Consumer Electronics Benchmarking & Cost Reduction

A teardown-led approach to find real savings

ASI Engineering performs a complete teardown of your product alongside a competing device to understand how each design and manufacturing choice impacts cost. Electrical and mechanical components are mapped in detail, and costed using real production logic inside xcPEP. This direct comparison reveals cost gaps and highlights specific opportunities to optimise material selection, simplify assemblies, and reduce process waste — all without compromising product quality.

Consumer Electronics

Benchmarking & Cost Reduction

Consumer electronics should costing is a cost engineering method used to determine the fair value of a product by analyzing the materials, labor, manufacturing processes, and overheads associated with all its parts. This includes electrical components such as printed circuit boards and each mounted element, as well as mechanical assemblies like housings, mounts, and enclosures.

With should costing, consumer electronics companies can identify cost reduction opportunities, benchmark competitors, negotiate more effectively with suppliers using detailed cost insights, accelerate development timelines, and make smarter sourcing decisions to stay competitive in a volatile and cost-sensitive market.

Teardown benchmarking

Of Customer's & Competitor's Vehicles

Should Costing

Of Customer's & Competitor's Vehicles

Cost Reduction Idea Generation

By analyzing cost gaps between customer's and competitor's vehicles.

Challanges and limitations of methods in -

Consumer Electronics Cost Reduction Studies

Many platforms that claim to support cost reduction are built only to compare bill of materials data. They focus on part-level price differences without understanding how those costs arise. These tools rely on supplier quotes, apply generic databases, and produce savings deltas that lack technical depth.

There is no teardown. Mechanical components are skipped, and assumptions are made from catalog values instead of real inputs. Key manufacturing factors like cycle time, tooling life, scrap, and regional overhead are left out entirely.

Without this context, there is no root cause clarity. The result is a list of surface-level suggestions that may look convincing in a slide but fail when tested in production. Engineering and sourcing teams need actionable ideas based on real manufacturing—not abstract comparisons.

You cannot reduce what you have not understood. True savings come only when every part is stripped down, costed correctly, and compared with its benchmark.

Electronics Should Costing in xcPEP

Every part is disassembled, mapped, and costed using actual process flow

How ASI Engineering Uses

xcPEP to Drive Savings

xcPEP is ASI’s proprietary cost engineering platform specifically built to convert detailed teardown insights into clear and actionable cost savings.

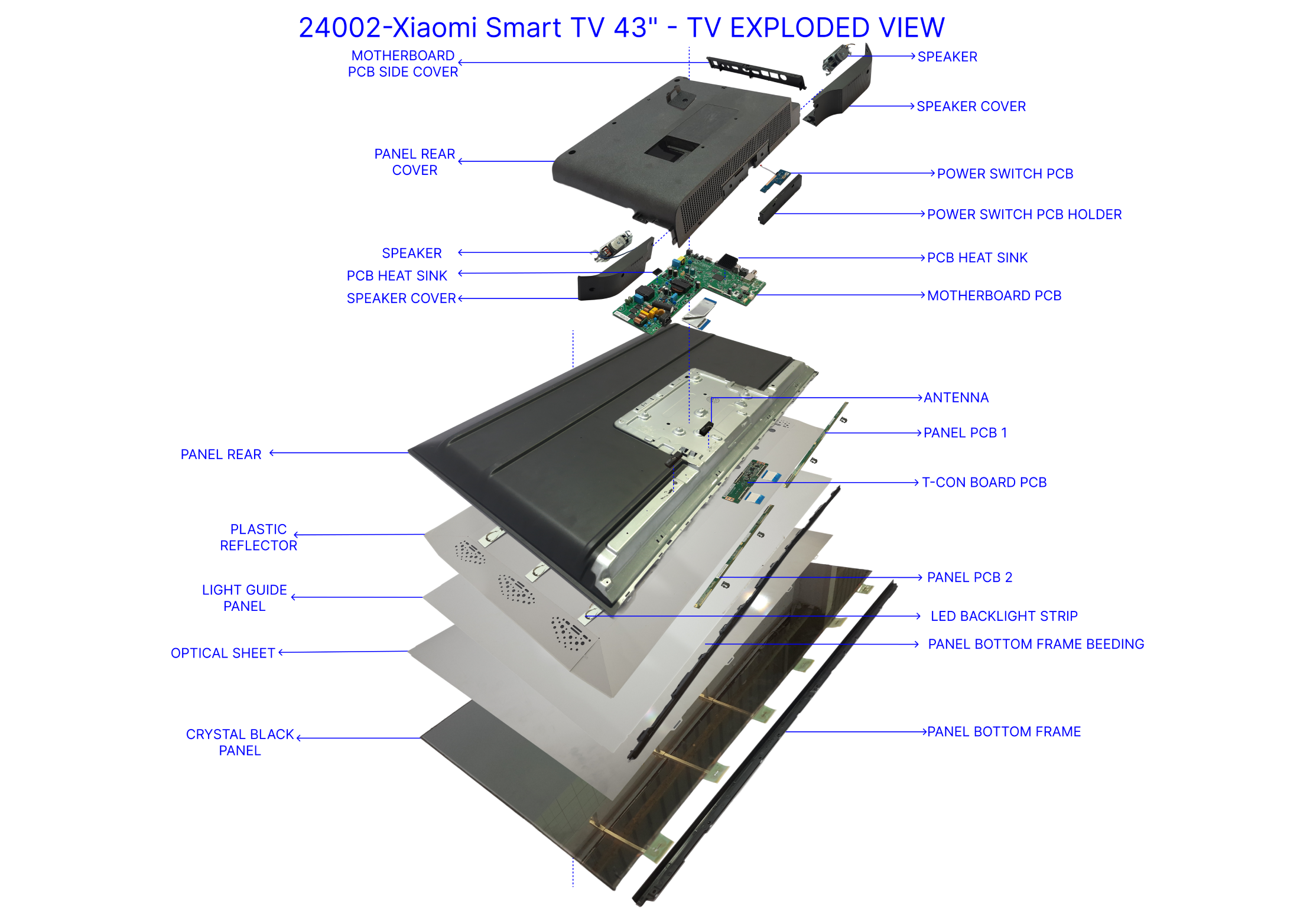

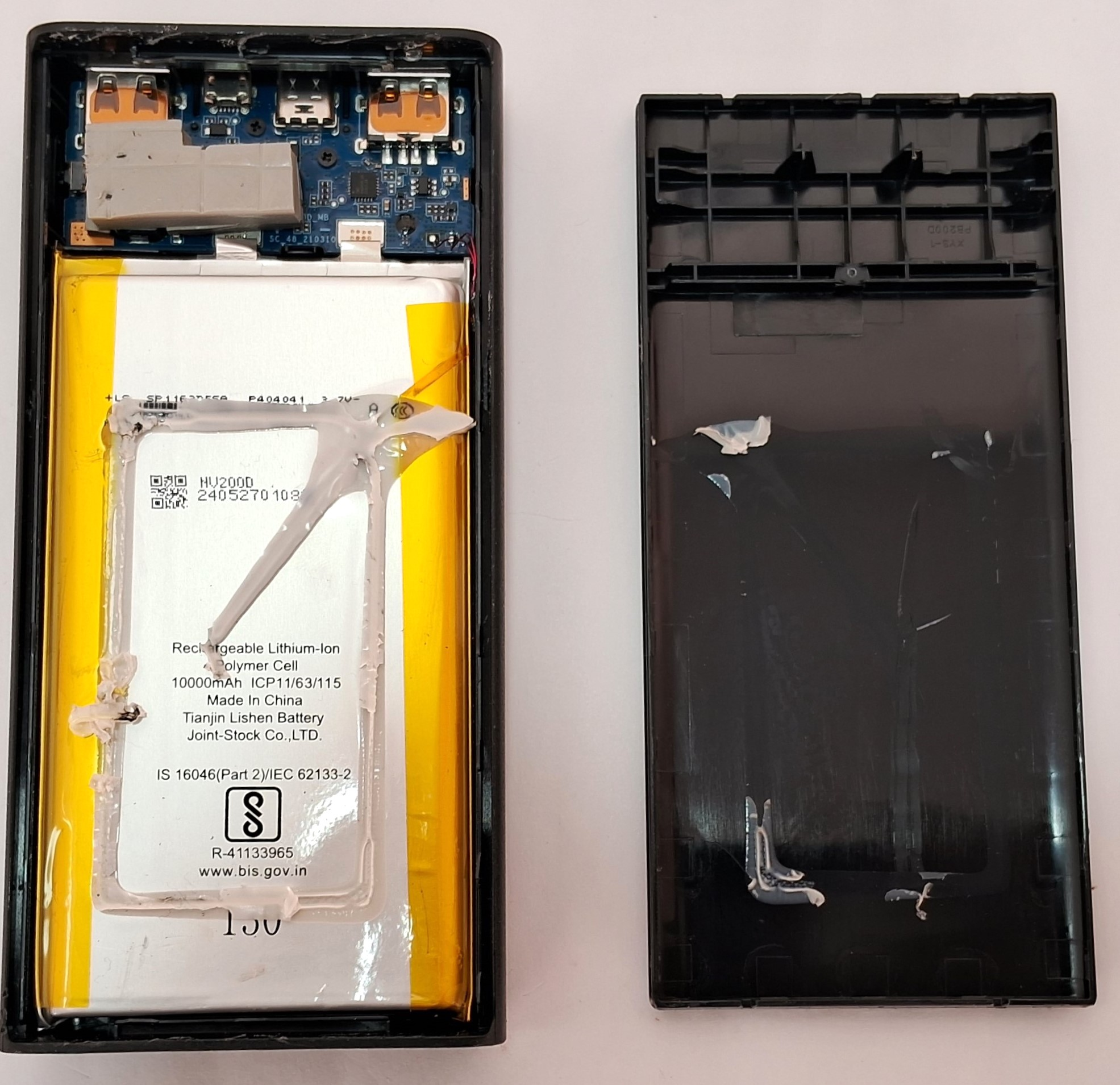

Every component inside a consumer electronics product, including complex PCBs, molded enclosures, connectors, buttons, and display modules, is analyzed and costed using precise manufacturing routes, real factory process logic, and validated region-specific data from xcPROC.

This structured, methodical approach enables engineering and sourcing teams to pinpoint exact cost reduction opportunities, validate supplier quotations with confidence, benchmark competitor products, and drive real cost savings at each stage of the product lifecycle.

By providing such granular insights, xcPEP ensures teams do not rely on assumptions, averages, or generic estimates, resulting in meaningful, measurable savings.

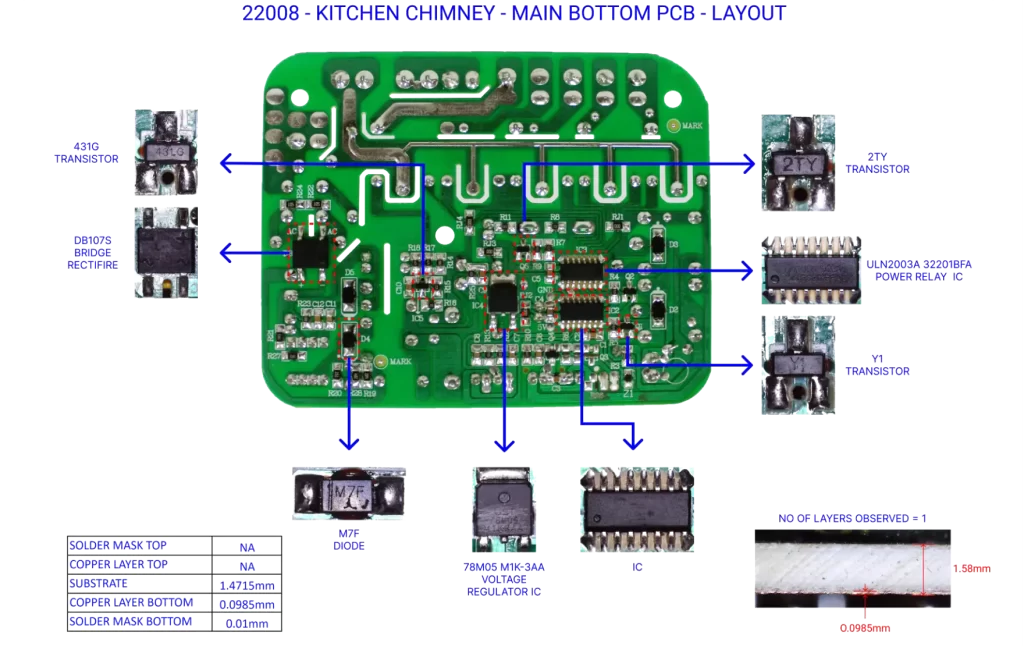

In depth costing of PCB

In depth costing of mechanical parts

Massive Library of Cost Models

ASI Engineering maintains a comprehensive library of validated cost models within xcPEP tailored specifically to consumer electronics. Teams quickly benchmark new designs or sourcing decisions against reliable models, accelerating the discovery of cost reduction ideas.

Precise Machine Database

ASI Engineering utilizes xcPEP’s integrated machine database, ensuring every costing study is based on real utilization rates and exact production data. This ensures cost reduction analyses reflect true manufacturing conditions, enabling confident negotiations with suppliers.

Scenario costing: Easily shift PCB sourcing from China to India

ASI Engineering employs xcPEP’s scenario costing functionality to instantly compare different sourcing scenarios, such as shifting PCB production from China to India. Teams can quantify the exact cost impact, enabling informed decisions to optimize sourcing strategies and reduce supply chain costs.

In depth data analysis for cost savings

ASI Engineering provides structured and detailed cost analyses through xcPEP, going beyond simple averages. Granular insights on every part and manufacturing step enable teams to proactively identify previously hidden cost reduction opportunities.

The captured data flows directly into xcPEP, where it enables side by side cost comparison between your product and competing devices. This structured input allows ASI Engineering to trace cost differences back to design, packaging, or layout choices and generate specific, actionable ideas to reduce cost while maintaining product performance.

xcPEP

xcPROC

Comprehensive and Detailed Data Mapping

By leveraging machine learning models built in xcPEP

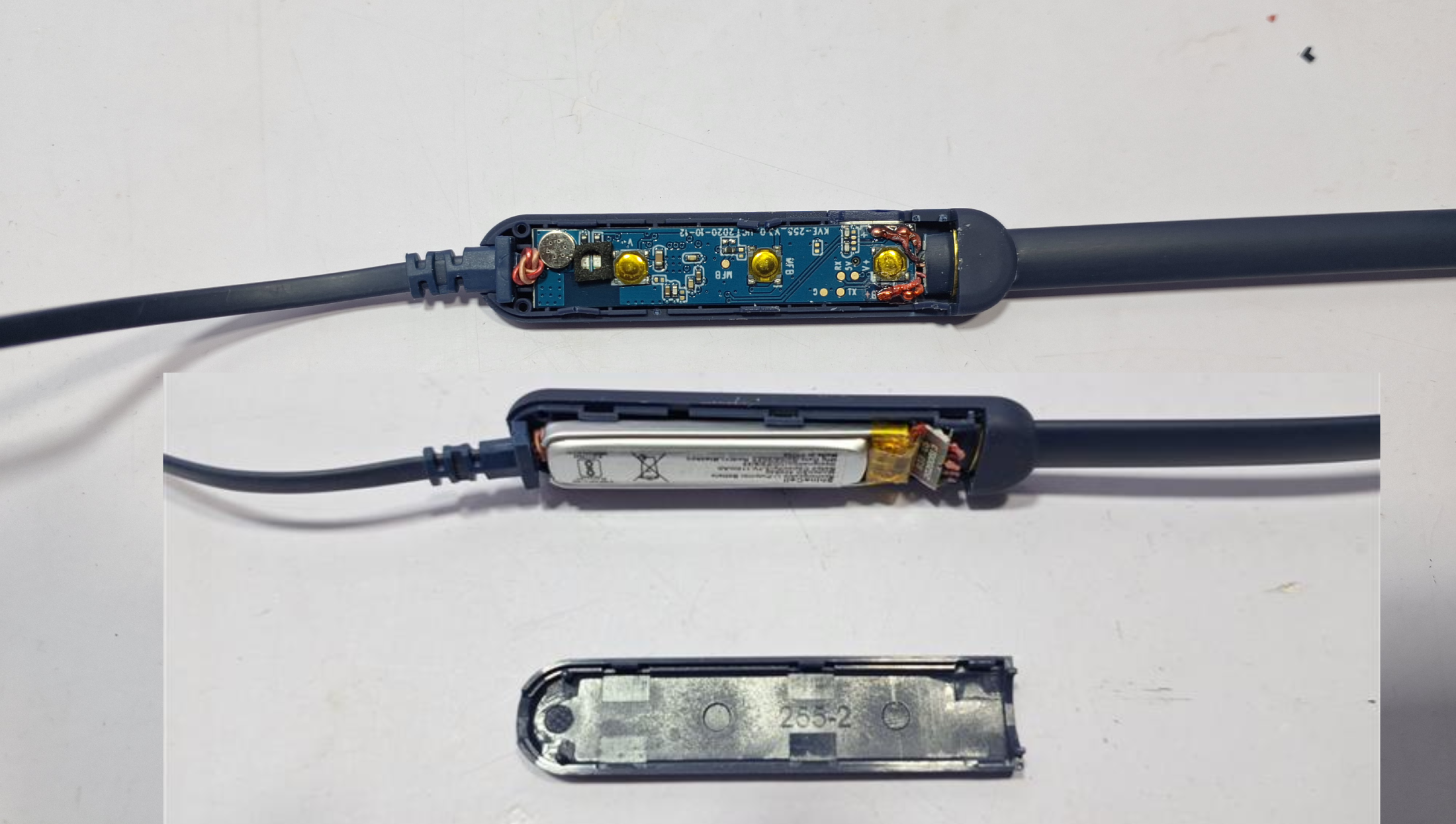

ASI Engineering uses purpose-built tools developed in house to support fast and structured teardown of consumer electronics products. These systems are designed to extract part level physical and geometric data such as bounding box dimensions, projected surface area, and PCB component details without relying on manual measurement or visual approximation.

The captured data flows directly into xcPEP, where it enables side by side cost comparison between your product and competing devices. This structured input allows ASI Engineering to trace cost differences back to design, packaging, or layout choices and generate specific, actionable ideas to reduce cost while maintaining product performance.

Detailed Data Mapping of -

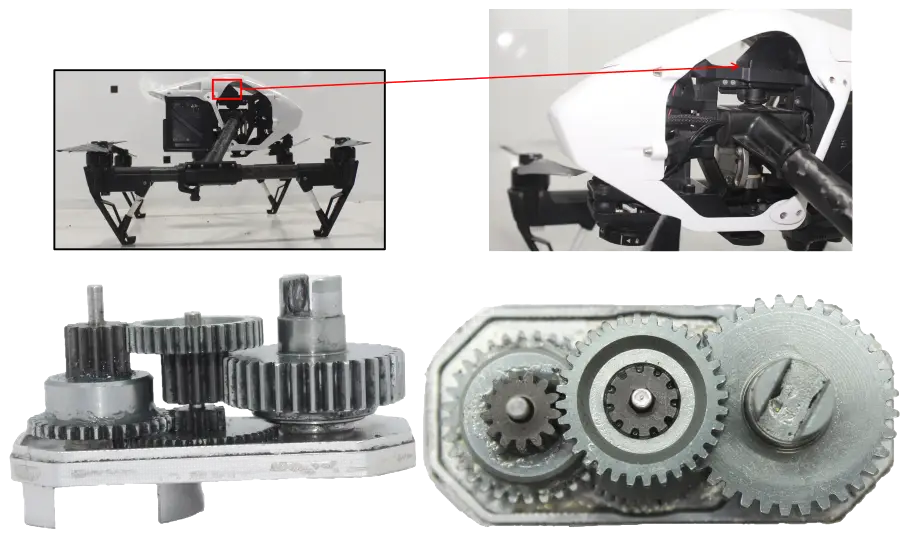

Mechanical Components

For mechanical parts in consumer electronics, ASI Engineering captures detailed physical data during teardown to help identify cost saving opportunities. To speed up this process and ensure consistency, we use in house tools like the Bounding Box Dimension Capture System and the Projected Area Capture System. These help us quickly collect size and shape data across parts like frames, housings, and brackets. This data is then used inside xcPEP to compare your product with a competitor and find which design or geometry choices are adding unnecessary cost.

Detailed Data Mapping of -

Electrical Components

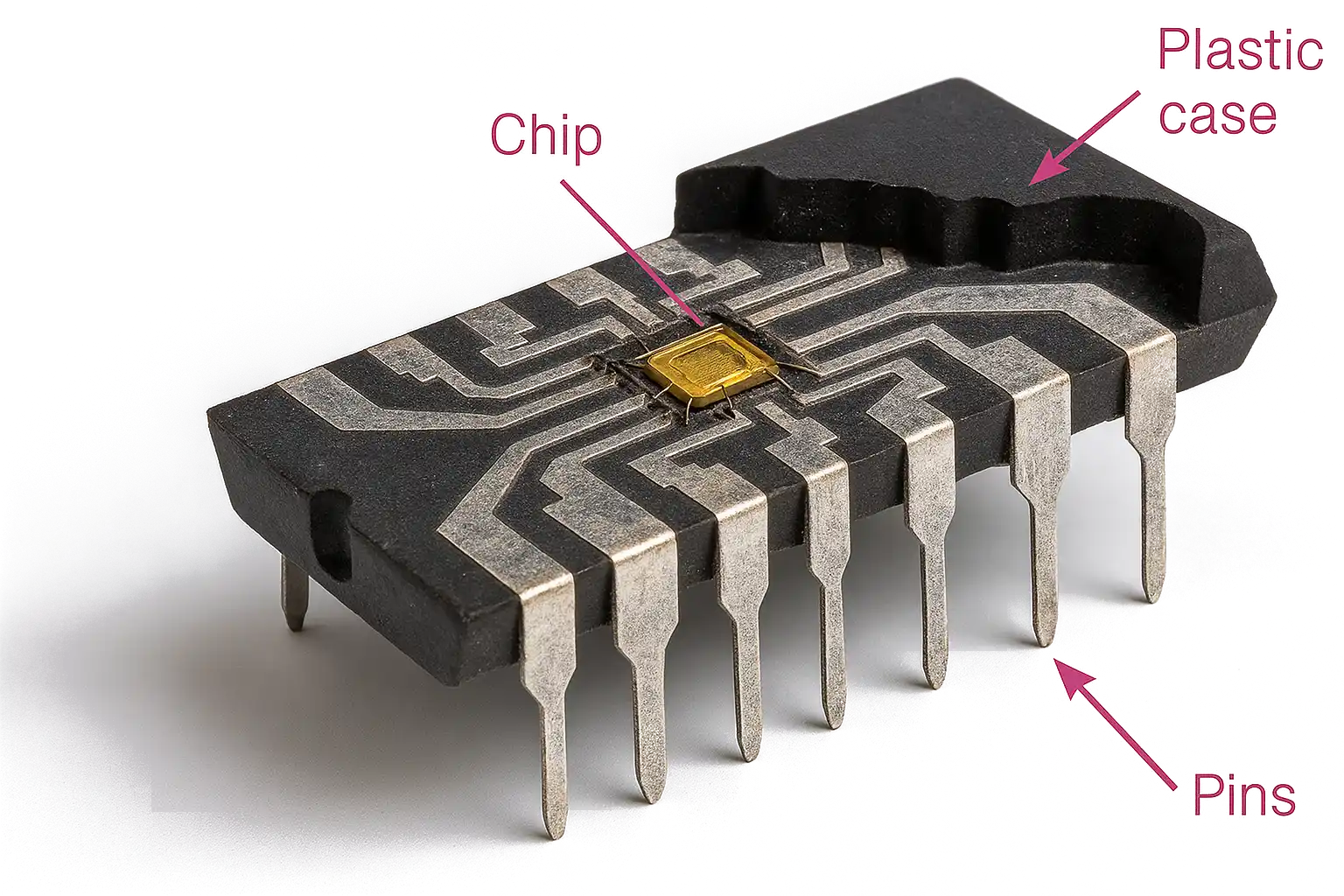

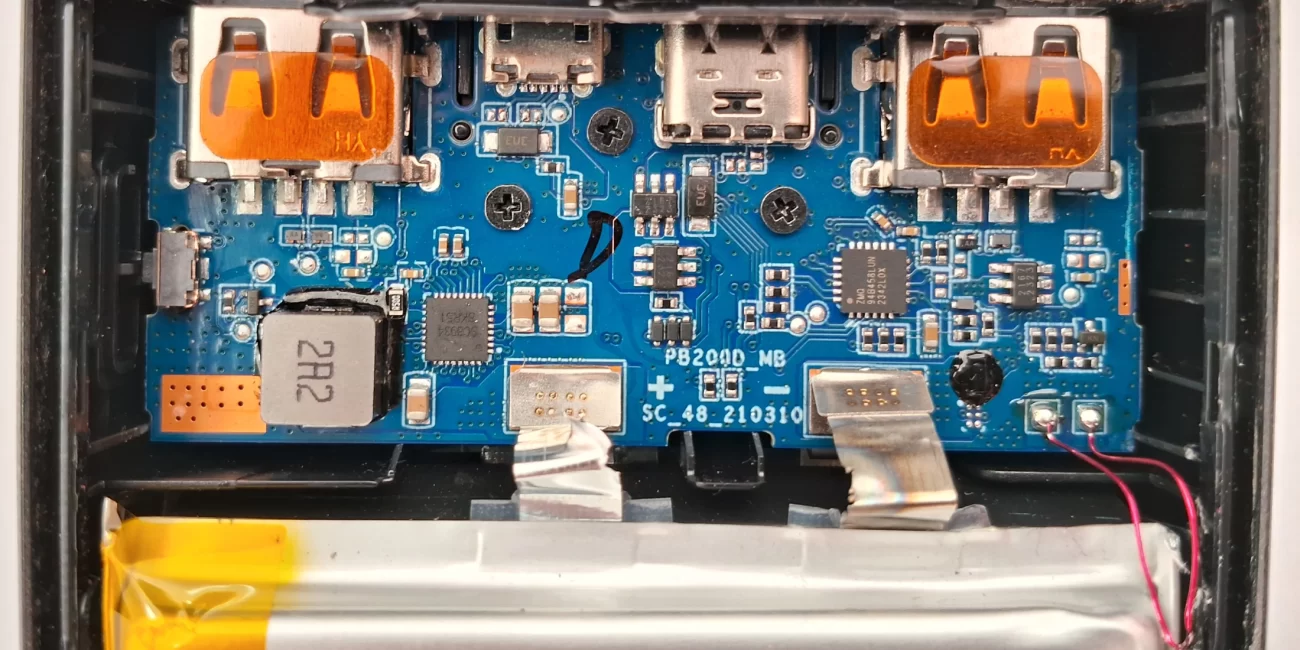

To support cost reduction in consumer electronics, ASI Engineering uses AI-based imaging tools to capture part-level data from PCBs with speed and accuracy. These tools automatically identify and classify every mounted component — including ICs, resistors, capacitors, and connectors — without relying on drawings or manual input. Each component’s placement, count, and type are processed into xcPEP, where the data is matched with sourcing rates and process parameters.

This allows us to build structured, evidence-backed BOMs that show where your design adds cost compared to a benchmark. Whether the goal is to simplify a control board, reduce component count, or switch to better value packages, the captured data helps teams take clear, cost-saving actions without slowing down development.

Cost Reduction Idea Generation in xcPEP

Software & Data Driven

Costing of Own Product

ASI Engineering uses xcPEP to cost your own product precisely, creating a clear baseline to spot savings.

Costing of Competitor Product

ASI Engineering benchmarks competitors using xcPEP, quickly revealing areas where competitors have lower costs.

Idea Generation by Comparison

ASI Engineering uses xcPEP to compare your product with competitors and identify actionable cost savings opportunities.

Engineering channels for cost reduction ideas

using xcPEP

Decontent

Alternate Material

ASI Engineering leverages xcPEP to evaluate and quantify potential savings from using alternate materials. The platform clearly compares material costs, processing differences, and overall impact on manufacturing, providing confident justification for material changes.

Alternate Supplier

With xcPEP, ASI Engineering quickly evaluates the cost impact of changing suppliers. By directly comparing detailed production costs across different regions and suppliers, teams can clearly see cost advantages, enabling better-informed sourcing decisions.

Alternate Manufacturing

ASI Engineering leverages xcPEP to simulate alternative manufacturing methods. The platform shows exact cost impacts, enabling informed decisions to optimize production methods.

Routing & Packaging

xcPEP helps ASI Engineering identify cost savings in packaging and logistics by simulating alternate routing options. Teams gain clear insights to simplify processes and reduce overall costs.

Knowledge transfer workshop

With your engineers and managers at your premises

How are we different?

Most BOM tools only manage child part costs and lack real manufacturing process costing. Management consultants rely on experience but miss data-driven accuracy.

xcPEP + ASI Engineering combines advanced software and expert engineering to deliver detailed costing for electrical, electronics, and mechanical parts. Our platform automates benchmarking and idea generation using real production data, giving you actionable and precise cost insights — not guesses.

Column Title

BOM based tools

Management Consultants

xcPEP + ASI Engineering

Technology for electrical parts costing

Technology for electronics parts costing

Technology for mechanical parts costing

Child part BOM cost management

Manufacturing process detailed costing

Overhead detailed assumptions

Automated data mapping for benchmarking

Experience based idea generation

Data based comprehensive idea generation

Product Studies

This section presents cost engineering projects carried out entirely by the ASI Engineering team. Every teardown, image, and cost model featured here is based on ASI’s own independent work. We focus on creating transparent, structured cost models that reflect real manufacturing logic.

Our studies cover a broad spectrum of consumer electronics, including smartphones, wearables, chargers, and display modules. These demonstrate how clean data and grounded assumptions produce cost insights that are clear, robust, and defensible. All models are built using actual process flows and assembly logic from real production.