Automotive

ASI Engineering is the in-house services team at Advanced Structures India, dedicated to supporting users of our SaaS platforms : xcPEP, our should cost analysis software used extensively for automotive should costing and xcPROC, Should Cost Data Hub.

We facilitate smooth onboarding to xcPEP and, when needed, support the setup of in-house cost labs at customer locations. We also undertake custom projects in target costing, cost benchmarking, and cost reduction idea generation.

Years of working with Automakers

And more vehicles torn down and costed

Automotive OEM Customers

The following are project-based services we offer to customers, built on and delivered through our xcPEP and xcPROC platforms.

Should Costing

We conduct should costing on your or competitor vehicles, using drawings or teardowns of physical parts for analysis.

Cost Reduction Studies

We compare your and competitors' vehicles part by part, across cost drivers, to generate impactful cost reduction ideas.

Onboarding

We tailor xcPEP to your products, suppliers, and locations, and build customer raw material, MHR, and LHR datasets.

Cost Lab B-O-T

We set up a cost lab in your organization, develops SOPs, train your team through live projects and deliver a functional cost lab.

Deployment and Cost Lab Build-Operate-Transfer are services through which the ASI Engineering team ensures xcPEP, our automotive should costing software is properly configured and effectively utilized for automotive should costing and related applications.

How are we different?

We build cost engineering technology. Our core products, xcPEP for should cost modelling and xcPROC for cost data, form a powerful ecosystem supported by engineering services that speed customer adoption. While we may resemble consulting or benchmarking firms, the similarity is only superficial; our strength lies in the technology we create.

|

ASI vs. Management Consultants vs. Benchmarking Companies

Approaches to Automotive Cost Engineering & Value Optimization

|

||

| ASI – Engineering-Led Cost Transformation | Management Consultants | Benchmarking Companies |

|---|---|---|

| End-to-end engineering-led cost transformation using xcPEP & xcPROC. Focus on sustainable, structural cost reduction across the entire product portfolio. | Strategy-driven consulting projects aimed at solving one-time problems. Engagements are billable-hour focused and often lead to recurring issues over the years. | Vehicle and component benchmarking using existing databases of 3D scans and past teardowns. Limited focus on the latest market-relevant technologies. |

| Transparent Should Costing for every part, with assumptions adapted to each company's products, supply chain, and manufacturing reality. Highly detailed, data-driven simulations for accurate cost estimation and reduction planning. | Relies heavily on subject matter experts and experience-based insights. Produces directional improvements but often lacks full product portfolio coverage. | Uses thumb-rule or formula-based costing, often less accurate than internal OEM/Tier-1 methods. Delta analysis from old models offers limited actionable insights. |

Proprietary platforms:

|

General consulting toolkits, templates, and financial models. No proprietary engineering cost simulation platforms. | In-house teardown archives and CAD scans. Data mostly from outdated or obsolete vehicle models. |

| Measurable, sustainable cost reductions. Direct impact on EBITDA, sourcing efficiency, and competitiveness. | Recommendations that improve status quo but may not represent optimal or lasting solutions. | Occasional cost ideas, but low hit-rate and limited relevance to current regulatory and market demands. |

| Rapid analysis with live costing tools – weeks for entire portfolio costing. | Project timelines often span months from kickoff to final report. | Data compilation and reporting from archives – timelines vary, but insights often outdated by delivery. |

Our Core Objective

|

Engineering Led Cost Transformation

Of Automotive OEMs and Tier 1 Suppliers

|

||

| Challenge | ASI Solution | Value |

|---|---|---|

Key Challenges

|

Our Framework

|

Business Impact

|

| Core Technology Platforms | ||

|

xcPROC Procurement Intelligence

|

xcPEP Costing Engine Precise Should Costing

|

xcPEP Idea Module Automated Design & Commercial Idea Generation

|

| Build - Operate - Transfer Engagement Model | ||

|

Phase 1: Build Detailed Should-Costing Foundation

|

Phase 2: Operate Idea Generation & Implementation

|

Phase 3: Transfer Cost Engineering Function Handover

|

|

|

|

| Deliverables & Outcomes | ||

Immediate

|

Medium-Term

|

Long-Term

|

Product Studies

Our engineers regularly undertake internal projects on products of interest. These initiatives help enhance our solutions for specific product categories and also generate demo data for customers to evaluate. Below are blogs showcasing the outcomes of these studies.

Should Cost Models for Automotive Should Costing

Comprehensive, process-wise costing built inside xcPEP by ASI Engineering.

Automotive should costing begins with clean, process-wise cost models. At ASI Engineering, we build part-level models using actual manufacturing logic, routing, machine time, tool wear, and regional cost inputs. All models are created inside xcPEP, our structured should cost analysis software, and are used by OEMs and Tier-1s for design validation, supplier benchmarking, and cost reduction. xcPEP is a cloud-native platform, enabling secure, real-time collaboration across teams and locations.

From injection moulding and stamping to machining, testing, and packaging, each process is modelled using our proven should costing methodology. This ensures consistency, traceability, and speed in every automotive should costing engagement.

Should Cost Models for Plastic Moulded Automotive Parts in xcPEP – Should Cost Modelling Software

- Film Packaging

- Polyethylene (PE) Films

- Polypropylene (PP) Films

- Polyethylene Terephthalate (PET) Films

- Biaxially Oriented Polypropylene (BOPP)

- Cast Polypropylene (CPP)

- Biaxially Oriented Polyester (BOPET)

- Amorphous Polyester (APET)

Thermoforming

- Vacuum Forming

- Pressure Forming

- Drape Forming

- Twin-Sheet Forming

- Foam Moulding

- Structural Foam Moulding

- Architectural Foam Moulding

- Foam Crown Moulding

- Stucco Foam Trim

- EPS Shape Moulding

Extrusion Moulding – Plastic & Ceramic

- Direct (Forward) Extrusion

- Indirect (Reverse) Extrusion

- Hydrostatic Extrusion

- Blown Film Extrusion

- Sheet/Film Extrusion

- Tubing Extrusion

- Coextrusion

- Extrusion Coating

Plastic Rota Moulding

- Clamshell Machine

- Shuttle Machine

- Carousel Machine

Injection Moulding – Thermoplastic

- High-Pressure Injection

- Micro Injection Moulding

- Gas-Assisted Injection

- Thin-Wall Packaging Moulding

Injection Moulding – Thermoset

- Transfer Moulding

- Compression Moulding

- Reaction Injection Moulding (RIM)

- Blow Moulding

- Extrusion Blow Moulding

- Injection Stretch Blow Moulding

- Accumulator Head Blow Moulding

Should Cost Models for Rubber Moulded Parts

- Compression Moulding – Rubber

- Hydraulic Compression Moulding

- Transfer Compression Moulding

- Preformed Rubber Blank Moulding

- Closed Mold Curing

- Rubber Sheet Moulding

- Extrusion Moulding – Rubber

- Hot Feed Extrusion

- Cold Feed Extrusion

- Microwave Curing Extrusion

- Steam Vulcanization Extrusion

- Salt Bath Curing

- Autoclave Curing

- Injection Moulding – Rubber

- Liquid Injection Moulding (LIM)

- Vacuum Injection Moulding

- Rubber Transfer Injection

- Cold Runner Injection Moulding

- Injection Moulded Seals & Gaskets

- Extrusion Moulding – Rubber & Plastic

- Dual Extrusion (Hard-Soft Combinations)

- Co-extruded Weather Seals

- TPV and EPDM Hybrid Extrusion

- Rubber-Plastic Strip Profiles

- Edge Trim Extrusion

Should Cost Models for Metal Formed Parts

- Cold Forging

- Cold Heading

- Cold Extrusion

- Cold Impact Extrusion

- Coining

- Cold Roll Forging

Ferrous Casting – Sand Casting

- Green Sand Casting

- Resin-Bonded Sand Casting

- No-Bake Sand Casting

- Shell Moulding

- Lost-Foam Casting (Ferrous)

Hot Forging – Gear

- Upset Forging of Gear Blanks

- Cogging

- Skiving & Burnishing

- Finish Forging

Hot Forging – Crankshaft

- Preform Forging

- Rotary Forging

- Impression-Die Forging

- Finish Forging & Trimming

- Powder Metallurgy

- Cold Press & Sinter

- Hot Isostatic Pressing (HIP)

- Metal Injection Molding (MIM)

- Powder Forging

Spring – Cold Wound

- Compression Spring Coiling

- Extension Spring Coiling

- Torsion Spring Coiling

- Wire Straightening & Stress Relieving

Spring – Hot Wound

- Hot Coil Winding

- Ring Spring Forming

- Shot Peening

- Annealing

Substrate – Metallic

- Aluminum Substrate Bonding

- Copper Core Substrates

- Metal-Insulated Substrates (IMS)

- Heat-Sink Metal Cores

- Zinc Casting – HPDC

- Hot-Chamber Die Casting

- Cold-Chamber Die Casting

- Vacuum Die Casting (Zinc)

- Squeeze Casting

Zinc Casting – GDC

- Tilt-Pour Gravity Casting

- Low-Pressure GDC

- Slush Casting

- Permanent-Mould Casting

Aluminium Casting – HPDC

- Cold-Chamber HPDC

- Hot-Chamber HPDC

- Vacuum HPDC

- High-Pressure Die Casting (Al Alloys)

Aluminium Casting – GDC

- Tilt-Pour Permanent-Mould Casting

- Slush Casting

- Low-Pressure Permanent-Mould

- Semi-Solid Rheo Casting

- Brass Casting – LPDC

- Bottom-Fill LPDC

- Counter-Gravity LPDC

- Semi-Solid LPDC

- Hot-Chamber LPDC

Brass Casting – GDC

- Tilt-Pour Gravity Casting

- Permanent-Mould GDC

- Centrifugal Casting (Brass)

- Sand-Mould Gravity Casting

Hot Forging – Roll

- Cogging-Mill Roll Forging

- Controlled Rolling

- Ring Rolling

- Scale-Breaker Rolling

Hot Forging – Closed Die

- Impression-Die Forging

- Flashless Forging

- Flash-Type Forging

- Precision Forging

Automotive Should Cost Models for Metal Fabricated Parts

- Fabrication – Sheet Metal

- Laser Cutting

- Shearing

- Press Brake Bending

- Punching & Notching

- Roll Forming

- Deburring & Finishing

Machining – Gear

- Gear Hobbing

- Gear Shaping

- Gear Grinding

- Gear Broaching

- Gear Heat Treatment

- Fabrication – Structural & Others

- Steel Beam & Plate Welding

- Pipe & Tube Spooling

- Chassis & Frame Assembly

- Sheet Lamination

Metal Hose Assembly

- Spiral‐Wound Hose

- Braid Reinforced Hose

- Corrugated Hose

- PTFE Lined Hose

- Swaging & End Fitting

Stamping – Progressive Die

- Multi-station Strip Feeding

- Cutting, Forming & Piercing

- Progressive Coil Processing

- Stamping – Transfer Die

- Individual Blank Feeding

- High-Speed Compound Operations

- Automated Part Transfer

Stamping – Compound Die

- Simultaneous Cutting & Forming

- Deep Draw & Embossing

- High-Tonnage Presses

Cutting & Ablation

- Laser Cutting

- Plasma Cutting

- Waterjet Cutting

- Oxy-Fuel Cutting

- Welding & Joining

- MIG / MAG Welding

- TIG Welding

- Spot Welding

- Friction Stir Welding

- Laser Welding

Surface & finishing

- Grinding & Polishing

- Powder Coating

- Anodizing

- Galvanizing

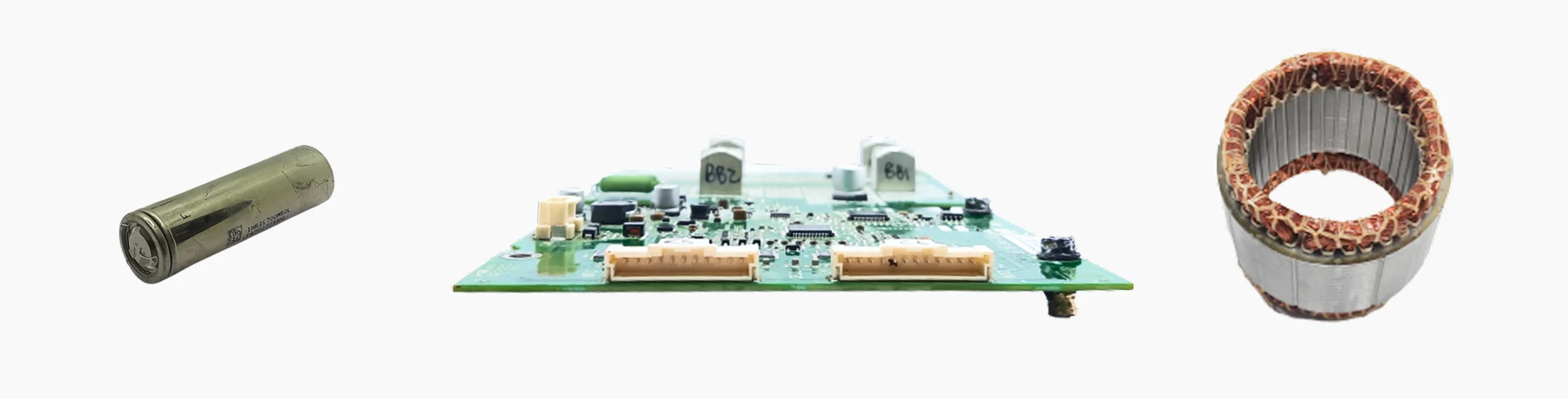

Should Cost Models for Electrical Components

- Connectors

- Wire-to-Wire Connectors

- Wire-to-Board Connectors

- Board-to-Board Connectors

- Terminal Blocks

- Automotive Sealed Connectors

Electrical Cable

- Shielded Power Cable

- Coaxial Cable

- Ribbon Cable

- High Voltage Cable

- EV Battery Cables

Cell

- Cylindrical Cell

- Prismatic Cell

- Pouch Cell

- LFP / NMC / NCA Chemistries

- Cell Terminal Configurations

Display

- LCD Panel

- LED Backlit Display

- OLED Display

- Touch Panel (Capacitive / Resistive)

- TFT Module

- PCB – Aluminium

- Single Layer Aluminium PCB

- IMS (Insulated Metal Substrate)

- High Thermal Conductivity Types

- LED Application Boards

PCB – Copper

- Heavy Copper PCB

- High Frequency PCB

- Multilayer Copper Core

- RF Power PCBs

PCB – FR4

- Standard FR4 PCB

- Multilayer FR4 PCB

- Rigid-Flex FR4

- High Tg FR4

PCB – Ceramic

- Alumina Ceramic PCB

- Aluminium Nitride PCB

- Direct Bonded Copper (DBC)

- Low-Temperature Co-fired Ceramic (LTCC)

- PCB – Flexible

- Single-Sided Flex PCB

- Double-Sided Flex PCB

- Rigid-Flex PCB

- Polyimide Substrate

Bare PCB – 1 Layer

- FR4 / CEM1

- HASL Finish

- Basic Copper Thickness

Bare PCB – 2 Layer

- FR4 / Aluminium

- Via Drilling

- ENIG / OSP Finishing

Bare PCB – 4 Layer

- Signal-Ground-Signal-Ground Stackup

- Controlled Impedance

- Via-in-pad Design

- Bare PCB – 6 Layer

- Power-Ground Separation

- High-Speed Signal Routing

- Blind & Buried Vias

Bare PCB – 8 Layer

- Advanced Multilayer Stackup

- High-Density Interconnect (HDI)

- Thermal Management Layers

Stator

- Laminated Core Stator

- Hairpin Wound Stator

- Slotted vs Slotless Stator

- Die Cast Winding

Rotor

- Squirrel Cage Rotor

- Interior Permanent Magnet (IPM)

- Surface PM Rotor

- Wound Rotor Construction

Should Cost Models for Machined Parts

- Drilling

- Standard Twist Drilling

- Deep Hole Drilling

- Gun Drilling

- Pilot & Reaming

Tapping

- Hand Tapping

- Machine Tapping

- Blind Hole Tapping

- Thread Forming

Turning

- External Turning

- Facing on Lathe

- Grooving & Parting

- Thread Turning

Milling

- Face Milling

- Slot Milling

- Profile Milling

- End Milling

Threading

- Single-Point Thread Cutting

- Rolling Dies

- Thread Milling

- Facing

- Lathe Facing

- Plunge Facing

- Facing in Chuck Work

Broaching

- Internal Keyway Broaching

- External Surface Broaching

- Rotary Broaching

Grinding

- Surface Grinding

- Cylindrical Grinding

- Centerless Grinding

- Tool Grinding

Boring

- Line Boring

- Jig Boring

- Horizontal Boring

Notching

- Tube Notching

- Sheet Metal Corner Notching

- Angle Notching

- Laser Cutting

- Fiber Laser

- CO₂ Laser

- Pulse Laser for Microcutting

Honing

- Manual Honing

- Vertical Honing

- Plateau Honing (Automotive)

Gear Hobbing

- Spur Gear Hobbing

- Helical Gear Hobbing

- Spline Cutting via Hobbing

Gear Shaping

- Internal Gear Shaping

- External Gear Shaping

- Timing Gear Shaping

Gear Shaving

- Radial Infeed Shaving

- Diagonal Shaving

- Underpass Method

- Gear Grinding

- Profile Grinding

- Generating Grinding

- Form Grinding

Shot Blasting

- Steel Grit Blasting

- Wheel Blast Systems

- Shot Blast Cleaning

Shot Peening

- Air Blast Peening

- Gravity Peening

- Saturation Peening

Sand Blasting

- Suction Sandblasting

- Pressure Blasting

- Abrasive Media Selection

Lapping

- Flat Lapping

- Cylindrical Lapping

- Polishing and Final Finishing

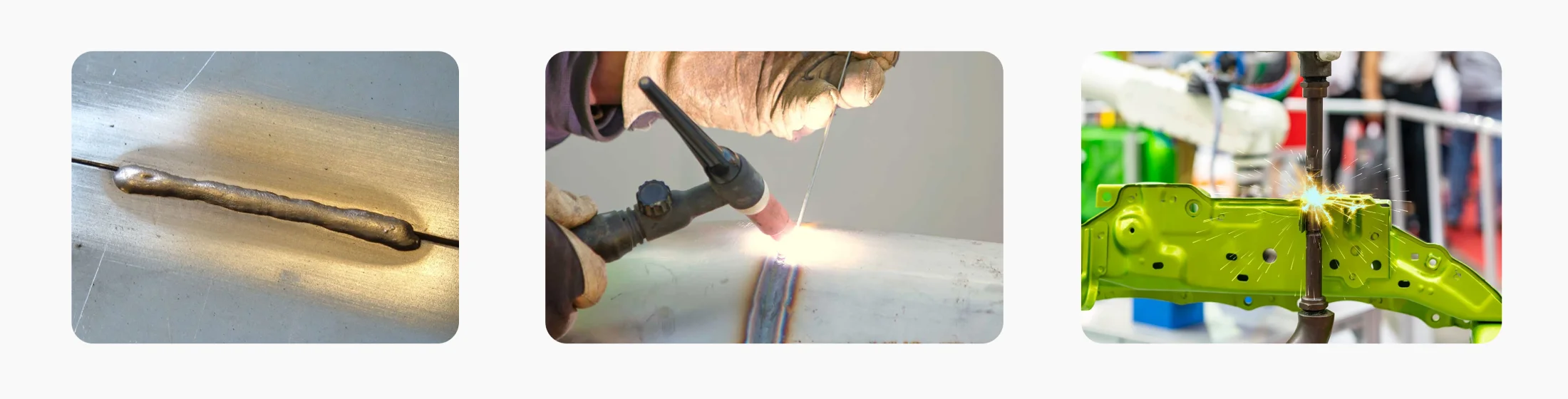

Automotive Should Cost Models for Welding & Joining

- MIG / MAG Welding

- Carbon Steel MIG

- Stainless MAG

- Pulse MIG for Aluminum

TIG Welding

- Manual TIG

- Orbital TIG

- Thin Section Welding

- Spot Welding

- Projection Spot Welding

- Cross Wire Welding

- Resistance Spot Weld

Friction Stir Welding

- Aluminum Profile Joining

- Tool Steel Weld Head

- Automated Linear FSW

- Laser Welding

- Keyhole Welding

- Conduction Welding

- Fine Micro-Welds

Ultrasonic Welding

- Plastic Ultrasonic Welding

- Wire Splicing

- Battery Tab Welding

- Riveting / Clinching

- Solid Riveting

- Blind Riveting

- Mechanical Clinching

Should Cost Models for Surface Finishing in xcPEP

- Powder Coating

- Epoxy Powder Coat

- Polyester Powder Coat

- Hybrid Powder Finishes

Electroplating

- Nickel Electroplating

- Zinc Plating

- Chrome Plating

- Anodizing

- Type II Color Anodizing

- Type III Hard Anodizing

- Clear & Black Coatings

Galvanizing

- Hot-Dip Galvanizing

- Electrogalvanizing

- Dry Coating Post-Galv

- Passivation

- Citric Acid Passivation

- Nitric Acid Process

- Stainless Steel Surface Prep

- Deburring & Polishing

- Tumbler Finishing

- Vibratory Deburring

- Buffing & Brushing

Should Cost Models for Testing & Inspection Process in xcPEP – Should Cost Analysis Tool

- Dimensional Inspection

- CMM Inspection

- Height Gauge / Vernier

- Go/No-Go Gauge

Visual Inspection

- Manual Surface Check

- Visual Defect Sorting

- Deflash / Burr Check

- X-Ray & CT

- Die-Cast Void Inspection

- Battery Cell CT Scan

- BGA Package X-Ray

- Hardness & Microstructure

- Rockwell / Vickers Testing

- Metallographic Etching

- Grain Size Analysis

- Leak & Pressure Testing

- Helium Leak Test

- Air Decay Test

- Hydrostatic Pressure Test

Should Cost Models for Automotive Packaging & Logistics in xcPEP – Cost Analysis Platform

- Export Packaging

- Palletized Crates

- Heat-Treated Wood (ISPM 15)

- Heavy-Duty Shrink Wrap

Returnable Packaging

- Plastic Bin Systems

- Metal Returnable Cages

- Foldable Crates

- Thermoformed Trays

- Anti-Static Trays

- Custom Molded Cavities

- Conductive Tray Systems

- Labeling & Identification

- Barcode Printing

- Part ID & QR Labels

- Compliance Tagging (RoHS, REACH)

- Final Assembly Packing

- Subassembly Kits

- Cushioned Inserts

- Operator Instruction Leaflets

Automotive Miscellaneous Should Cost Models in xcPEP, should cost modelling software

- Booklet

- Saddle Stitch Binding

- Perfect Binding

- Wiro Binding

- Folded Leaflet Assembly

- UV Coating & Lamination

Composite

- Prepreg Layup

- Vacuum Bagging

- Resin Transfer Moulding (RTM)

- Autoclave Curing

- Filament Winding

- Fabric – Rexine

- Heat Embossing

- Pattern Cutting

- Stitching & Overlocking

- Surface Coating

- PVC/PU Backing Lamination

Glass Sheet Manufacturing

- Float Glass Process

- Annealing & Cutting

- Coating & Tempering

- Silk Screen Printing

- Mirror Backing Application

- Glass Moulding

- Press & Blow Moulding

- Injection Blow Moulding

- Rotary Moulding

- Hot Mould Preheating

- Annealing Tunnel Furnace

Paper Packaging

- Corrugated Box Forming

- Die Cutting & Slotting

- Folding & Gluing

- Printed Sleeve Application

- Pulp Moulded Tray

- Substrate – Ceramic

- Alumina Ceramic Substrates

- Green Tape Lamination

- Laser Scribing

- Firing & Metallization

- Direct Bonded Copper (DBC)

Wood

- Plywood Cutting

- Edge Banding

- Laminate Pressing

- Routing & CNC Machining

- Surface Polishing