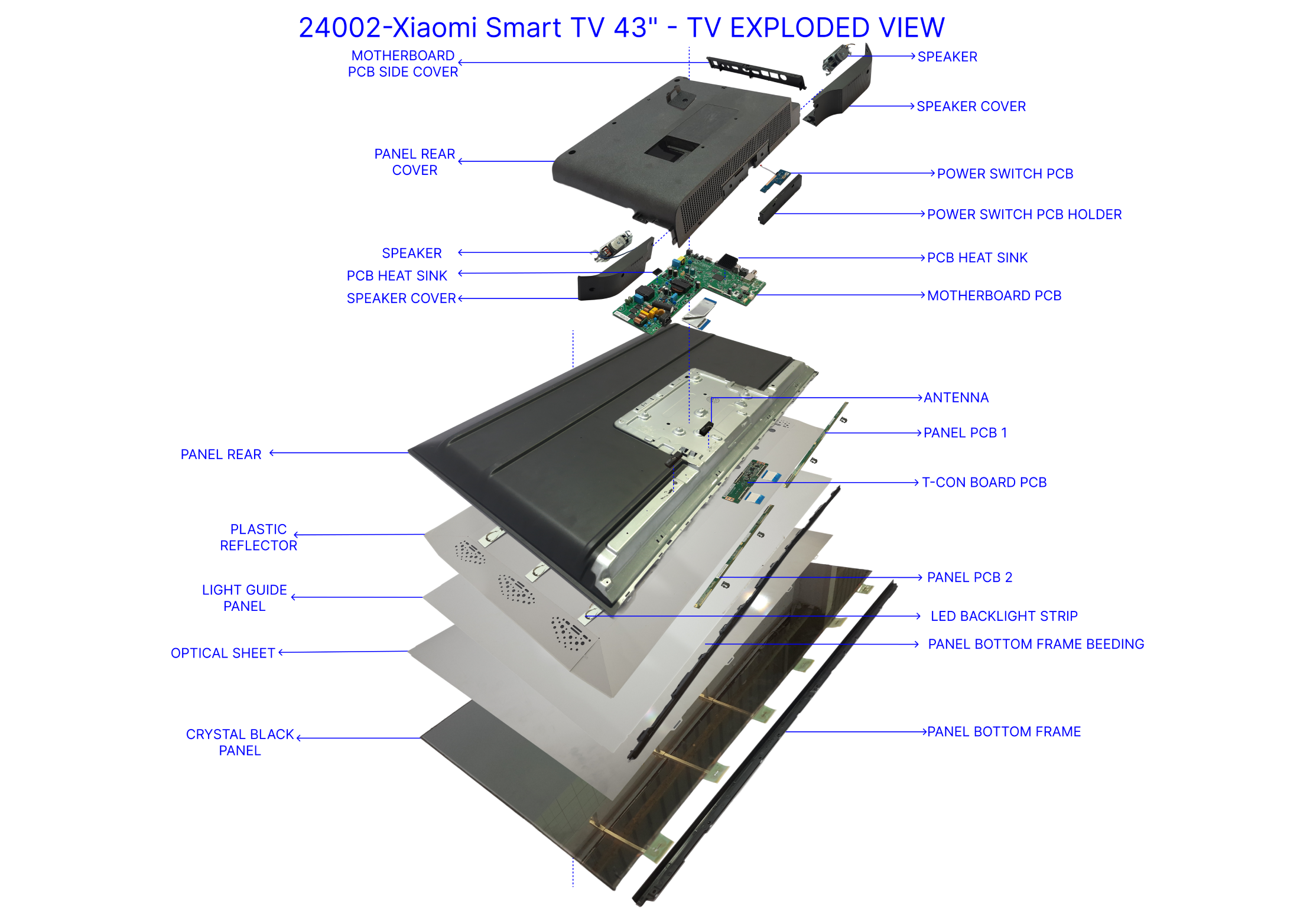

Xiaomi Smart LED TV 43” Teardown, BOM and Should Costing

Detailed teardown and BOM analysis of Smart TV 43. Explore LED TV component costs, and manufacturing insights.

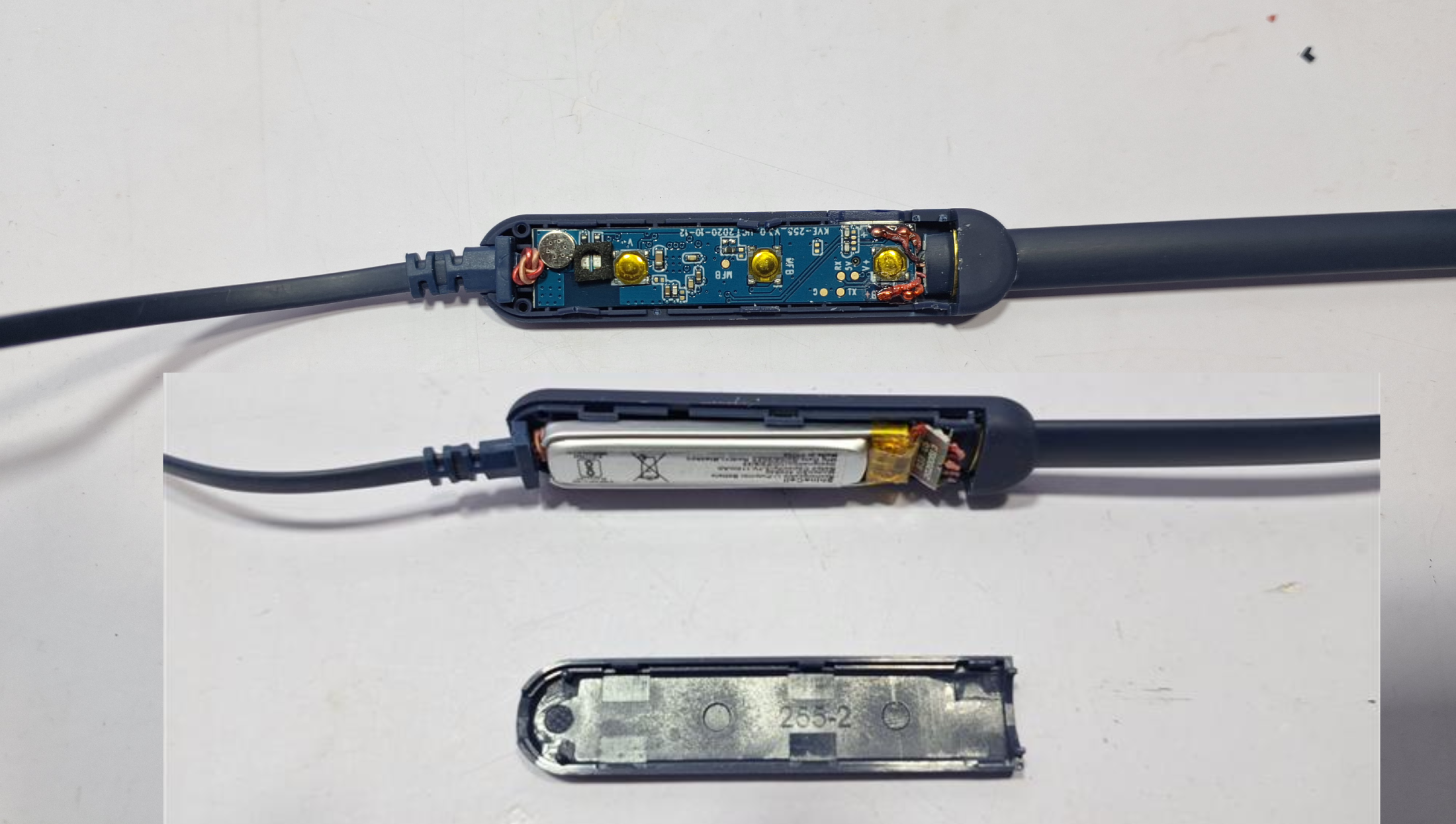

Bluetooth Earphone Teardown, BOM and Costing

We have conducted a detailed teardown of a bluetooth neckband headphone, mapped its bill of material and calculated its should cost.

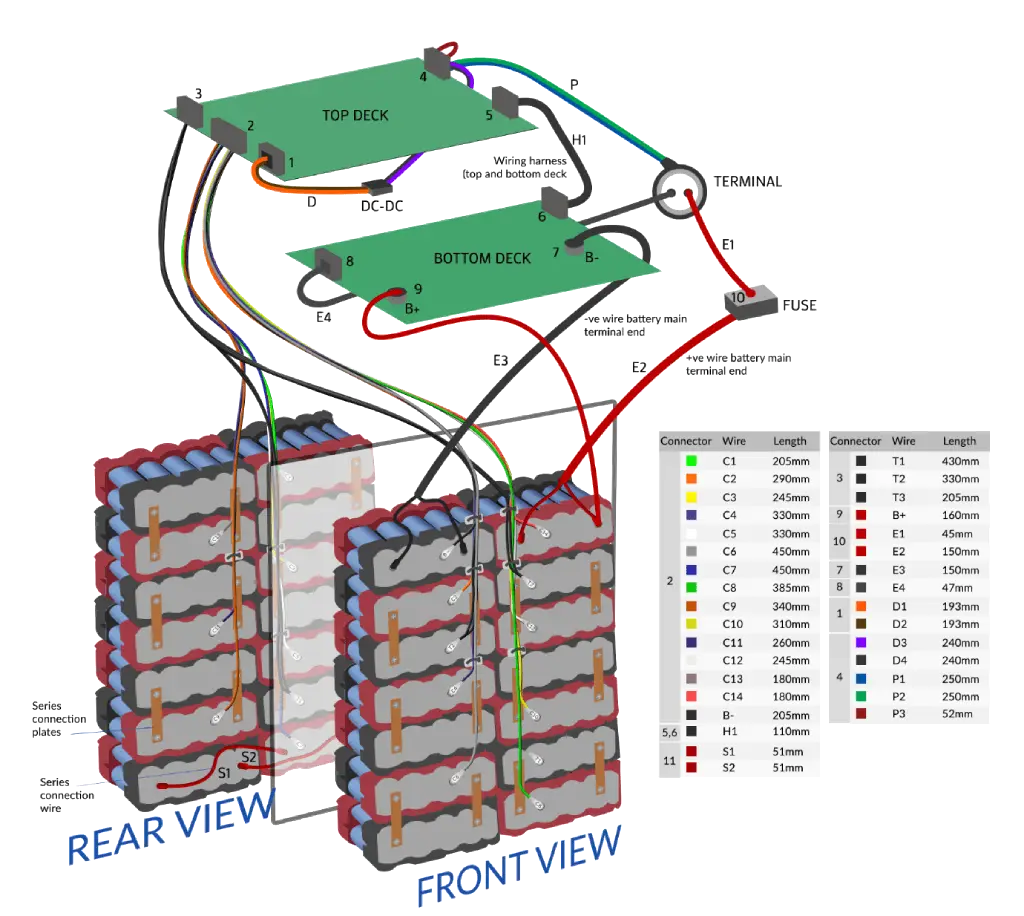

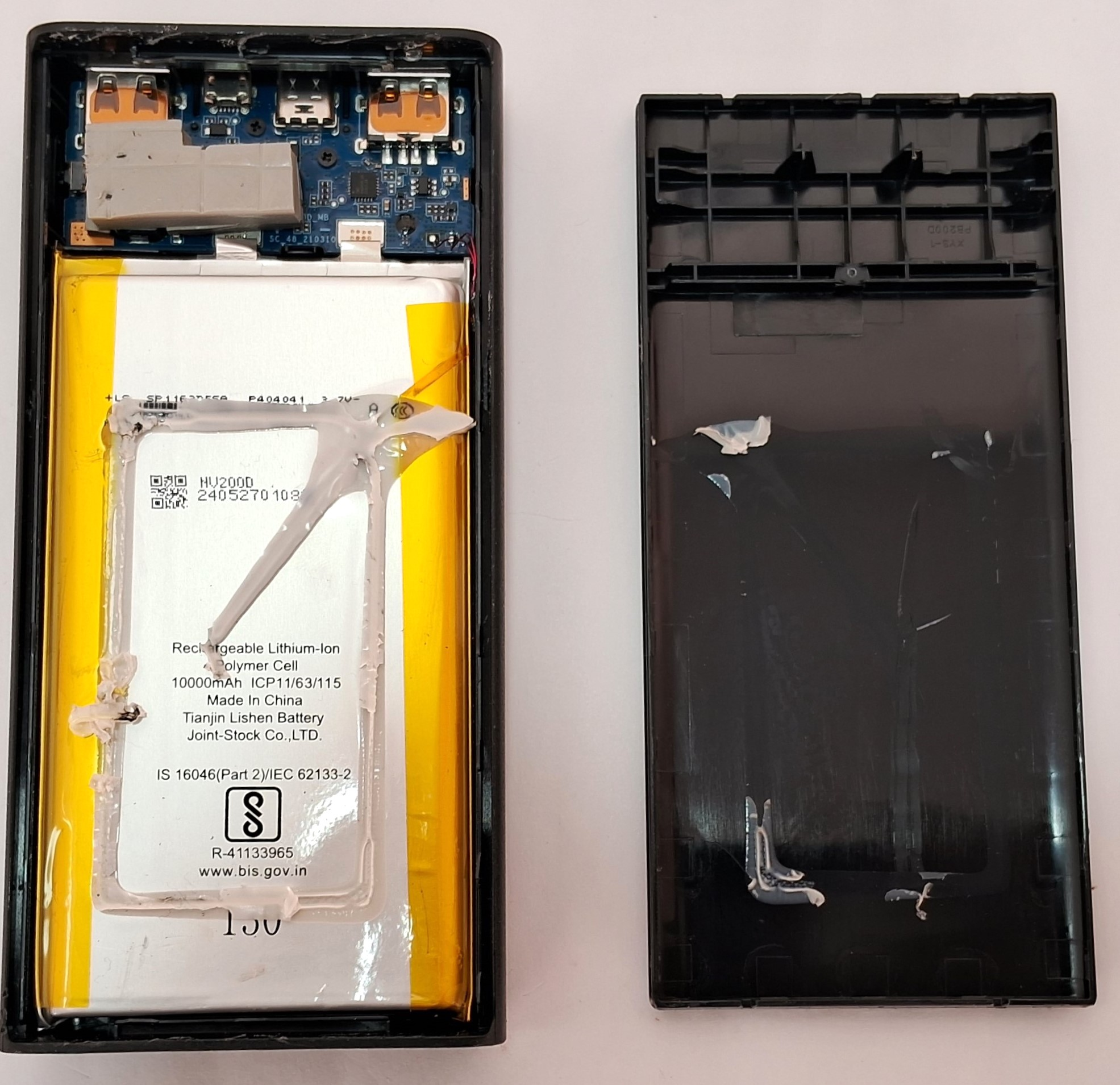

Mi PowerBank 3i Teardown and Costing

We have conducted a detailed teardown of a power bank, mapped its bill of material and calculated its should cost.

PCB Teardown Benchmarking & Cost Reduction Insights

This is a blog about benchmarking features, BOM and architecture of an automotive PCB. This also includes study of all direct costs of the PCB by zero based costing method.

DJI Inspire 1 Drone Teardown and Costing

We benchmarked a DJI Inspire 1 drone to study its design and direct cost. This study also included a detailed zero-based costing exercise of all the drone components.