Refrigerator Should-Costing & Teardown Analysis with xcPEP

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publication.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

Explore xcPROC →Introduction to Refrigerator Should Costing & Teardown Study

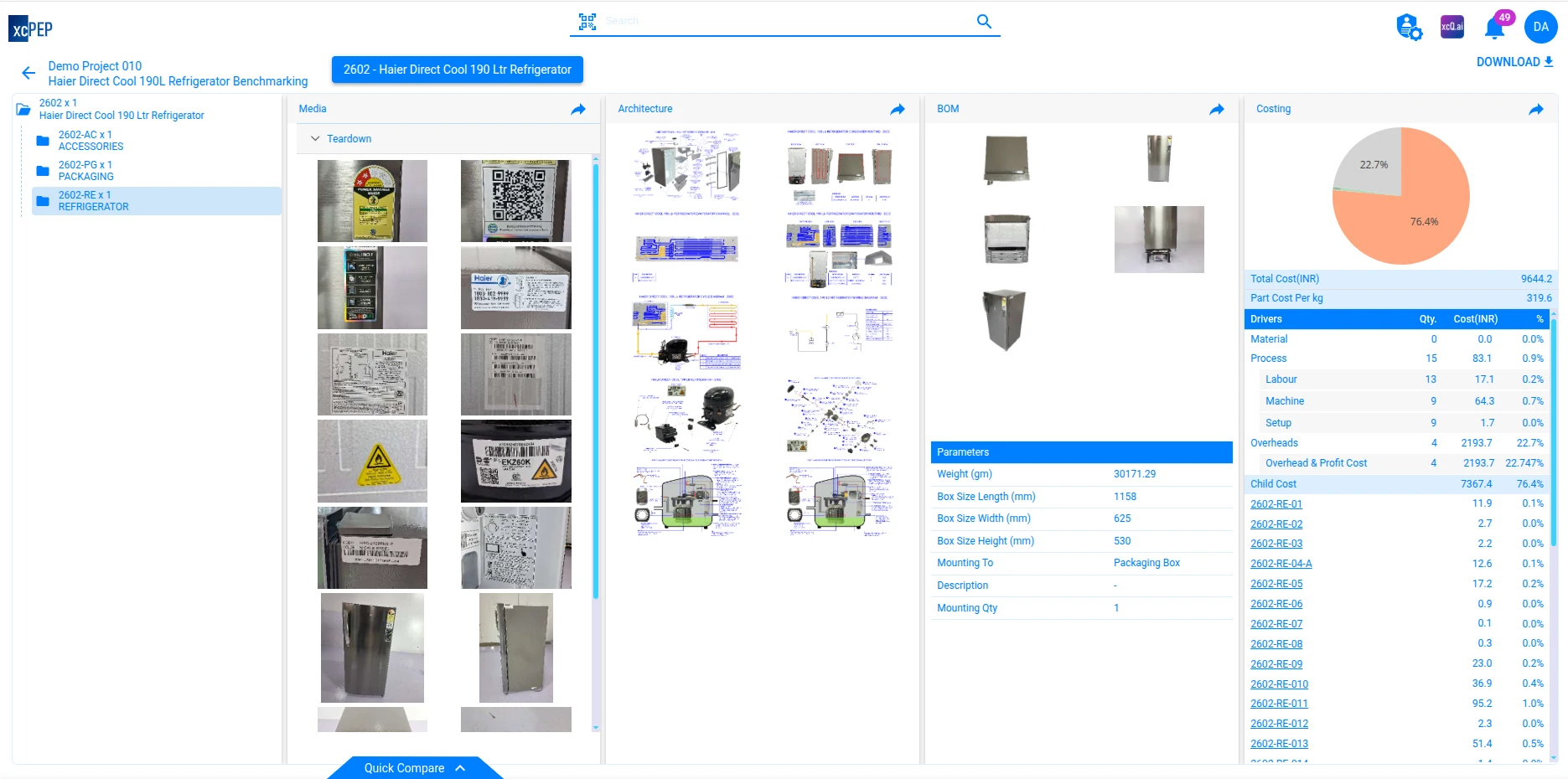

Refrigerators are among the most widely produced and cost-sensitive appliances, making cost transparency essential for manufacturers and procurement teams worldwide. This study presents a teardown and refrigerator should-costing analysis of a Haier Direct Cool 190 Ltr (2-Star) single-door model, carried out by ASI Engineering with xcPEP to evaluate its design, materials, and manufacturing economics.

This teardown is conducted from a functional and component-level perspective to estimate the Bill of Materials (BOM) and uncover the cost distribution across key subsystems.

Features & Specifications of Direct Cool Refrigerator

Below is a detailed breakdown of its design, performance, energy usage, and functional

specifications:

Direct Cool Technology

Refrigerator Compressor

The EKZ60K is a fixed-speed reciprocating compressor operating on a 220–240V, 50 Hz single-phase supply. It uses R600a(Isobutane) refrigerant and has a Locked Rotor Amps (LRA) rating of 7.1A. Its approximate cooling capacity is 600–700 BTU/h, ideal for small direct cool refrigerators.

Refrigerator Capacity

The refrigerator has a total capacity of 190 litres, organized into several compartments. It features a 14-litre freezer with Diamond Edge Technology for efficient ice formation and an 11.5-litre vegetable case covered with a lid measuring 415 x 235 mm for moisture retention. The main chamber includes two toughened glass shelves, each with a surface area of approximately 145,000 mm², and four door shelves for bottles and condiments. Additionally, it has a chiller tray with a maximum area of 428 x 338 mm.

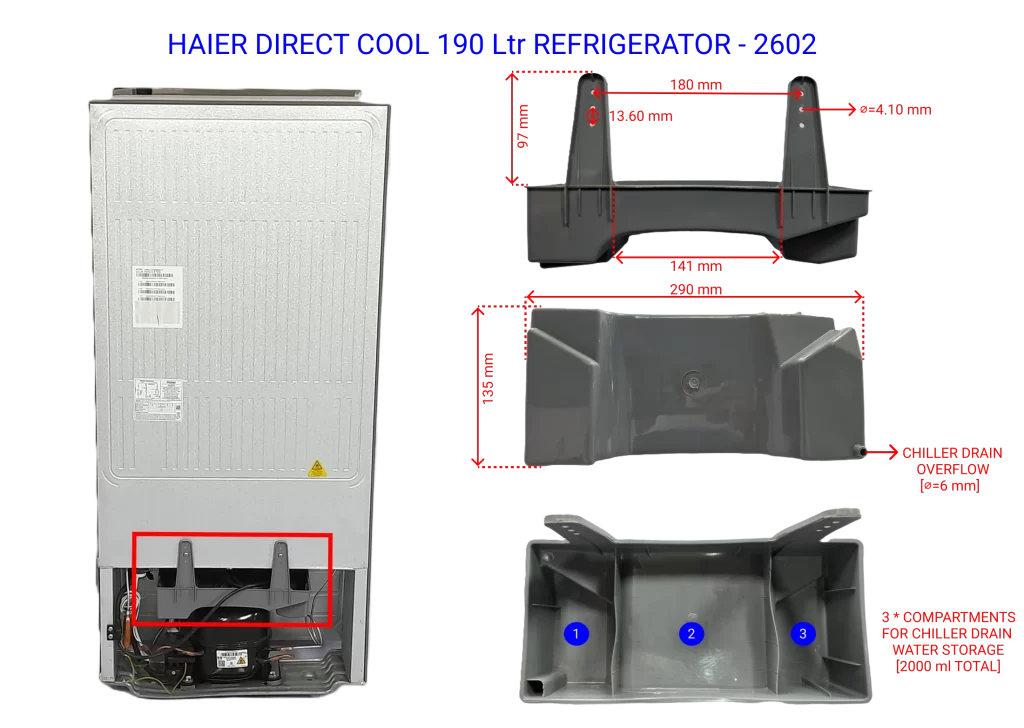

Defrosted ice water collector

The refrigerator also includes a defrost water collection system to prevent water accumulation inside the cabinet. When manual defrosting is performed, the melted ice flows down to the chiller tray, passes through a drain funnel, and is finally collected in a 3-litre water collector located at the rear.

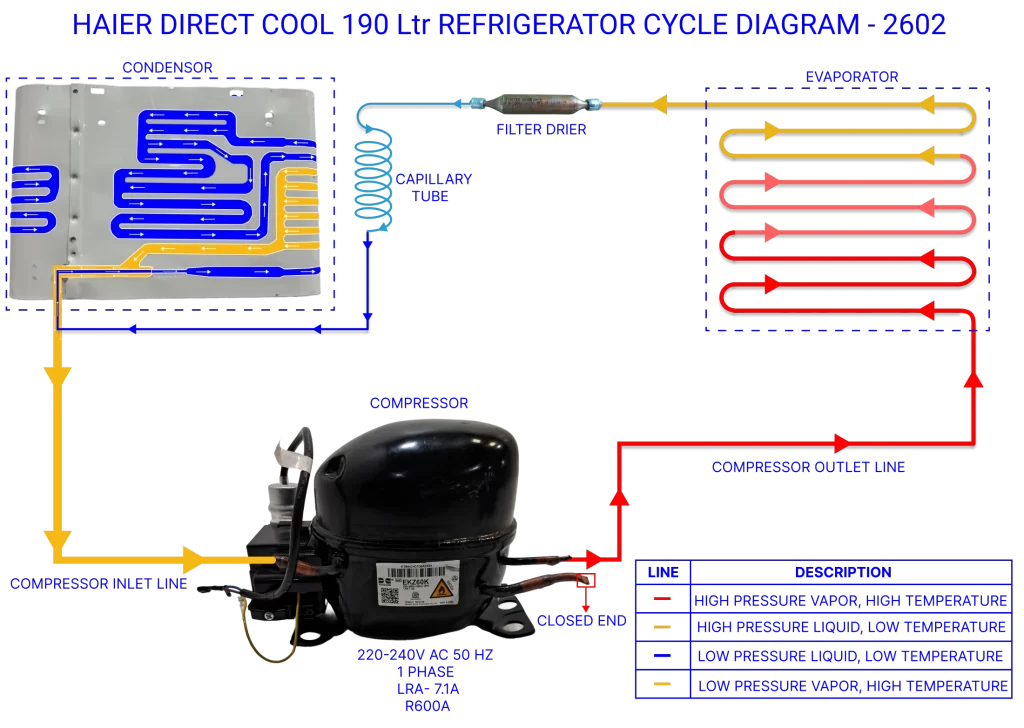

Working of Refrigerator: Cooling Cycle Explained

1. Power Supply

2. Door Switch Operation

- If the refrigerator door is open, the door switch closes, turning on the lamp to illuminate the compartment.

- If the door is closed, the door switch opens and the lamp turns off.

3. Thermostat Operation

The thermostat monitors the internal temperature and remains open when cooling is not needed, preventing power from reaching the compressor.

4. Relay and Start Capacitor

- When the internal temperature rises above the set point, the thermostat closes, allowing power to flow to the compressor circuit.

- The relay is energized and temporarily connects the start winding and capacitor to assist in starting the compressor motor.

- The start capacitor provides a phase shift, helping the compressor motor generate enough torque to start.

- Once the motor reaches sufficient speed, the relay automatically disconnects the start winding, and the compressor continues to run on the main winding.

5. Refrigerant Compression

The compressor compresses low-pressure refrigerant gas from the evaporator into high-pressure, high-temperature gas.

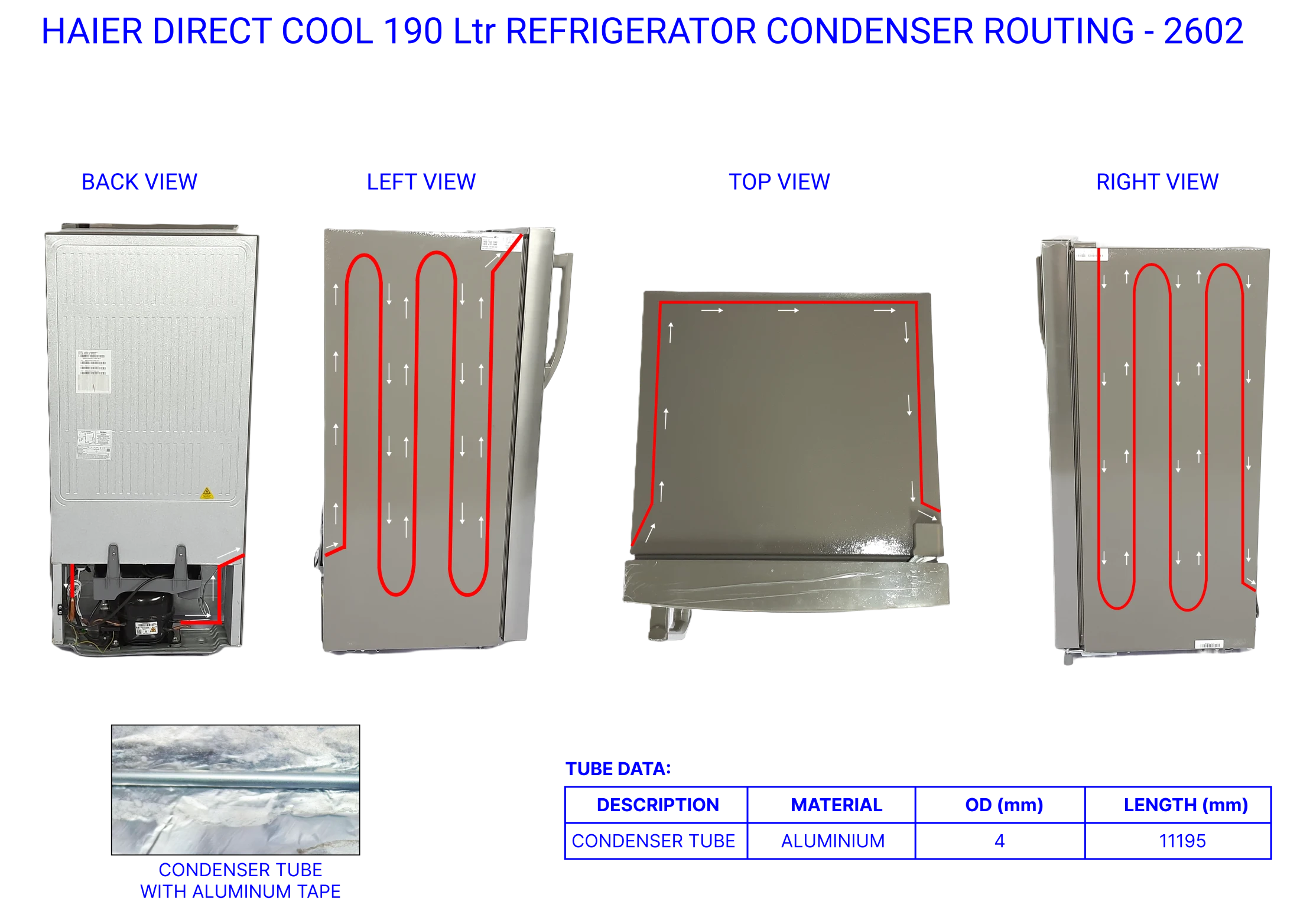

6. Condensation in Condenser Coils

This hot gas flows through the condenser coils on the outside back of the fridge, where it releases heat to the surrounding air and condenses into a liquid.

7. Pressure Drop via Capillary Tube

The liquid refrigerant passes through the capillary tube, where its pressure and temperature drop significantly.

8. Evaporation in Evaporator Coil

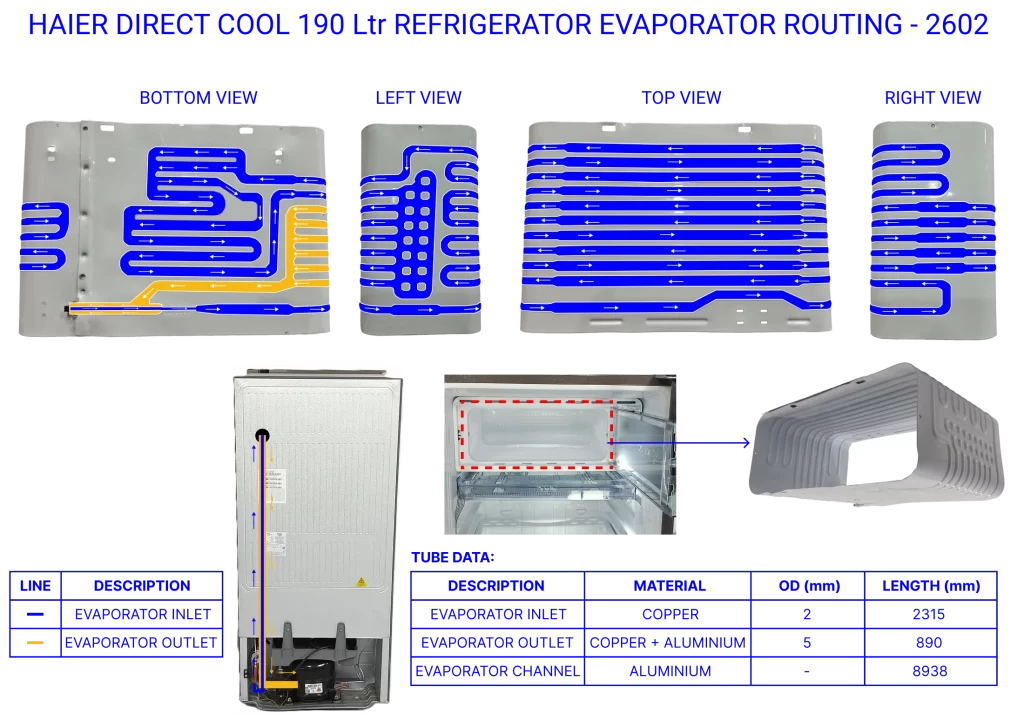

- The cold, low-pressure refrigerant enters the evaporator coil in the freezer compartment and evaporates by absorbing heat from the inside.

- This evaporation cools the freezer and refrigerator compartments and forms frost on the evaporator surface.

9. Refrigerant Returns to Compressor

The resulting low-pressure gas returns to the compressor to begin the cycle again.

10. Cooling Cycle Control

Once the desired temperature is reached, the thermostat opens, cutting power to the compressor and stopping the cooling.- This cooling cycle repeats automatically as the thermostat continuously monitors the internal temperature.

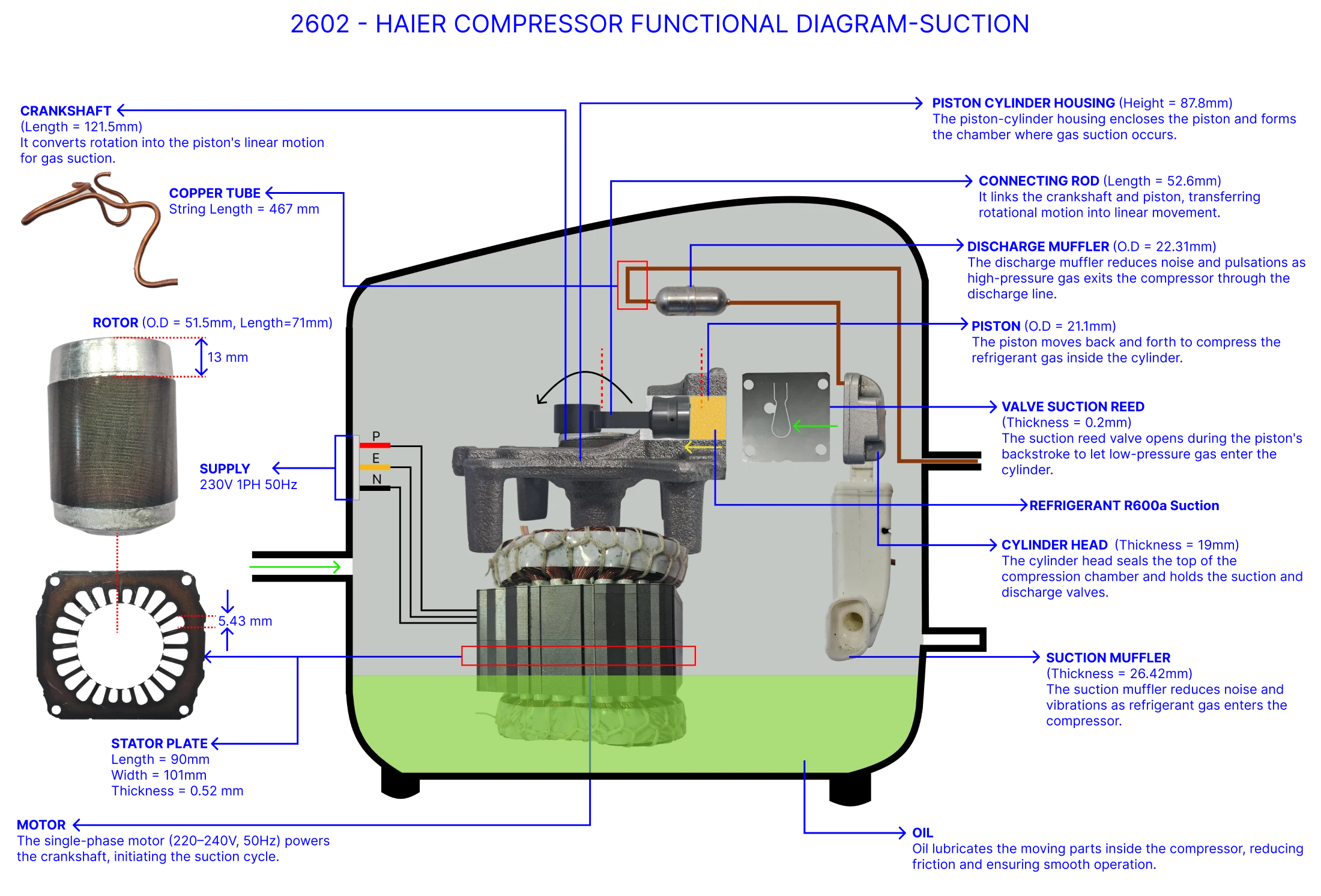

Refrigerator Compressor: Working Principle & Cycle

1. Power Supply Activated

When the fridge temperature rises above the set point, the thermostat closes, allowing 220–240V AC to power the single-phase motor inside the compressor.

2. Rotor Starts Rotating

The stator generates a rotating magnetic field that spins the rotor (Ø 51.5 mm), initiating the compressor cycle.

3. Crankshaft Driven by Rotor

The rotor motion drives the crankshaft (121.5 mm long), converting rotary motion into reciprocating motion through the connecting rod (52.6 mm).

Suction Stroke (Downstroke)

4. Piston Moves Downward

The crankshaft pulls the piston (Ø 21.1 mm) down inside the cylinder (87.8 mm height), increasing chamber volume and reducing internal pressure.

5. Suction Valve Opens

The pressure drop causes the suction reed valve (0.2 mm thick) to open, allowing low-pressure R600a refrigerant to enter the chamber.

6. Refrigerant Passes Through Suction Muffler

Refrigerant flows in through the suction muffler (26.42 mm thick), which dampens intake noise and vibrations.

7. Oil Splash Lubrication Begins

As the crankshaft rotates, it agitates the oil pool at the bottom. The motion splashes oil onto the piston skirt, cylinder walls, crankshaft, and connecting rod.

8. Oil Forms Protective Film

Oil forms a lubricating film between the piston and cylinder, reducing friction, sealing against leakage, and minimizing heat and wear.

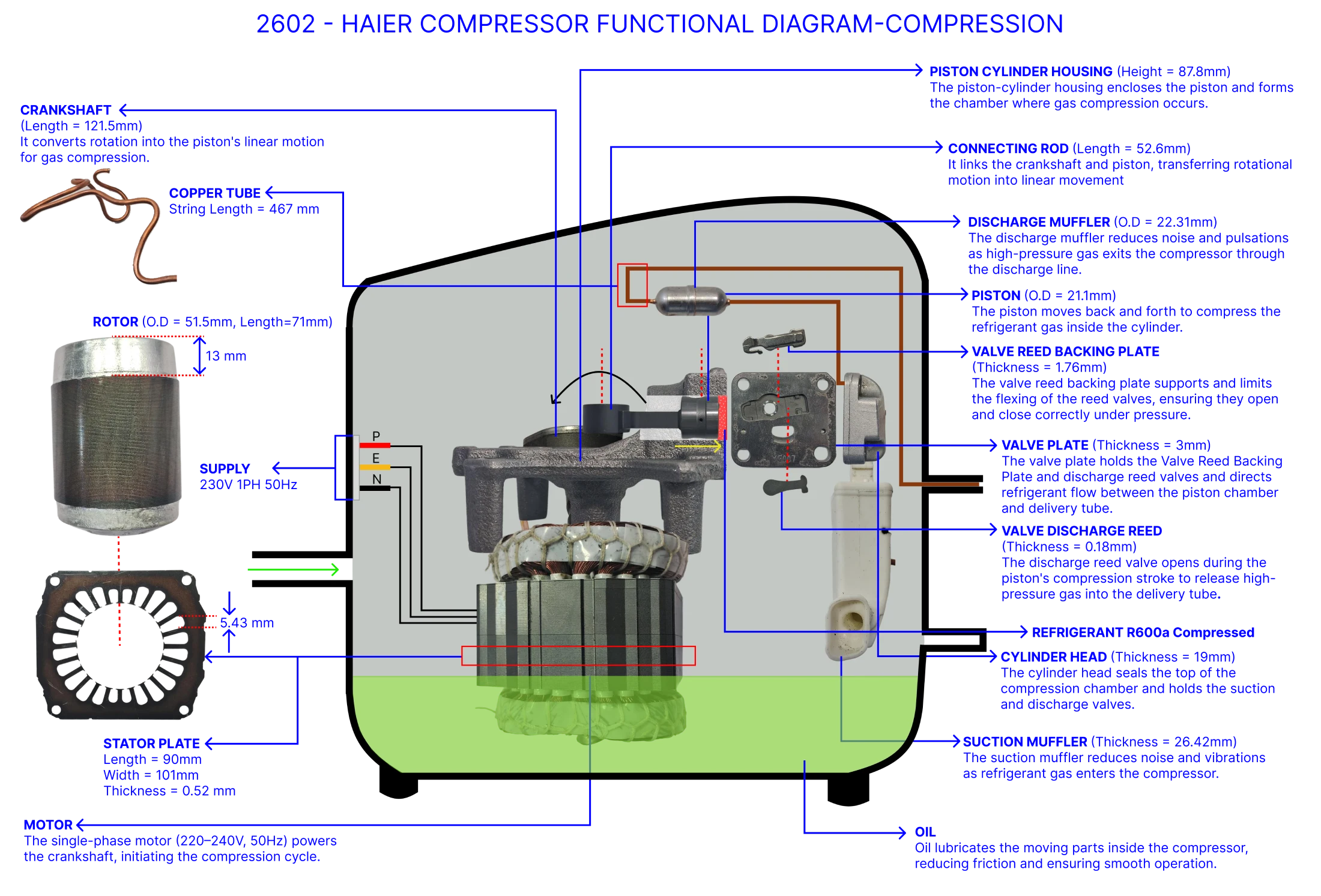

Compression Stroke (Upstroke)

9. Piston Moves Upward

The crankshaft pushes the piston upward, decreasing the chamber volume and increasing the pressure of the trapped refrigerant.

10. Suction Valve Closes

The rising pressure forces the suction valve to close, preventing backflow.

11. Refrigerant is Compressed

The refrigerant vapor is compressed into high-pressure, high-temperature gas suitable for heat rejection in the condenser.

12. Discharge Valve Opens

Once internal pressure exceeds that of the discharge line, the discharge reed valve (0.18 mm thick) opens.

13. Gas Exits Through Discharge Muffler

Compressed gas exits via the discharge muffler (Ø 22.31 mm), which smooths out pulsations and reduces discharge noise.

14. Valves Controlled by Valve Plate

A 3 mm valve plate and 1.76 mm backing plate guide and limit the motion of the reed valves, ensuring timely opening/closing based on pressure changes.

15. Continuous Lubrication and Cycling

With each rotation, oil continues circulating, maintaining lubrication. The cycle repeats until the thermostat cuts power when the target temperature is reached.

Bill of Materials (BOM)

The following table outlines key parts, their materials, approximate weights, and functions derived from teardown data:

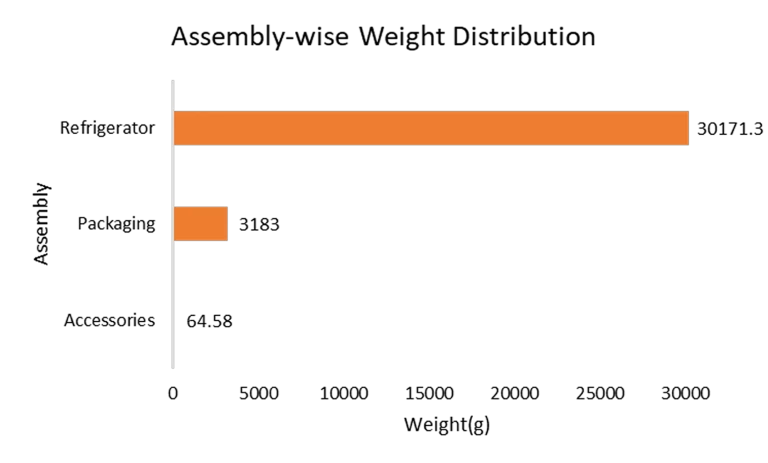

Assembly-wise Weight Distribution

- The refrigerator assembly contributes 90.3% of total weight, confirming that most material cost is concentrated in the core cabinet, liner, doors, and internal hardware.

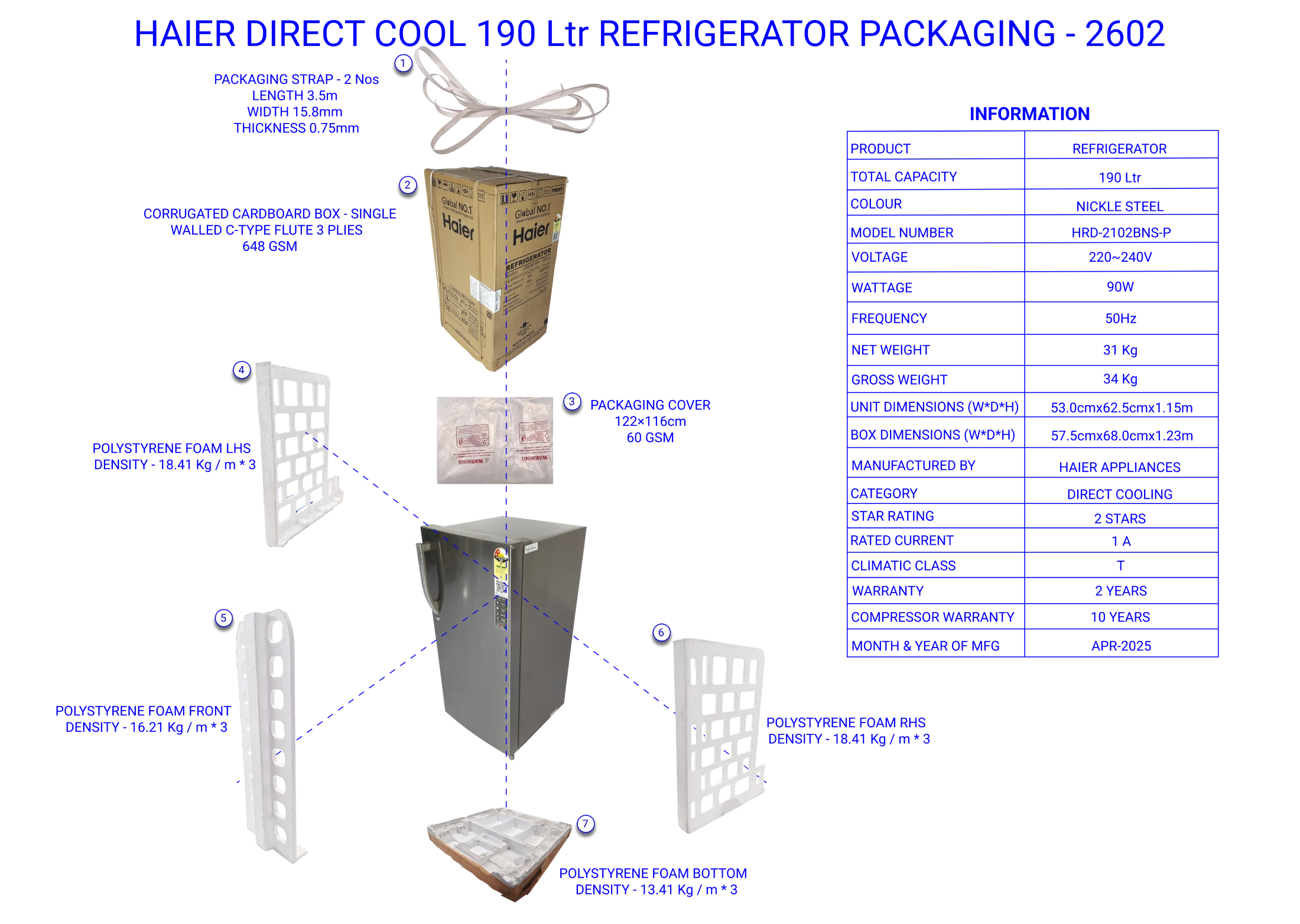

- Packaging alone accounts for 9.5% of the total weight (3.18 kg), Which is non-functional mass used purely for protection and logistics — highlighting a potential area for optimization.

- Accessories are negligible at 0.2%, indicating minimal impact on both cost and weight.

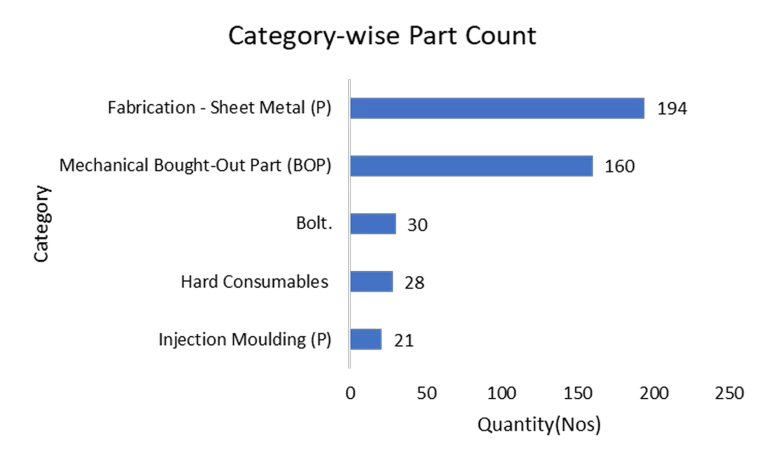

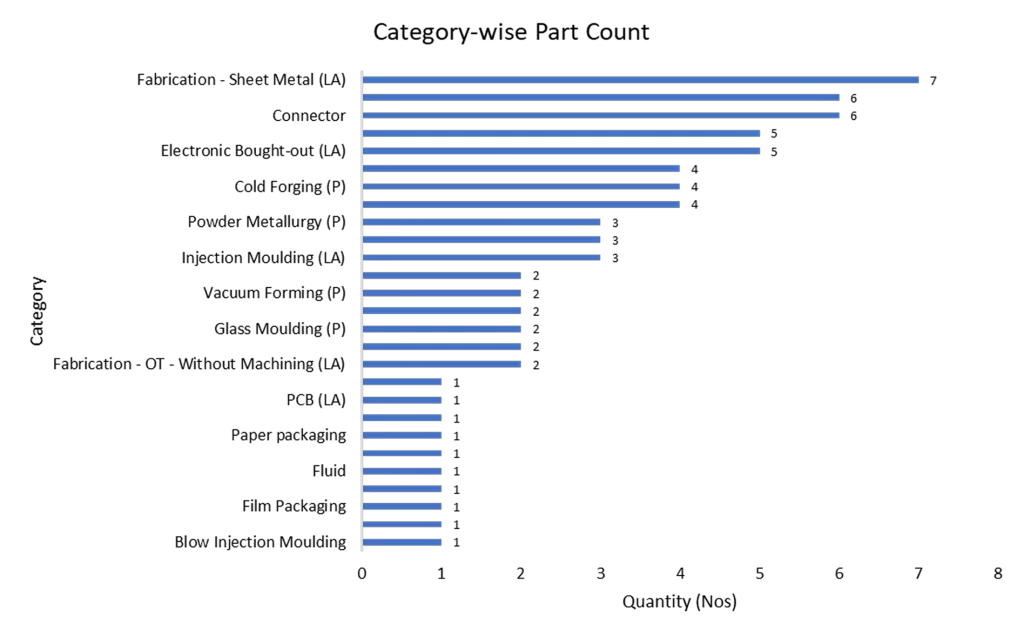

Part Count Distribution

- The BOM contains nearly 500 individual parts, showing high assembly complexity.

- Fabrication – Sheet Metal (P) and Mechanical BOPs dominate the part count with 193 and 160 parts respectively, forming the structural backbone and functional mechanisms of the refrigerator.

- All other categories like injection moulding, wiring harnesses, connectors, and packaging occur in small counts.

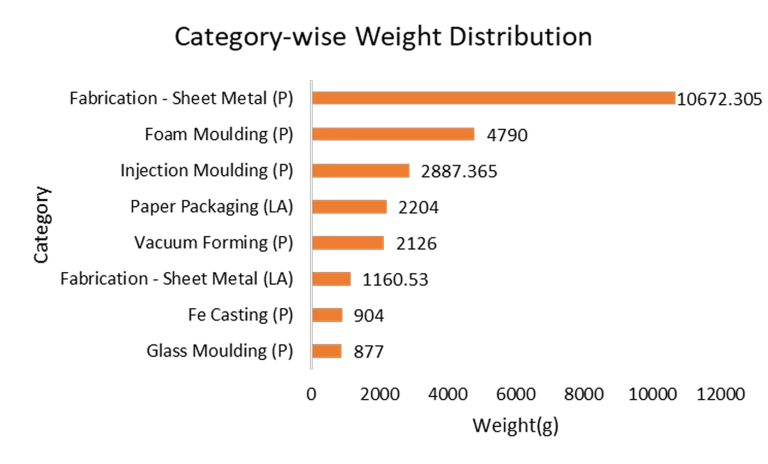

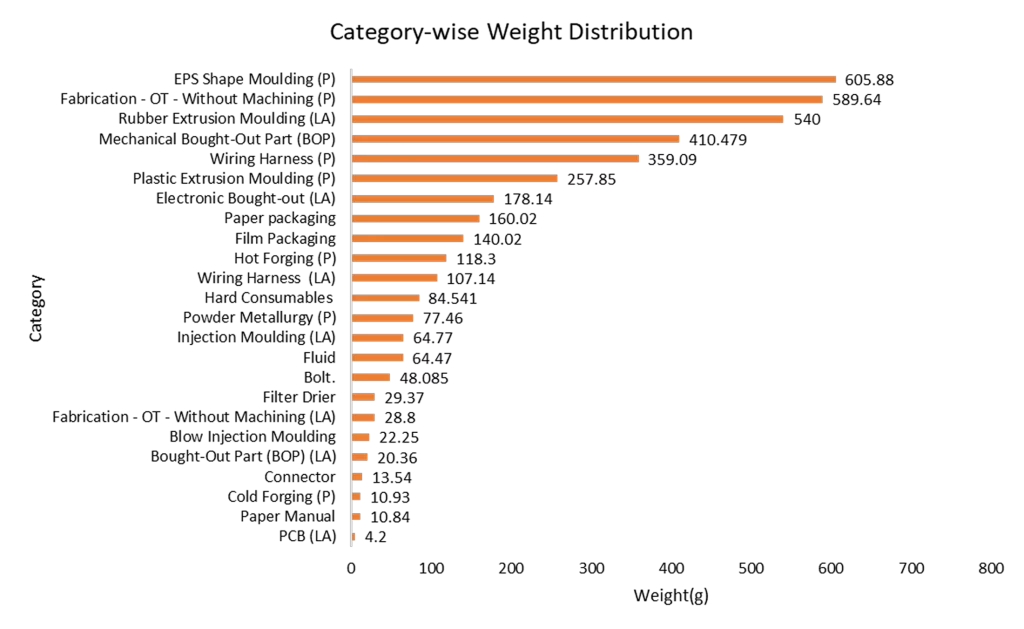

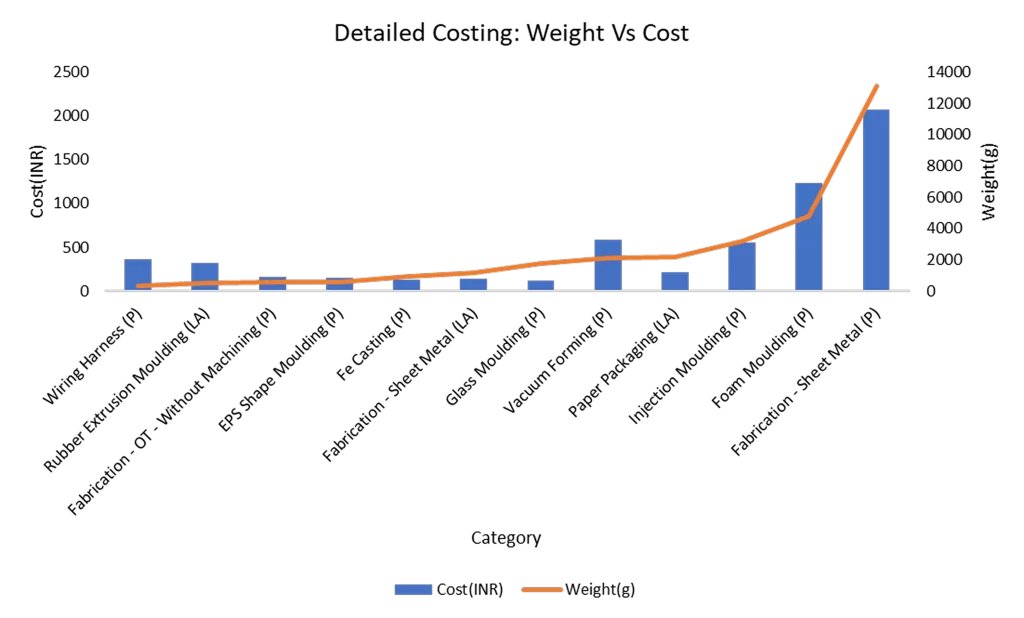

Weight Distribution by Manufacturing Category

- Fabrication – Sheet Metal (P) is the single largest contributor, weighing 10,672.31 g (47.4%) of total product weight.

- Foam Moulding (P) contributes 4,790 g (21.3%), showing the significant weight of insulation or foam parts.

- Injection Moulding (P) adds 2,887.37 g (12.8%), reflecting the plastic housing and structural parts.

- Paper Packaging (LA) and Vacuum Forming (P) together contribute 4,330 g (19.2%), highlighting that packaging adds substantial non-functional weight.

- Fabrication – Sheet Metal (LA) weighs 1,160.53 g (5.2%), Fe Casting (P) 904 g (4%), and Glass Moulding (P) 877 g (3.9%), representing other structural components.

- Other categories such as EPS Shape Moulding (P) (606 g), Rubber Extrusion Moulding (LA) (540 g), Wiring Harness (P & LA) (466 g), Plastic Extrusion Moulding (P)(258 g), Injection Moulding (LA) (65 g), Filter Drier (29 g), Blow Injection Moulding (22g), and lightweight parts like PCB (LA), Paper Manual, Cold Forging, Bolts, and Connectors each contribute less than 3% individually.

Detailed Refrigerator Should Cost Analysis

A detailed should-costing approach was used to estimate the manufacturing cost of the refrigerator.

The study considered material pricing, labor costs, production scale, and sourcing assumptions to establish a realistic benchmark.

Key assumptions applied in the analysis:

- The refrigerator is manufactured in India.

- An annual production volume of 40,000 units was considered for cost normalization.

- Material and labor cost benchmarks for Q1 FY25–26 were used as reference.

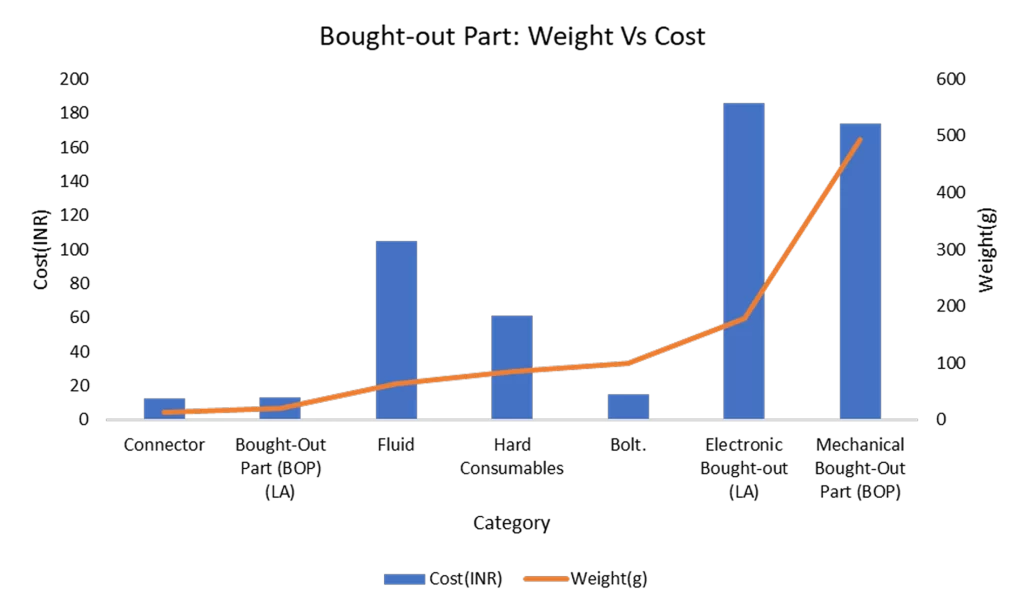

Bought-Out Parts – Analysis

Bought-out parts are light in weight but cost-sensitive.

- Electronics (PCB and controls), mechanical BOPs, and refrigerant fluid are the primary cost drivers.

- Smaller items like connectors, bolts, and consumables contribute negligible weight and cost.

- This mismatch between low mass and high cost underscores the need for careful sourcing and supplier management in bought-out categories.

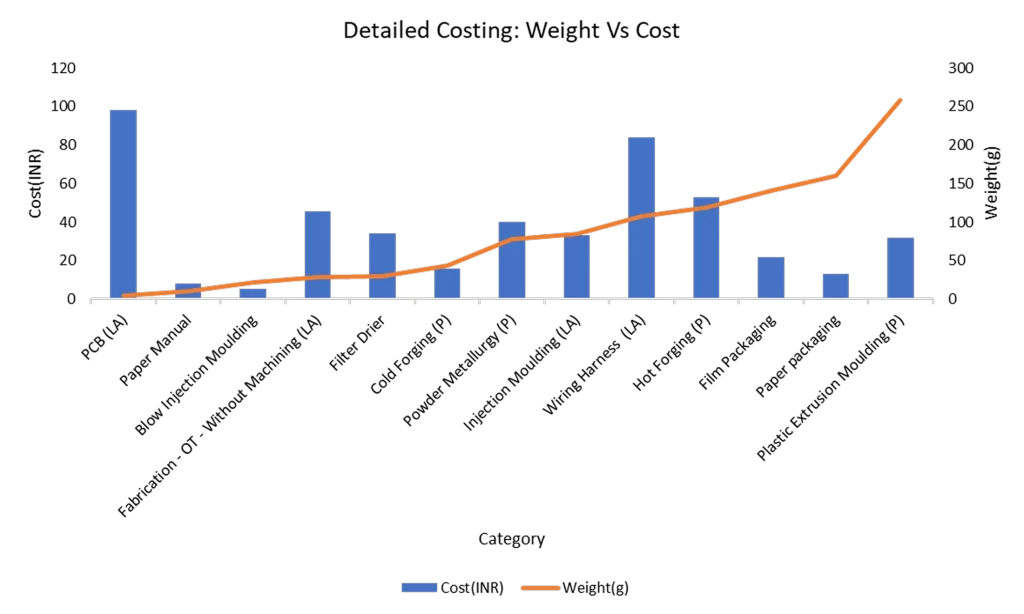

Detailed Refrigerator Should Costing – Analysis

Fabrication – sheet metal and foam moulding dominate both weight and cost. At the same time, wiring harnesses, rubber parts, and PCB show high cost despite low weight.

Should-Cost Analysis

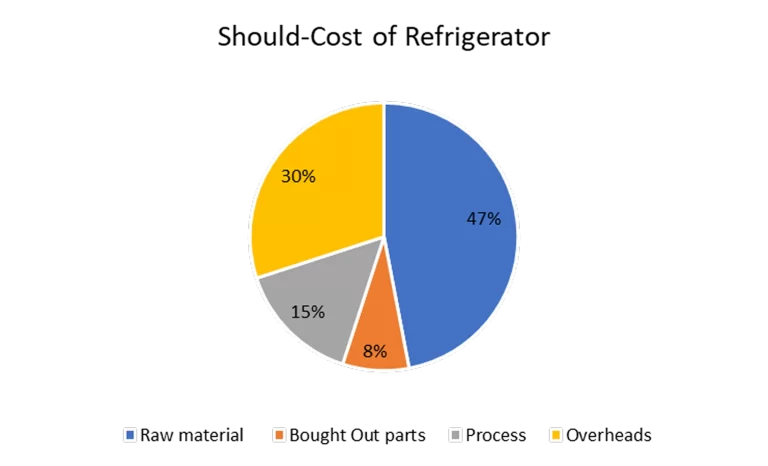

The should-costing study for the Refrigerator considers production scale, process requirements, and prevailing material and labor benchmarks. The cost structure is distributed as follows:

- Raw Materials – ₹4,760.20 (47%)

Primary contributor, driven by metals, plastics, and insulation foams. - Bought-Out Parts – ₹854.90 (8%)

Covers electronics, refrigerant fluid, and mechanical assemblies. - Processes – ₹1,505.00 (15%)

Includes fabrication-sheet metal, moulding, and assembly operations. - Overheads – ₹3,102.10 (30%)

Represents indirect manufacturing costs, logistics, and facility expenses.

Total Estimated Should-Cost: ₹10,222.20 per unit (India, 40k units/year).

This breakdown highlights a material-intensive cost structure, with raw materials and overheads together accounting for more than three-fourths of the total manufacturing

cost.

Insights Gained from the Teardown

- Fabrication – Sheet Metal (P) and Foam Moulding (P) together account for nearly 69% of the refrigerator’s total weight and a large share of cost, making them the most significant cost drivers.

- Rubber seals, wiring harnesses, and PCBs are lightweight yet carry disproportionately high costs, highlighting the importance of sourcing strategy.

- Packaging materials contribute nearly 9.5% of total weight but relatively little to cost, adding logistical bulk rather than functional value.

- Bought-out parts such as electronic controls and refrigerant fluid add critical functionality while accounting for a notable share of cost.

- High part count (~500) increases assembly complexity, driving handling, tooling, and process overheads.

Summary Table: BOM and Should-Cost Overview

- Production Volume Considered: 40,000 units/year (India)

- Total Assembly Weight: ~33.42 kilograms

- Estimated Should-Cost (India): ₹10,222.20 per unit

- Major Cost Drivers: Compressor, cabinet foam and door panel

- The compressor, costing ₹2077.15, is the most expensive component, making it the single largest cost driver in the product.

Conclusion: Refrigerator Cost Drivers & Sourcing Insights

This refrigerator teardown highlights the balance between heavy structural processes and lightweight but high-value components. Through BOM analysis and should-cost benchmarking, manufacturers can identify material-intensive categories, optimize sourcing of bought-out parts, and explore opportunities in packaging and assembly simplification.