Kitchen Chimney Teardown & Should Costing

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publishing.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

Explore xcPROC →

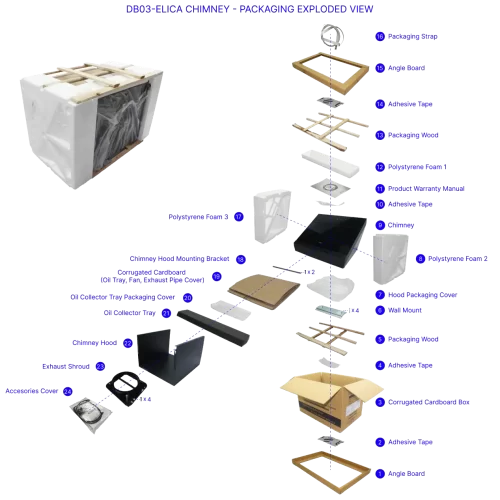

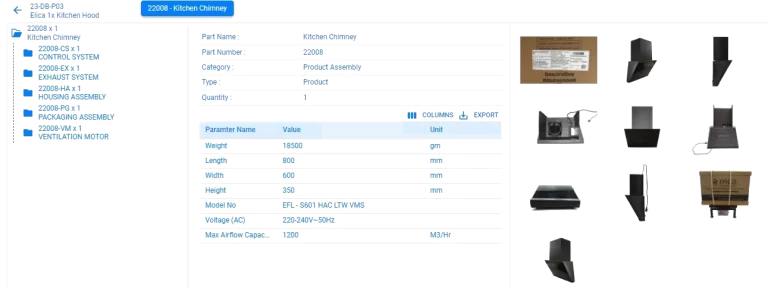

Exploded View of Elica EFL-S601 HAC VMS Chimney

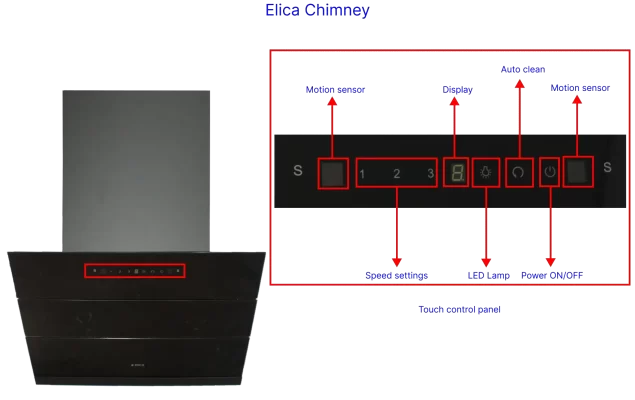

Features of ELICA KITCHEN CHIMNEY EFL - S601 HAC LTW VMS

1. Filter less Technology

2. Gesture Control

3. Heat Auto-Clean Technology

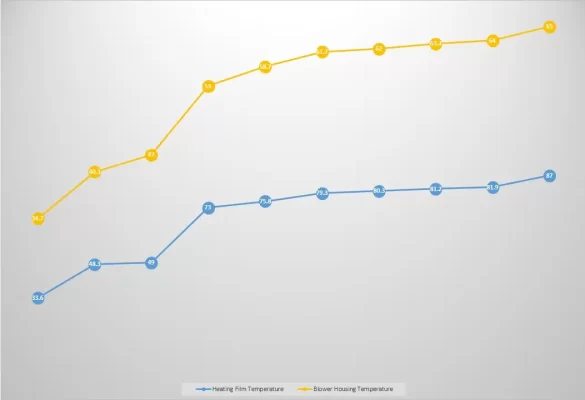

Heating Film : The Elica kitchen chimney incorporates a heating film as a key component in its design. The primary purpose of the heating film is to activate the auto clean function of the chimney. When the auto clean button is pressed on the control panel, the heating film is energized, generating heat. This heat is then transferred to the surrounding metal frame.

The elevated temperature of the metal frame helps to melt and dissolve the sticky oil particles that may have accumulated inside the chimney during cooking. The heating film effectively aids in breaking down and removing these oil deposits, improving the overall cleanliness and performance of the chimney.

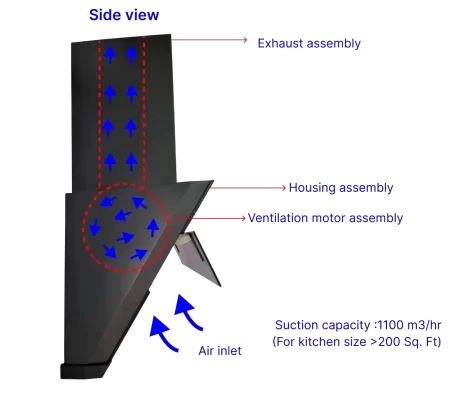

4. Maximum Suction Capacity

EFL-S601 HAC VMS Chimney is designed with filter less technology that has a powerful suction capacity of 1100 cubic meters per hour.

At the core of the EFL-S601 HAC VMS Chimney’s performance is its motor power of 180 W. This robust motor enables the chimney to generate strong airflow and suction, effectively capturing and exhausting airborne contaminants. With its high motor power, the chimney can efficiently handle the demands of various cooking styles and eliminate smoke and odours quickly and effectively. The combination of the filter less technology and the powerful 180 W motor power ensures optimal performance without the need for traditional filters.

5. LED Lights

6. Touch Controls

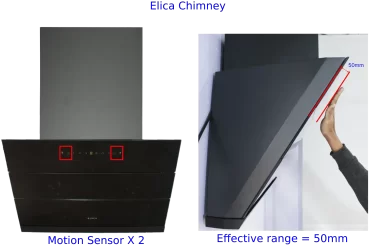

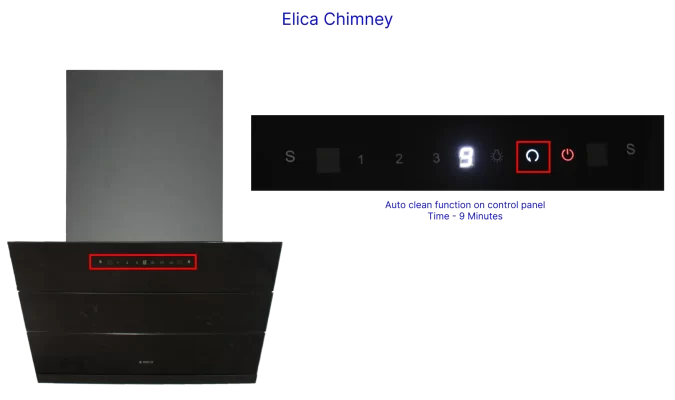

The Elica chimney features a convenient touch control panel located on the top front glass panel. This user-friendly interface allows easy access to various settings and features, enhancing the overall user experience.

At the centre of the touch control panel, a rectangular display is provided. This display serves as an information hub, providing real-time feedback and important details to the user. It prominently shows the current operating speed setting, allowing users to easily monitor and adjust the ventilation power according to their needs.

Architecture Diagrams

In the field of home appliances engineering, a thorough understanding of the packaging, overall construction, and functioning of the device is essential for successful development and deployment. To achieve this understanding, an architecture study was conducted, resulting in the creation of 19 diagrams that comprehensively categorize the various aspects of the Kitchen Chimney. These diagrams include the following:

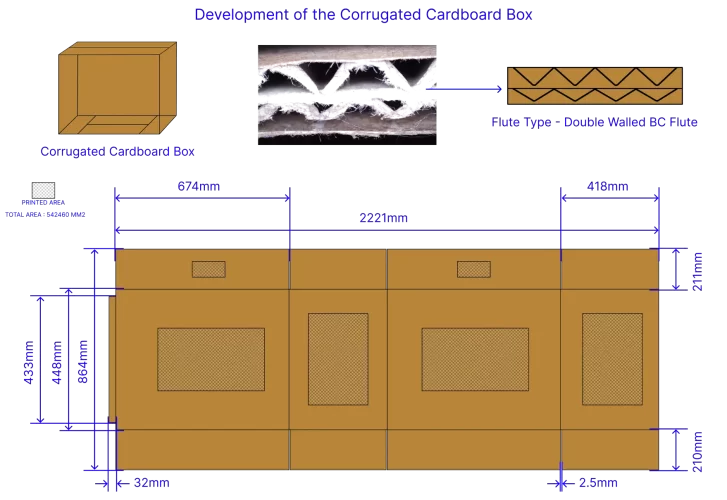

- Packaging diagram, which details the mounting of all the chimney’s parts and their key dimensions.

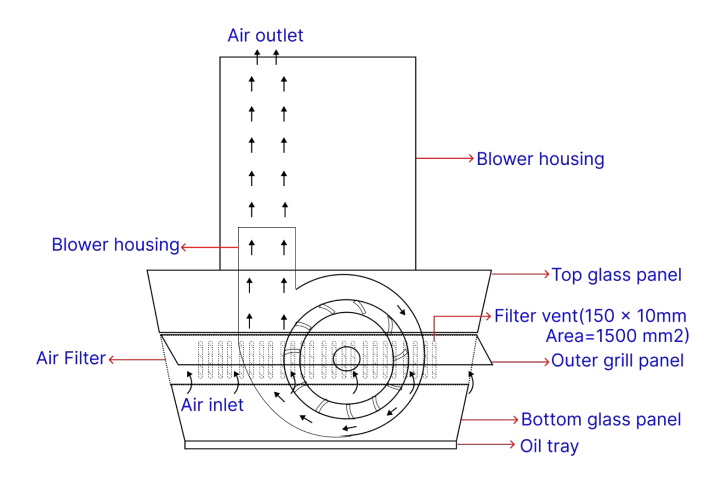

- Layout diagram, which depicts the internal layout of the chimney’s components, such as the motor, blower, and filters.

- Functional diagram, which provides insight into the functioning of the chimney’s features, such as suction power and airflow direction.

Packaging Diagram

The Elica kitchen chimney boasts a compact design, with dimensions measuring 785 mm in length, 600 mm in width, and 345 mm in height. This space-saving construction allows for easy installation and integration into various kitchen setups.

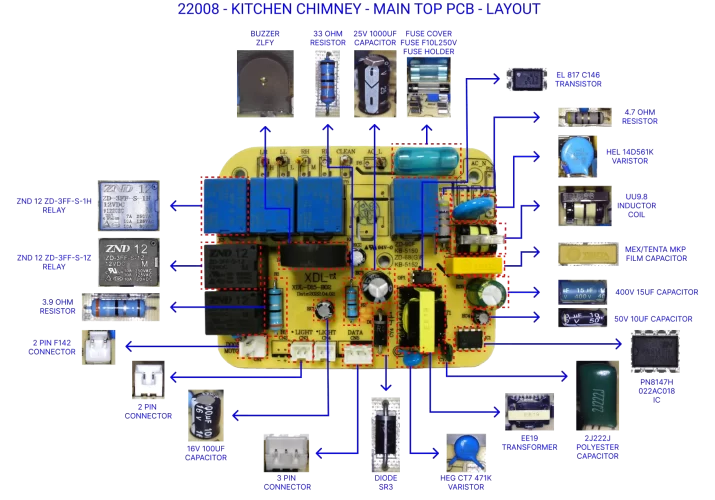

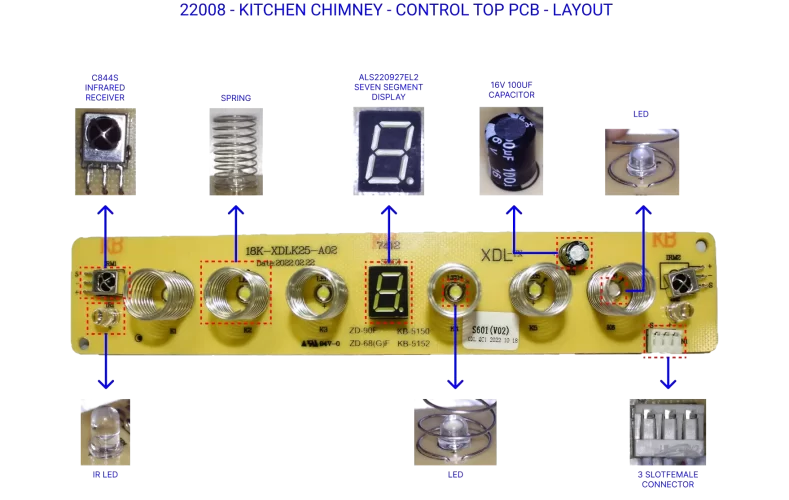

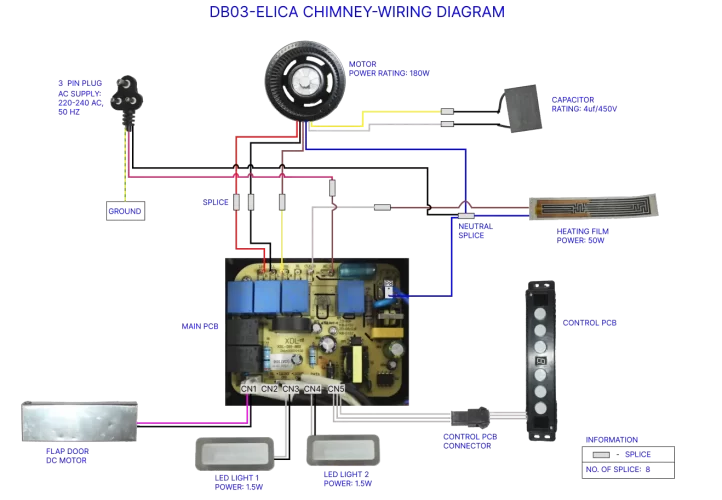

The chimney consists of two printed circuit boards (PCBs): a control PCB and a main PCB. These PCBs serve as the control and processing units, ensuring efficient operation and managing the various features of the chimney. The PCBs are securely enclosed in plastic boxes, safeguarding them from dust, moisture, and other potential hazards. This protective enclosure ensures the longevity and reliability of the electronic components.

Housed within a black colour powder-coated cold rolled steel housing and tempered glass, the Elica kitchen chimney offers durability and an aesthetic appeal. The sturdy steel housing provides robust protection for the internal components, while the tempered glass adds a touch of elegance to the overall design.

A heating film is glued and bolted to the blower fan casing. This heating film is responsible for activating the auto clean feature, which effectively removes sticky oil particles that may accumulate inside the chimney over time.

In order to gain a comprehensive understanding of the packaging process and associated costs of the Elica kitchen chimney, an exploded view of the packaging has been created. This view provides an overview of how the product is packed from the manufacturing unit to the customer’s end.

To facilitate this analysis, a detailed Bill of Materials (BOM) has been prepared, outlining all the packaging items required for the Elica kitchen chimney. This includes materials such as cardboard boxes, foam inserts, protective films, and other components used in the packaging process.

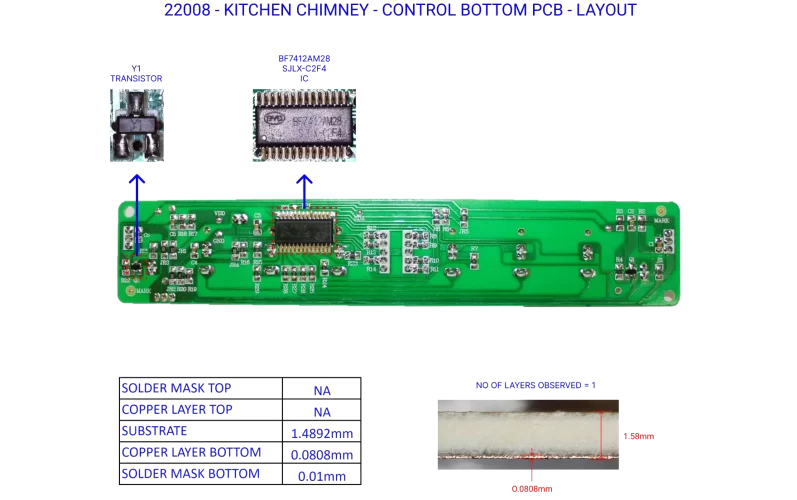

Layout Diagram

The Elica kitchen chimney comprises two main printed circuit boards (PCBs) and one LED PCB, collectively containing approximately 157 electronic components. These components encompass a variety of elements such as integrated circuits (ICs), relays, and other electronic devices.

To provide a comprehensive understanding of the component layout and their respective positions, accompanying diagrams have been created. These diagrams visually depict the arrangement of the electronic components on the PCBs, highlighting their specific locations and orientations.

Furthermore, the diagrams also include specifications of the electronic components used in the Elica kitchen chimney. This information provides detailed insights into the characteristics and functionality of each component.

Functional Diagram

The power button serves as the main control for the Elica kitchen chimney system. When pressed, it turns on the system, activating the various functions. Initially, the ventilation motor remains off, but the motor controlling the motion of the flap is turned on simultaneously. This allows for proper airflow control.

The system offers three speed settings for the ventilation motor. The speed adjustment is achieved by switching ON/OFF relays. When the corresponding speed switch is pressed, a signal from the control PCB is sent to the main PCB. The controller on the main PCB then activates the corresponding relay, which energizes the specific stator winding of the motor for the desired speed adjustment.

The speed control feature can be operated using two different methods. The control PCB can be operated via touch switches, with each switch corresponding to a specific speed setting. Alternatively, there are two non-contact IR sensors placed at the ends of the control PCB. By waving from left to right, the sensors detect the motion and increase the speed, while waving from right to left produces the opposite effect.

The Elica kitchen chimney also includes two LED lights, which can be controlled using a touch switch located near the power button. This allows users to easily adjust the lighting according to their preferences.

Furthermore, the system features an Auto Clean button on the control panel. When pressed, a heating film attached to the metal frame heats up. This heat melts the oils and impurities attached to the chimney’s internal cavity, ensuring effective cleaning. The melted oils and impurities are then drained onto a provided tray, which can be manually removed for disposal.

Ventilation Motor

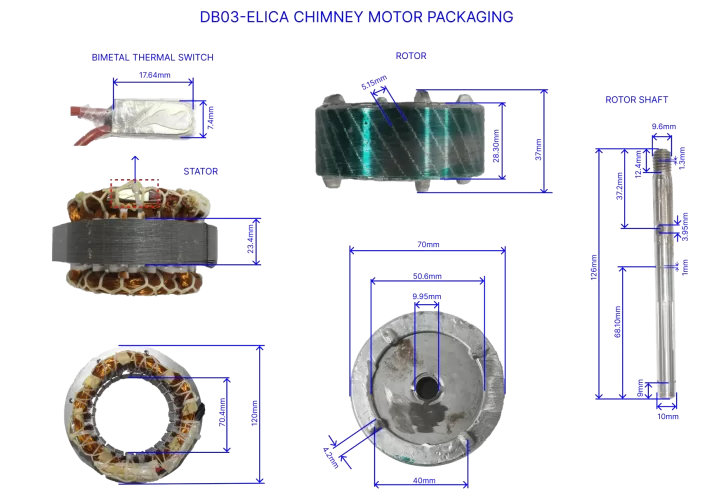

The ventilation motor utilized in the Elica kitchen chimney is a single-phase, three-speed squirrel cage induction motor. This motor is specifically designed to meet the requirements of the chimney’s ventilation system, providing efficient airflow control.

The motor is connected to a fabricated cold rolled steel metal blower, The blower is carefully designed to optimize the extraction of smoke, odours, and other airborne particles from the kitchen environment. To ensure the motor’s protection and durability, it is enclosed in a metal housing. This housing provides a robust and secure environment for the motor, safeguarding it from external elements and preventing any potential damage or interference.

Single phase – 3 Speed Squirrel Cage Induction Motor

The Elica kitchen chimney incorporates a single-phase squirrel cage induction motor with a power rating of 180 watts. This motor is specifically designed to operate at three different speeds, providing flexibility and control over the ventilation system.

The squirrel cage design is a common configuration for induction motors, known for its robustness and reliability. It consists of a rotor with short-circuited conductors resembling a squirrel cage, which interacts with the rotating magnetic field produced by the motor’s stator. Because the squirrel cage rotor has no winding, the rotor needs no maintenance, low noise and high reliability.

Construction

In the construction of the rotor core for the Elica kitchen chimney’s single-phase, three-speed squirrel cage induction motor, rotor punching is carried out using progressive stamping. These rotor laminations are then subjected to a steam bluing process. This process serves two purposes: it relieves the stress that may have developed during the punching operation, and it provides a bluish anti-corrosive coating to the laminations.

After the lamination process, the plates are intentionally twisted or skewed by one tooth pitch. This skewing technique helps to reduce magnetic noise and vibrations during motor operation, resulting in smoother and quieter performance.

A Bimetal Thermal switch is used for overheat protection.

Bill Of Materials Study

Our engineering team has performed a comprehensive last-level teardown analysis of the Elica kitchen chimney. Through a meticulous bill of materials (BOM) study, we have systematically documented data on the various part attributes, providing detailed insights into the components of the chimney.

We map product level, sub-assemblies level and part details in very high detail leaving nothing to subjectivity. On the xcPEP platform, these data points are all interlinked which helps in analytics and inference drawing in real time. Parameters for a project are designed with the end objective and corresponding analysis in mind.

In order to a detailed analysis of the product, we have divided it into sub-assemblies and child parts. Child parts are created in xcPEP based on the manufacturing process categories. Part details like box dimensions, weight, Images, material percentage, and material grade are mapped in BOM.

Bom Data Mapping

Manufacturing Category Distribution Analysis.

Should Directional Costing of Elica Kitchen Chimney

- The Elica Kitchen Chimney is produced in Pune, Maharashtra.

- The study considered an annual volume of 30000 units.

- The latest material rates, labour hourly rates, and machine hour rates were used for the calculations, taken as of May.

- PCB Child parts are considered as bought out in bulk from spot buy sites like Digi key, Mouser Electronics.

- Indian Rupees (INR) currency is used for costing.

- Tool cost is assumed to be paid upfront by the OEM & the total cost of the tool is divided by total number of parts made in a year.

Outcome

The comprehensive cost analysis of the Elica Kitchen Chimney reveals a detailed breakdown of the manufacturing expenses. The raw material cost accounts approximately 32 % of the total cost. This includes the procurement of high-quality components, electronic parts, mechanical elements, electrical components, and other necessary materials for the chimney’s construction.

The process cost accounts for around 17 % of the total cost. This category encompasses expenses related to various manufacturing processes involved in the assembly and production of the kitchen chimney. It includes labour costs for skilled workers, operating costs of specialized machinery and equipment, and expenses associated with quality control measures to ensure superior product standards.

The overhead cost accounts approximately 12 % of the total cost. This category covers indirect expenses incurred during the manufacturing process, such as rent for the facility, utility costs, administrative expenses, maintenance and repairs, and other miscellaneous costs essential for supporting overall manufacturing operations.

High-Cost Parts