Industrial Equipment Should Costing

Powered by xcPEP SaaS, Delivered by ASI Engineering

Should costing for industrial equipment and heavy machinery is the structured process of arriving at a true manufacturing cost - not by guesswork or supplier quotes, but by systematically mapping how the part or assembly is actually made.

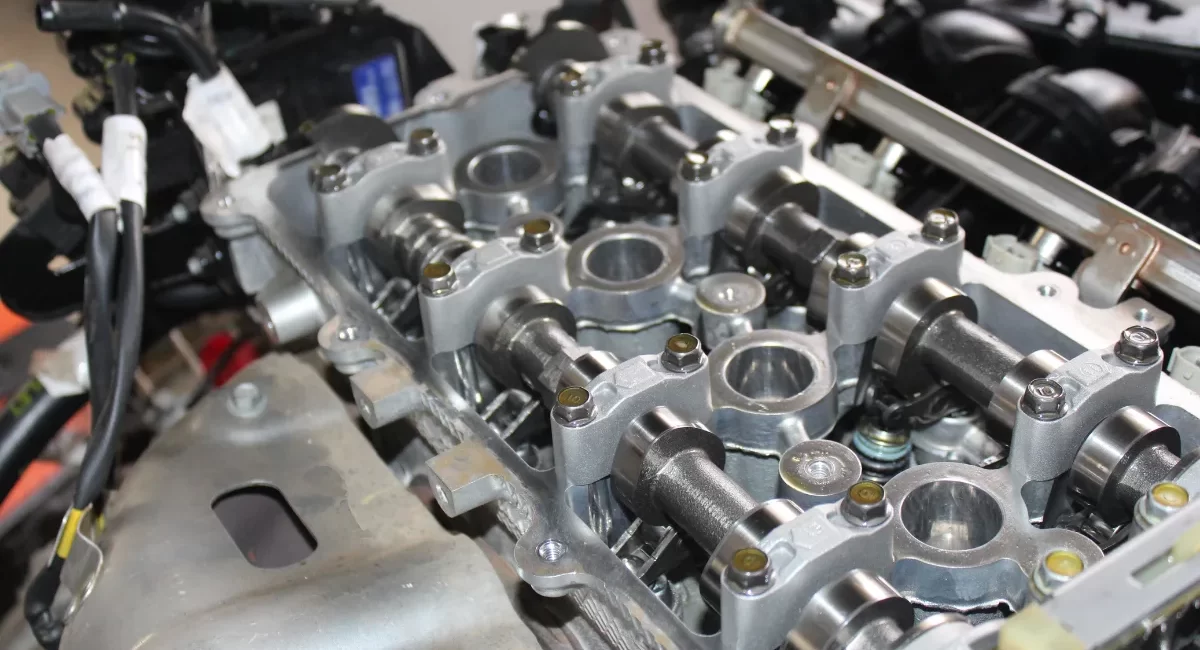

In this space, products are rarely straightforward. A single gearbox skid or pump assembly can involve welded frames, machined parts, bought-out drives, coating systems, hydraulic circuits, control panels, and test operations. Add to that low or medium volumes, engineered-to-order configurations, and region-dependent supplier bases - and traditional cost estimation methods simply fall short.

ASI Engineering executes a proven should costing methodology that begins with detailed teardown or drawing analysis, builds a process-realistic cost model, and then converts that model into a clear should cost value. This gives your team the data confidence needed for supplier negotiations, sourcing decisions, and cost reduction programs.

All of this is powered by xcPEP - the should-cost analysis software our engineers use to build and run these models. And for organizations that want to bring this capability in-house, xcPEP is also available as a SaaS platform, enabling your own teams to estimate and optimize costs with the same rigor.

Why traditional should costing tools fall short for

Industrial Equipment & Heavy Machinery

Should costing for industrial equipment and heavy machinery is fundamentally different from high-volume or standardized manufacturing. It’s not hard because the arithmetic is complicated - it’s hard because these products combine multiple technologies, diverse manufacturing steps, and region- and supplier-specific dependencies that most costing tools simply don’t capture.

Many of the so-called “should costing” solutions in the market are nothing more than BOM aggregators stacking line-item costs with generic multipliers, while others rely entirely on Excel spreadsheets filled with static rates and hidden assumptions. These methods may work for commodity parts but they collapse when applied to real industrial assemblies.

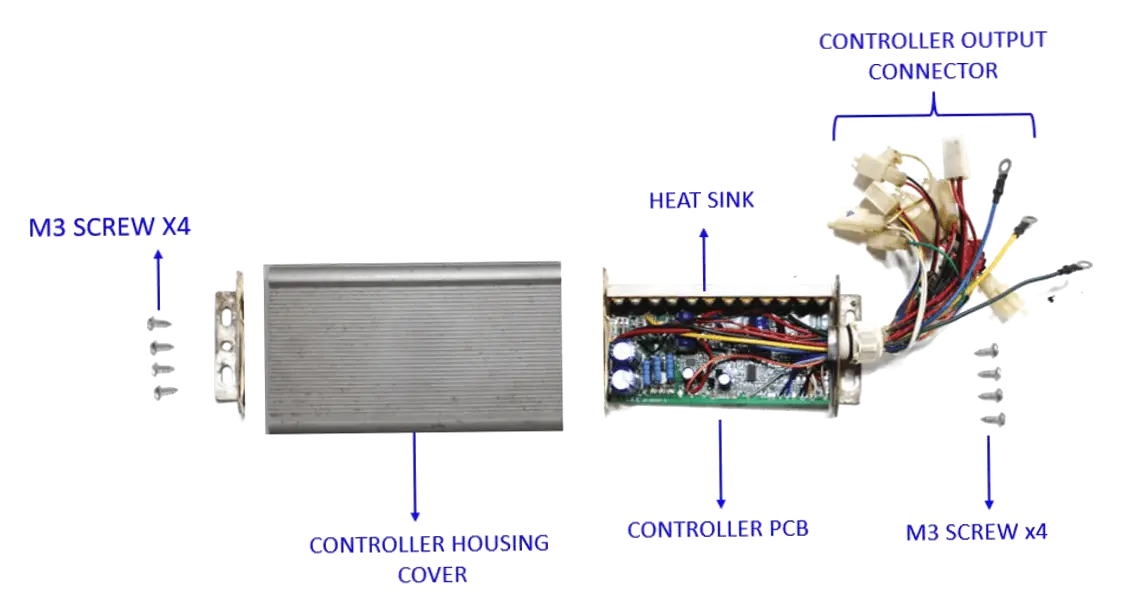

Consider something as common as a PLC control panel or a motor controller cabinet. This is not just a box with a few electronics - it’s a system built from sheet-metal enclosures, insulation and gasketing, electrical components like contactors, relays and PLCs, cable harnessing and routing, labeling, and rigorous testing. Every one of these elements involves different processes, materials, labour intensities, setup times, and sourcing dependencies. Flattening all of that into a handful of BOM line items may produce a clean number on paper, but that number rarely survives supplier negotiations, VA/VE reviews, or strategic sourcing discussions.

Traditional costing fails because it simplifies what is inherently complex - and that’s precisely where xcPEP provides a structured should costing framework, enabling ASI Engineering and our customers to model reality accurately.

Below are some of the key reasons why traditional costing approaches fall short in this space:

“What breaks the should cost of an industrial equipment isn’t one wrong number - it’s everything the spreadsheet never captures: real process steps, regional factors, volume effects and the people working in silos."

Multiple manufacturing technologies in a single assembly

Generic costing methods treat complex assemblies as if they were a single, flat line item. They ignore that cost is created through multiple overlapping manufacturing processes, each with its own setup time, tooling logic, and routing.

For example, a hydraulic powerpack involves fabricated tanks, welded frames, machined manifolds, pumps, valves, wiring, and coating. BOM rollups and simple multipliers can’t capture the layered process cost behind this kind of build.

Low to medium volumes with high variability

Many industrial equipment programs are built in small quantities or for specific customer requirements. In these cases, setup time, fixture changeovers, and the way operators work have a much bigger impact on cost than in mass production. But traditional costing methods are based on mass production assumptions - stable routing, low setup per part, and predictable cycles. That’s simply not the reality for this kind of equipment.

For example, when a CNC machine base frame is made in small batches, there are frequent setup changes, operator differences, and unpredictable cycle times. Generic costing ignores these variations and gives a number that looks smooth on paper but doesn’t reflect the actual cost.

Region and supplier dependency

A single “global” costing factor doesn’t work in real manufacturing. Costs change a lot depending on where the part is actually made. Things like machine-hour rates, labour costs, logistics, duties, and how the local supplier base works can completely change the final cost.

For example, if you cost the same industrial gearbox in India, Germany, and the U.S., the number will not be the same. Generic costing methods usually just apply a simple multiplier and ignore these differences - and the real gap shows up only during negotiations.

Welds, coatings, and testing are underestimated

Welding, coating, and testing are often treated as afterthoughts, even though they’re some of the most labour- and time-intensive steps in heavy equipment. Most costing methods reduce them to just another line item, which creates a big gap between the estimated cost and the real cost.

For example, a mining excavator bucket involves long weld lengths, surface prep, blasting, painting, and structural testing. Generic costing usually rolls all of this into a single “assembly” cost, which hides the actual effort and underestimates the total cost.

Integration between fabricated and bought-out parts

In most should costing exercises, fabricated and bought-out parts are treated separately, but the cost of putting them together is often ignored. Mounting, alignment, wiring, plumbing, and commissioning all add time and labour that generic costing methods don’t account for.

For example, a motorized conveyor system uses fabricated frames, rollers, gearboxes, motors, sensors, and controls. The cost of integrating these parts is real and significant, but most costing methods leave it out entirely.

Inconsistent input quality and fragmented data

Costing for industrial equipment often starts with incomplete or messy inputs. Teams may have old PDFs, partial drawings, rough BOMs, or teardown notes. Generic costing methods struggle with this kind of data and usually depend on assumptions and averages to fill the gaps.

For example, a heavy press retrofit project might begin with decades-old drawings and missing details. Without a structured way to handle these inputs, teams end up building costs on shaky ground.

Teams working in silos

In many companies, costing lives in separate spreadsheets: Design/Engineering builds one, Cost Engineering another, Procurement/Sourcing and Supplier Negotiation have their own, and so do VA/VE, Finance/Controlling, and sometimes Operations/Manufacturing Engineering. None of these files share the same assumptions on machine rates, scrap, duties, region, or even currency - so the numbers drift.

The result is predictable: everyone shows up to reviews with different versions of the truth, alignment takes weeks, and negotiations stall. There’s no shared platform, no audit trail, and no external validation of inputs. When decisions finally get made, they’re often based on whichever spreadsheet shouted loudest - not on a consistent, defensible should cost.

xcPEP Should Costing Software

The structured fix for complex industrial equipment should costing.

xcPEP is a should costing platform built to solve the real challenges of costing complex industrial equipment and heavy machinery. It’s designed for cost engineering, sourcing, design, and procurement teams that need speed, structure, and accuracy in their cost estimates.

With xcPEP, you can build cost models from scratch, use pre-built cost models from a large library, or customize them for your specific part or process. You can run scenario analysis to compare regions, suppliers, volumes, or manufacturing routes, and explore how cost changes with real inputs - not rough multipliers. It gives teams full transparency into every assumption, calculation, and parameter, so costing isn’t hidden behind spreadsheets or black boxes.

At the center of xcPEP is xcPROC, a cost data hub built and maintained by ASI’s data research team. It houses region-specific machine hour rates, raw material prices, operator wages, tooling costs, and logistics data - all updated continuously based on real manufacturing conditions. This ensures that every cost model is grounded in accurate and current data.

Together, xcPEP and xcPROC close the gap between BOM-based costing and real manufacturing cost logic. Whether you’re creating cost models for new designs, validating supplier quotes, or aligning cross-functional teams, xcPEP gives you a single, structured platform to do it confidently and fast.

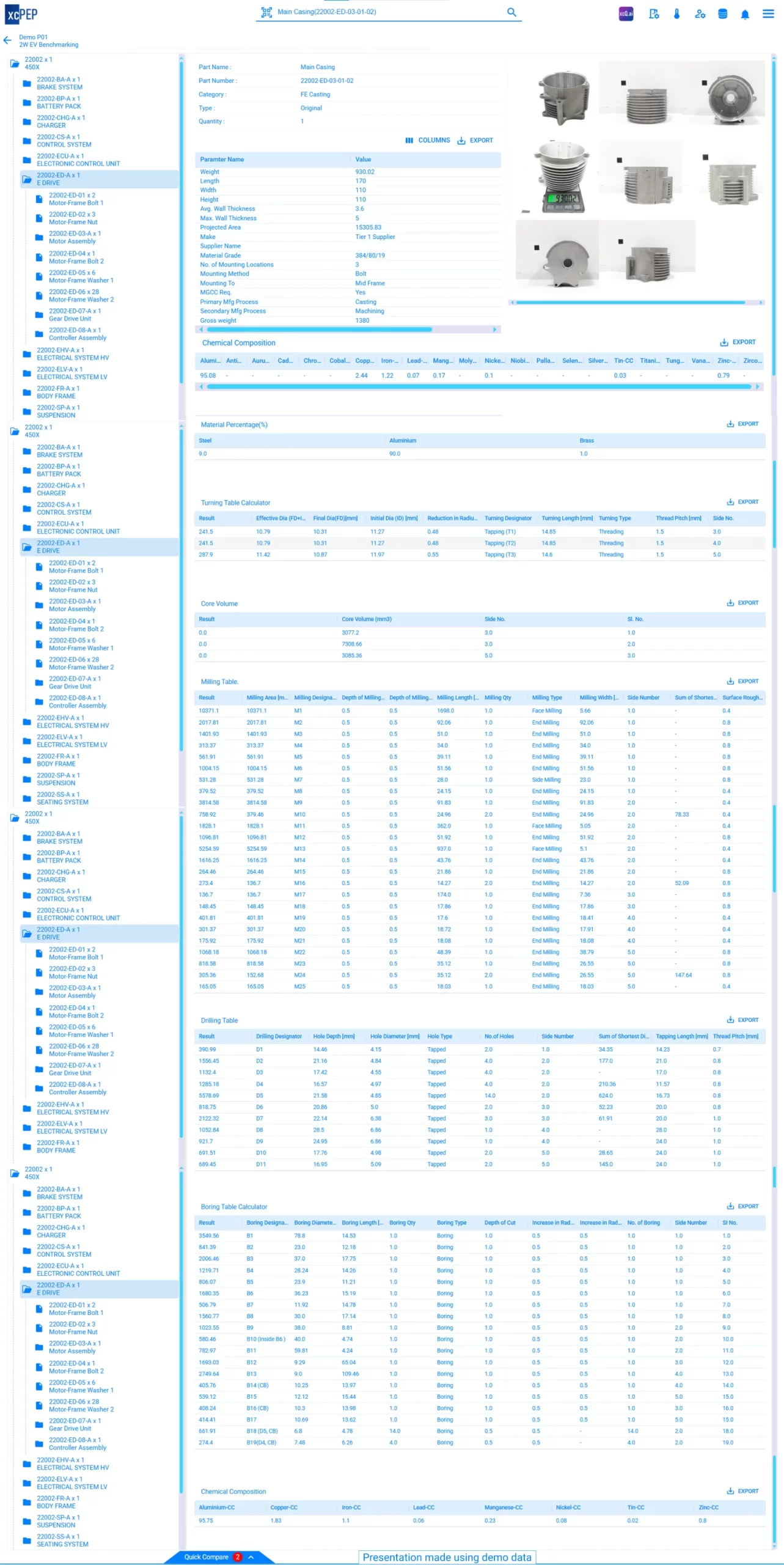

Detailed BOM and Part-Level Parameter Mapping

xcPEP enables detailed mapping of bill of materials (BOM) and part-level attributes using teardown studies & engineering drawings. For each part, more than 50 parameters are captured, including weight, geometry, box size, wall thickness, coating type, manufacturing category, material grade, surface area, and perimeter.

For mechanical components, data such as mounting methods, joining techniques, casting types, and machining details are also captured. For electrical components, the BOM includes semiconductor details, PCB attributes, number of layers, component placement, and manufacturer references. When drawings are available, parameters are extracted manually or via assisted parsing, enabling xcPEP to generate cost models directly from the data.

The BOM template is process-specific and fully editable. Users can modify it to add new parameters or build entirely new BOM templates as required. All mapped data is structured, traceable, and ready for use within the cost model engine.

Configurable Cost Models

xcPEP allows users to work with structured, editable cost models instead of static templates. Each cost model is built using equations and logic relevant to the specific manufacturing process being costed. Inputs such as material usage, cycle time, tool life, labour effort, and overhead allocation can be adjusted to match internal standards or supplier conditions.

Cost models in xcPEP are fully editable; users can modify them based on actual production flows. New Models can also be created from scratch for new processes, ensuring that cost logic remains relevant as products and technologies evolve. For specific requirements, additional parameters can be mapped into a model. For example, injection moulding models can be extended with user-defined fields beyond the defaults, allowing for deeper process-specific detail when needed.

Build-Your-Own Cost Models

For cases where standard cost models do not apply, xcPEP provides the ability to create fully custom models. Users can define process steps, assign formulas, and build part-specific costing structures from the ground up. Each model follows a consistent framework, allowing for integration with other platform modules. This flexibility ensures that niche processes, proprietary methods, or new product lines can be costed with the same level of control and consistency as standard components.

Input data required for these models, such as material prices, machine rates, or tooling norms, can be fetched from the xcPROC cost data service.

Built-in Cost Dashboards

xcPEP has in built dashboards that display cost breakdowns by part, process, material, supplier, and other filters. Users can view cost distribution as percentages or absolute values, enabling clear understanding of major cost drivers. No third-party BI tools are required; dashboards are built into the platform and update in real time as inputs or assumptions change. All data can be downloaded as Excel files for further analysis or sharing.

Scenario Simulation and Comparison

Users can create multiple scenarios for the same part or assembly by modifying key inputs such as production volume, material grade, process route, or supplier location. Each scenario is stored independently and can be compared using built-in tools. Graphical views allow users to see cost deltas and pinpoint which assumptions contributed to variation. This helps teams evaluate trade-offs before making sourcing or design decisions.

Cost Delta and Driver Analysis

When multiple scenarios or models are available, xcPEP highlights the changes in cost and identifies the key drivers. This helps teams understand how specific assumptions—like cycle time changes or material substitutions—impact final cost. The analysis is integrated into the comparison workflow, making it easy to trace outcomes back to decisions. It supports more informed discussions across engineering, sourcing, and finance.

xcPROC Cost Data Integration

xcPEP connects directly to xcPROC, ASI’s internal cost database. This allows users to access consistent values for raw material prices, machine-hour rates, labour costs, tooling norms, and more. All datasets are built and maintained by ASI and updated on a defined schedule. If a user needs data specific to a plant, region, or process, ASI can build and deliver that subset on request.

Users only subscribe to the datasets they need, and all data is formatted for direct use in xcPEP models. Since xcPROC is natively integrated with xcPEP, users do not need to depend on any third-party applications or external databases for costing inputs.

In Built Idea Tracker

xcPEP includes a dedicated module to capture cost-saving ideas generated during should-costing. Each entry records the proposal details, expected savings, source of the idea, and current status. Teams can use this feature to track progress, assign ownership, and quantify the impact of cost-reduction efforts. The module ensures that valuable insights from costing exercises are not lost and are tied to implementation.

Role-Based Access Control

xcPEP offers granular access control, allowing administrators to define who can view, create, or edit models and data. Permissions can be set at the module, part, or user level. This ensures that teams across engineering, sourcing, and finance have access only to the tools and data relevant to their work. The system supports parallel collaboration without compromising data integrity or control.

Multi-Team Collaboration

Multiple users from different functions can work on the same part or model simultaneously. Engineering teams can define the technical inputs, sourcing can simulate supply-side changes, and finance can view cost outputs—all within the same platform. Access is filtered by role, and activity is coordinated without overlap. This reduces delays and promotes transparency across functions.

Import Tools

xcPEP supports importing BOMs, technical specifications, and costing data from Excel, CSV, and XML formats. Part attributes and cost-related parameters can be bulk uploaded or mapped directly to model fields. This accelerates onboarding of new parts and supports integration with existing workflows. Import formats follow a consistent structure to maintain model integrity.

Custom Reporting and Downloadable Output

All outputs in xcPEP—including full cost breakdowns, comparison reports, and part summaries—can be downloaded in structured Excel formats. Reports are formatted for clarity and ready to be used in internal reviews, supplier discussions, or audits. This enables seamless communication between teams and across functions, while keeping a clear record of cost decisions.

API-Based Integration

The platform provides APIs for integration with external systems such as PLM, ERP, or reporting tools. Data can be exchanged bi-directionally, allowing updates to BOMs, supplier lists, or cost outputs to flow seamlessly between systems. Integration helps avoid duplication of effort and improves alignment with broader digital infrastructure.

xcPEP

xcPROC

Deploy xcPEP the Way That Works for You

Accelerate with ASI Engineering. Scale with xcPEP SaaS

Different organizations are at different stages in their should costing journey. That’s why xcPEP is designed to work in three flexible deployment models, so you can start fast, scale when you’re ready, or build a long-term capability inside your organization.

Execute Should Costing Projects with ASI Engineering

Delivered by ASI Engineering, Powered by xcPEP

Delivered by ASI EngineeringFor organizations that want to begin should costing quickly without setting up an internal team, ASI Engineering delivers turnkey should costing projects using xcPEP. Our team works directly with your physical parts or drawings to build process-realistic cost models that capture every step of manufacturing - machining, fabrication, coating, hydraulics, electrical systems, PCBs, sensors, actuators, and complete assemblies.

Using these cost models, we generate structured and defensible should cost values that are fully transparent. Every number can be traced back to its source - whether it’s process time, material utilization, or region-specific cost data. This gives your team complete visibility into how costs are built up, instead of relying on black-box estimates or generic multipliers.

This approach helps drive clarity in supplier negotiations, validate quotes with confidence, make informed make-vs-buy decisions, identify cost-down opportunities early in the product cycle, and plan sourcing strategies with real numbers rather than assumptions. The output is accurate, transparent, and actionable - enabling faster and more confident commercial and engineering decisions.

ASI Engineering also delivers dedicated cost reduction projects. By comparing your parts with competitor parts, identifying opportunities to optimize design, manufacturing routes, or sourcing strategies, and turning those findings into actionable recommendations, we help teams achieve measurable cost savings and improve sourcing leverage.

Because these projects are built entirely on xcPEP, the same cost models and data can be transitioned seamlessly to your internal team later if you choose to scale through the SaaS model.

Cost Reduction Studies for Industrial Equipment

xcPEP SaaS Model

Delivered by xcPEP, powered by your team

For organizations that want to own and scale their should costing capability in-house, xcPEP is available as a SaaS platform. We provide structured onboarding, training for your team, migration of legacy cost data, and ongoing support for new cost models, cost databases, and process updates.

Your engineers, sourcing, and procurement teams can work in one connected environment that brings process logic, cost data, and sourcing scenarios together. It eliminates scattered spreadsheets and conflicting numbers, so everyone works with the same transparent and defensible should cost value.

How xcPEP Can Be Deployed for Your Organization

Should Costing Lab - Build. Operate. Transfer

Your should costing center of excellence - built on xcPEP by ASI Engineering

For companies that don’t yet have an in-house should costing team and want to build long-term capability, we can set up a dedicated Should Costing Lab inside your organization.

Under the Build–Operate–Transfer model, ASI establishes the infrastructure, hires and trains the talent, deploys xcPEP, and sets up all required tools and processes to run a high-performing costing function. We jointly operate the lab with your team to stabilize workflows and then transfer full ownership to you once it’s ready to run independently.

This model is ideal for OEMs and Tier-1s looking to institutionalize should costing as a core capability, not just a project activity. It ensures speed at the start, control in the long run, and complete alignment with your organization’s sourcing and engineering strategies.

Build Your Own Should Costing Lab

Electro Mechanical Should Costing in xcPEP

Covers detailed should costing of every part's raw material, manufacturing process and overheads.

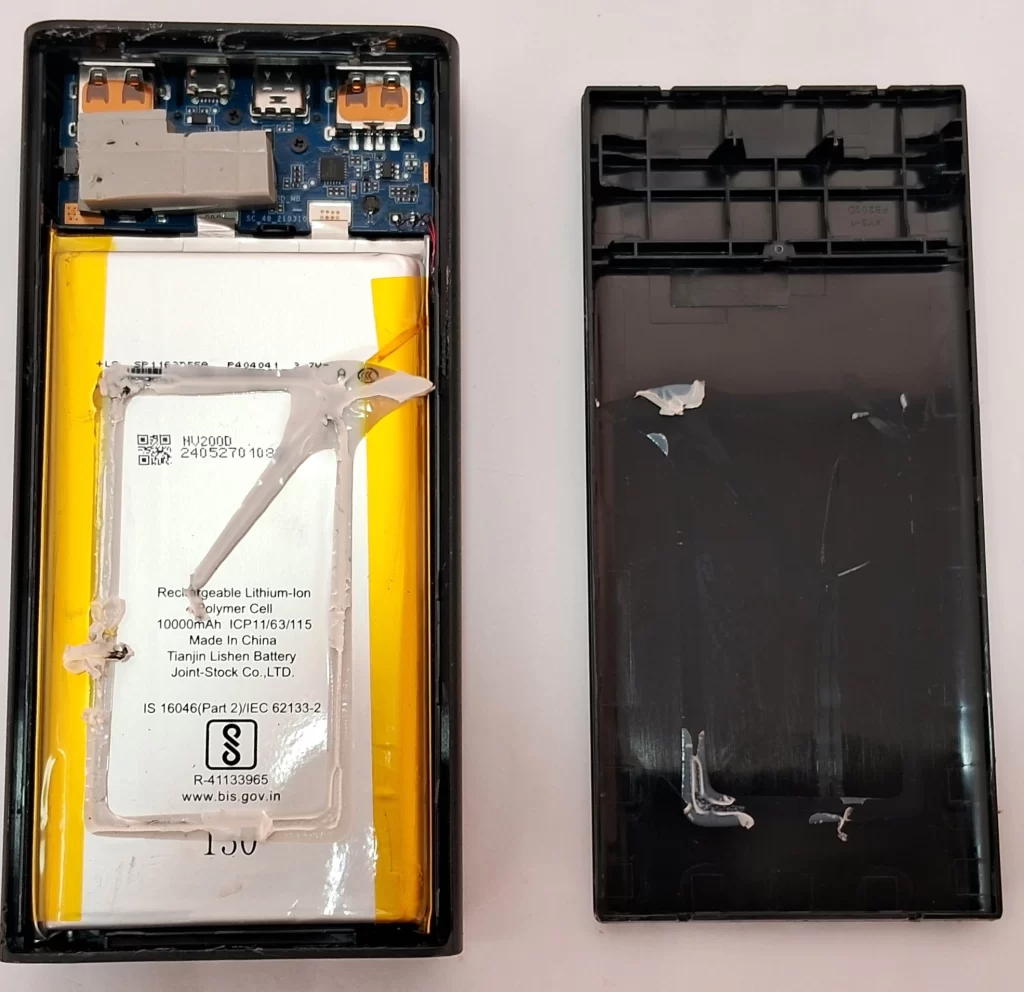

Industrial equipment is no longer purely mechanical. Most modern systems combine welded frames, machined parts, and hydraulic assemblies with electrical and electronic components such as PCBAs, control modules, sensors, switches, actuators, and wiring harnesses. A single product can include everything from pressure sensors and safety switches to process controllers, RTUs, and compressor housings - all integrated into one working system.

Costing these assemblies accurately requires a structured approach that covers both mechanical and electronic domains. This is where most costing tools fall short. Traditional methods and spreadsheets can handle fabrication and machining, but they fail to model electronics manufacturing, PCB assembly, control panel integration, harness routing, or embedded control modules with real production logic. As a result, the cost output is often incomplete, distorted, or unreliable.

xcPEP is purpose-built to solve this. Unlike BOM aggregators or Excel-based methods, xcPEP can cost mechanical, electrical, and electronic components in a single environment. Whether it’s pressure sensors, control switches, PCB assemblies, actuator modules, hydraulic manifolds, compressor units, or control cabinets, xcPEP applies real manufacturing logic, region-specific rates, and process parameters to deliver accurate, defensible should cost values across all domains - on one platform.

xcPEP's

Electronics Should Costing Module

Modern industrial systems go beyond welded frames and machined housings. They integrate electrical and electronic components such as PCB assemblies, control panels, sensors, actuators, switches, and wiring harnesses - all of which drive both cost and complexity. Most costing tools either ignore these components entirely or reduce them to line-item placeholders, leading to distorted cost estimates.

xcPEP is designed to solve this gap. It applies structured should costing methodology to model actual manufacturing logic for electronics: SMT placement, soldering, assembly routing, harness integration, panel utilization, machine selection, cycle times, and tooling logic. Each component - from high-density PCBAs to control modules and sensor-actuator systems - is costed using real process parameters and region-specific sourcing data from xcPROC.

This makes xcPEP ideal for industrial equipment like robotic control skids, PLC cabinets, actuator blocks, industrial sensors, and other electronic-heavy assemblies where traditional costing fails. The result is an accurate, defendable, and transparent should cost that includes the entire product, not just its mechanical shell.

Automation & Intelligence in xcPEP

For unprecedented speed scale & Precision

Accurate should costing starts with accurate data. xcPEP uses a suite of automated data capture tools to collect the physical and electronic information that drives cost models for industrial equipment. These tools allow teams to capture PCB component details, physical dimensions, and surface areas directly from the part - eliminating guesswork, drawings dependency, and manual entry.

The captured data flows seamlessly into xcPEP cost models, ensuring that every should cost value is based on real components and real geometry, not assumptions. Whether it’s identifying child parts on a control PCB, scanning the bounding box of a large welded frame, or calculating surface area for coating operations, these tools enable faster, more consistent, and more accurate cost modeling for complex industrial assemblies.

AI-Based PCB Component Identification

ASI Engineering uses AI-driven imaging to automatically detect and classify child components on PCBs such as ICs, resistors, capacitors, connectors, and other discrete parts commonly found in PLCs, sensor modules, and actuator controllers. This data is mapped to xcPROC and automatically populates the electronic BOM inside xcPEP, reducing manual work and improving costing accuracy for control electronics.

Bounding Box Dimension Capture System

For mechanical and structural parts like welded frames, castings, hydraulic manifolds, or panel enclosures, laser scanning is used to capture accurate length, width, and height in seconds. This geometric data is directly pushed into xcPEP to calculate blank size, material volume, packaging density, and logistics parameters, grounding cost models in real dimensions.

Automated Projected Area Capture System

For stamped, fabricated, or coated parts such as covers, housings, or mounting plates, xcPEP’s imaging system extracts the true projected surface area. This data is used to calculate finishing, painting, plating, or treatment costs, eliminating dependency on manual drawings and improving BOM consistency.

Use Cases

Internal Cost Lab Setup

xcPEP was deployed to set up an internal cost lab for a global industrial equipment manufacturer with product lines spanning pumps, compressor systems, automation modules, and control cabinets.

The ASI Engineering team managed the entire setup - migrating legacy costing data, configuring part templates, and integrating region-specific input rates using the xcPROC database. This included process routing logic for welded frames, machined housings, hydraulic manifolds, PCB assemblies, and sensor-actuator modules.

ASI worked alongside the client’s engineering and sourcing teams during the initial phase to execute the first few costing projects, demonstrating how to structure process-realistic cost models and simulate sourcing alternatives. The engagement followed a Build–Operate–Transfer (BOT) model. Once the lab was stabilized, full control was handed over to the client. Today, their team runs the lab independently, with ASI providing regular data updates and technical support as needed.

Should-Costing for New Part Development

A leading automation solutions company engaged ASI Engineering to define cost targets for a new robotic control skid during its early concept phase.

The ASI Engineering team built structured cost models directly from CAD and preliminary BOMs - well before supplier sourcing had begun. The models covered key subassemblies, including the welded base frame, machined housing for the hydraulic unit, PCB control module, sensor-actuator blocks, and electrical panels.

Using xcPEP, inputs were configured with validated data from xcPROC - including material grades, machine-hour rates, welding and machining logic, SMT process assumptions, and logistics factors across sourcing regions. As the design evolved, the models were continuously updated to reflect geometry and process changes.

This approach enabled the client’s engineering and procurement teams to align early on realistic cost targets, make design trade-offs based on cost impact, and enter sourcing discussions with a clear internal reference — avoiding late-stage surprises.

Fact Packs for Supplier Negotiations

A manufacturer of industrial process equipment engaged ASI Engineering to support negotiations for a new line of actuator assemblies and control cabinets.

ASI built detailed part-level cost models covering welded structures, machined components, PCB control boards, harness assemblies, and power supply units. Each model reflected actual manufacturing steps such as weld sequencing, machining setup, surface treatment, coating, SMT placement, and final testing - all configured with real-world input rates from xcPROC.

The outputs were compiled into fact packs showing expected cost breakdowns, key assumptions, and cost drivers. These structured packs gave the sourcing team a clear baseline to challenge inflated conversion costs, negotiate confidently, and drive targeted cost reduction actions.

How are we different?

We build cost engineering technology. Our core products, xcPEP for should cost modelling and xcPROC for cost data, form a powerful ecosystem supported by engineering services that speed customer adoption. While we may resemble consulting or benchmarking firms, the similarity is only superficial; our strength lies in the technology we create.

|

ASI vs. Management Consultants vs. Benchmarking Companies

Approaches to Cost Optimization for Consumer Electronics Manufacturers

|

||

| ASI – Engineering-Led Cost Transformation | Management Consultants | Benchmarking Companies |

|---|---|---|

| Engineering-led cost transformation using xcPEP & xcPROC, tailored for Consumer Electronics makers. Focus on sustainable, structural cost reduction across full product lifecycles. | Strategy-focused consulting aimed at solving isolated problems. Engagements are billable-hour driven and often lead to recurring cost challenges. | No pre-existing Consumer Electronics database. Deliverables based on expensive, one-off teardown or reverse-engineering projects. |

| Transparent Should Costing for every part, adapted to each manufacturer’s supply base and production process. Highly detailed, data-driven simulations enabling targeted cost-reduction initiatives. | Relies on SME expertise and generic industry data. Often produces incremental changes without addressing systemic cost drivers. | Costing often based on simplistic formulae from limited teardown samples. Insights rarely capture the complexity of electronics manufacturing and electronics child part sourcing. |

Proprietary platforms:

| General financial models and operational frameworks. Lacks manufacturing-specific cost simulation capabilities. | Uses ad-hoc analysis tools for each engagement. No scalable platform for repeatable, accurate cost estimation. |

| Measurable, sustainable cost reductions with direct impact on margin and competitiveness. | Recommendations improve current state but may not deliver optimal or lasting results. | Outcomes are slow, costly, and often fail to justify the investment. |

| Rapid portfolio-wide analysis with live costing tools – weeks, not months. | Multi-month projects from start to final report. | Slow, custom project timelines with long lead times for any usable insights. |

Our Core Objective

|

Engineering Led Cost Transformation

Of Consumer Electronics Manufacturers

|

||

| Challenge | ASI Solution | Value |

|---|---|---|

Key Challenges

|

Our Framework

|

Business Impact

|

| Core Technology Platforms | ||

|

xcPROC Procurement Intelligence

|

xcPEP Costing Engine Precise Should Costing

|

xcPEP Idea Module Automated Design & Commercial Idea Generation

|

| Build - Operate - Transfer Engagement Model | ||

|

Phase 1: Build Detailed Should-Costing Foundation

|

Phase 2: Operate Idea Generation & Implementation

|

Phase 3: Transfer Cost Engineering Function Handover

|

|

|

|

| Deliverables & Outcomes | ||

Immediate

|

Medium-Term

|

Long-Term

|

Product Studies

Cost engineering studies executed by ASI Engineering Team .

This section features teardown-based costing projects conducted by ASI Engineering team across a range of complex industrial assemblies - including hydraulic motors, actuators, pumps, control cabinets, compressor systems, BLDC motors, and PCB control boards.

Every image, model, and cost breakdown shown here is based on ASI’s own internal work. These studies demonstrate how structured should costing can be applied to real-world parts and assemblies, using manufacturing logic, accurate process routing, and validated regional cost inputs.

From welded frames and cast housings to PCBA control modules and actuator assemblies, each study shows how detailed part-level costing helps trace true cost drivers, explain product complexity, and benchmark sourcing alternatives. All cost models are created in xcPEP, with rate data and routing configurations pulled from xcPROC, ensuring traceable and defensible cost outputs.