EV Battery Pack Teardown Study

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publishing.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

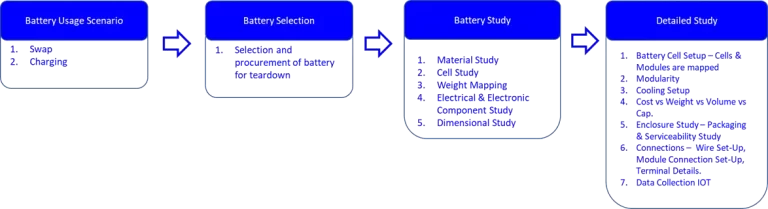

Explore xcPROC →We conduct detailed teardown study of electric vehicle battery packs typically for two purposes:

- Cost and engineering inputs for new product development.

- Cost reduction study of existing products by comparative teardown study.

Cost insights are generated to understand the cost drivers, supply chain strategies and metrics, commonality study and more. Engineering insights are generated for study or packaging, integration, interface with other subsystems and more.

Battery Pack detailed study

Schematics of the battery pack

EV battery module study

Modularity in packaging of battery pack

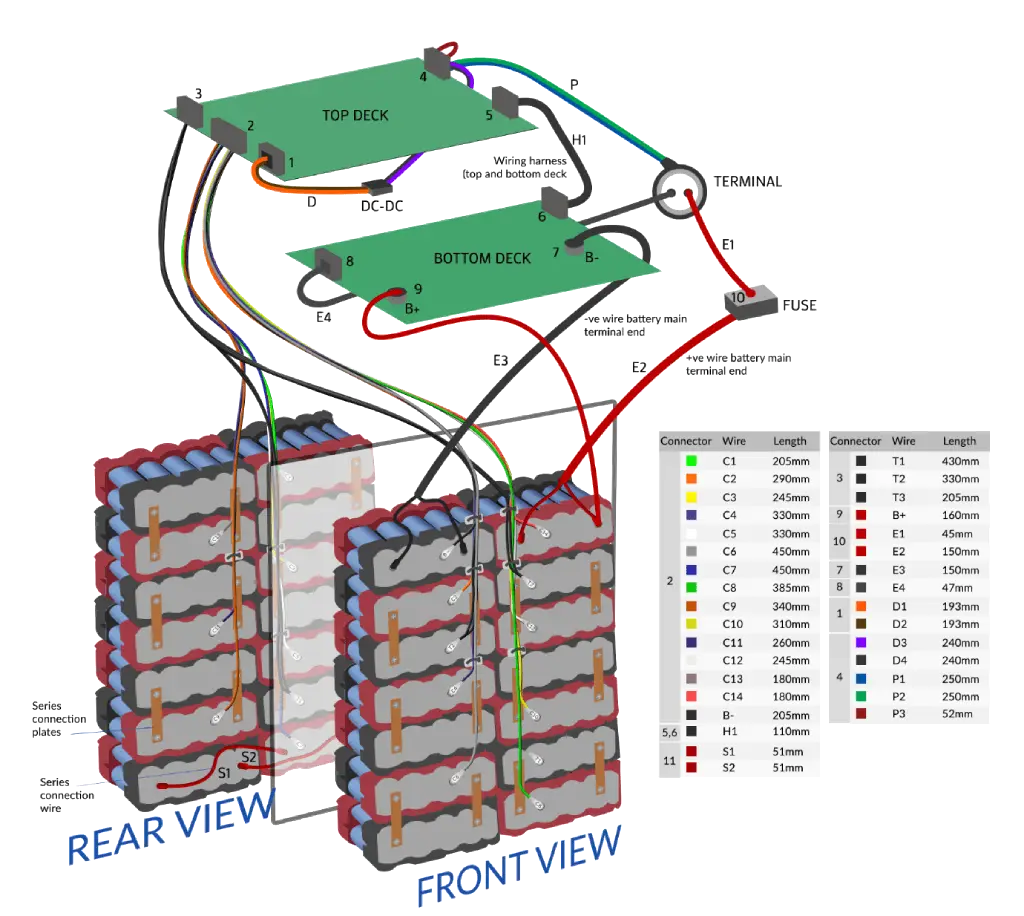

Connections & harness in the battery

Wire connections, Module connection setup and Terminal details are studied to understand the overall setup for voltage and current output battery is supposed to provide. This study also gives an understanding of the type of mapping BMS is providing on the battery modules based on connection layout.

Electrical Layout to be drawn for parallel and series.

PCB Protection is studied on benchmark battery pack to understand the type of exposure is expected and the type of protection available using PCB coating. This layer looks like a transparent polish over the board and its thickness is calculated in teardown to understand cost and procedure.

This type of layer mainly provides two benefits: –

- Saves the PCB board from corrosive elements and fluids and avoids failure due to humidity, corrosion, short circuits, etc.

- To provide higher electrical insulation for PCB’s own components which help in high voltage circuit.

BMS & electronics set-up

- BMS for following parameters is studied in the teardown parts based on PCB and connection study,

- Cell Balancing – this is studied based on the connections by understanding the module level and cell level connections to PCB/BMS board.

- Charging and Discharge Management – Connection study helps in understanding the charge/discharge protection availability, whether it is at cell level or module level.

- Circuit Protection provisions – type of switches- mosfets, etc.

- Data Storage – BMS stores the data points which are stored to use later for troubleshoot/check usage pattern.

- Other sensors used for thermal, impact and humidity mapping to save battery pack

- Type of controller chips and arrangements.

Sensors & data acquisition in EV battery

- Can be done using a memory card.

– In the existing battery memory card arrangement was used to store the data and during charging after battery swapping this data is being collected. - A GPRS/Bluetooth based system to send data to a server

– Data is sent to the server from battery automatically using GPRS or Bluetooth connection.

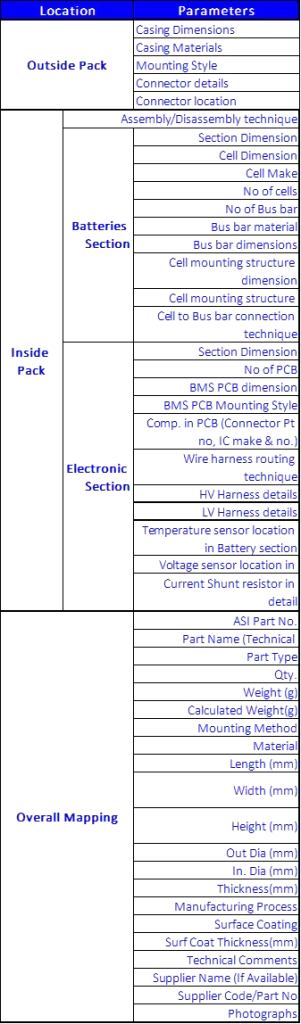

Enclosure study- safety and cooling of the battery

Each battery pack is dependent on mechanical, thermal and environmental factors to perform in its optimal range. Parameters studied for teardown to understand enclosure capability are: –

- Material grade for thermal performance

- Gap and vent availability around cells inside pack for flow.

- Vibration control provisions

- Shock/impact provisions

- Water resistance capability based on type of sealing.

- Serviceability and other mechanical functions in mind.

Enclosure is the critical part of battery pack as it provides the above-mentioned characteristic as well as has to provide spacing for wiring and cooling setup (fluid flow) inside the pack. Enclosure is designed in a way to support increase in battery cells without huge change in enclosure design and provides easy accessibility to PCB module for easy serviceability. In our example PCBs were connected in two layers with air gap to provide air cooling as well as arrangement in smaller space.