Catalytic Converter Benchmarking for Rare Earth Element Loading and Cost

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publishing.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

Explore xcPROC →

This blog is about the substrates used in catalytic converters their loading and more specifically focuses on the cerium-based catalytic ceramic substrates.

Catalytic converters are crucial emission control devices integrated into vehicle exhaust systems. They employ a combination of catalyst materials to facilitate the conversion of harmful pollutants present in exhaust gases into less harmful substances. Among the various types of catalytic converter substrates available, we have discovered that cerium-based substrates exhibit remarkable durability and efficiency in promoting the desired chemical reactions within the catalytic converter.

These cerium-based catalytic ceramic substrates offer several advantages over other substrates. They possess a high oxygen storage capacity, which aids in maintaining optimal catalytic activity. Furthermore, they enhance the catalytic activity itself, leading to more effective pollutant conversion. Additionally, these substrates demonstrate excellent resistance to sulphur, ensuring long-term performance and reduced emissions. Moreover, they exhibit exceptional thermal stability, further contributing to their overall effectiveness in emission reduction.

One notable advantage of cerium-based substrates is their cost-effectiveness compared to alternatives like rhodium, palladium, and platinum. The lower cost of cerium makes it an attractive option for catalytic converters, without compromising on performance or environmental benefits.

The primary objective of this blog is to present our study on the loading of rare earth metals, specifically cerium, in catalytic converters. We will delve into the methodology we employed to determine the optimal load of cerium in both the core and coating surface of the substrate. Furthermore, we will provide a detailed analysis of the should costing of the cerium-based substrate, shedding light on its economic viability.

Construction:

The ceramic substrate is designed with a honeycomb-like structure, consisting of numerous small channels or passages. These channels create a large internal surface area, allowing the exhaust gases to flow through the substrate while maximizing the contact with the catalyst.

The ceramic substrate is classified into three different types according to wall thickness: Standard (>0.13mm), thin-wall (<0.13mm and >0.10mm), and ultra-thin wall (<0.10mm). The substrate can be in a triangular, square, or hexagonal cell geometries.

Function:

Here is how a cerium-based ceramic substrate functions in a catalytic converter:

- Structure: The ceramic substrate in a catalytic converter is typically in the form of a honeycomb structure. It consists of many small parallel channels or passages. This honeycomb structure provides a high surface area for the catalyst materials to interact with the exhaust gases.

- Catalyst Coating: The coating of ceria (Cerium Oxide) on the ceramic substrate composition can enhance the catalytic activity of the converter. Ceria acts as a promoter, improving the efficiency of the catalyst in converting harmful pollutants into less harmful substances.

- Conversion of Pollutants: As the exhaust gases flow through the channels of ceramic substrate, the catalyst materials on the surface of the substrate facilitates various chemical reactions. The primary reactions include:<

- Oxidation of Carbon Monoxide (CO): The catalyst promotes the conversion of CO into carbon dioxide (CO2), which is less harmful.

- Oxidation of Hydrocarbons (HC): Unburned hydrocarbons in the exhaust gases are oxidized by the catalyst into carbon dioxide (CO2) and water (H2O).

- Reduction of Nitrogen Oxide (NOx): The catalyst facilitates the conversion of nitrogen oxides (NOx) into nitrogen (N2) and oxygen (O2), which are less harmful.

- Substrate Properties: The ceramic substrate provides several essential properties that contribute to the efficiency of the catalytic converter:

- Thermal stability

- High surface area

- Low pressure drops

Manufacturing:

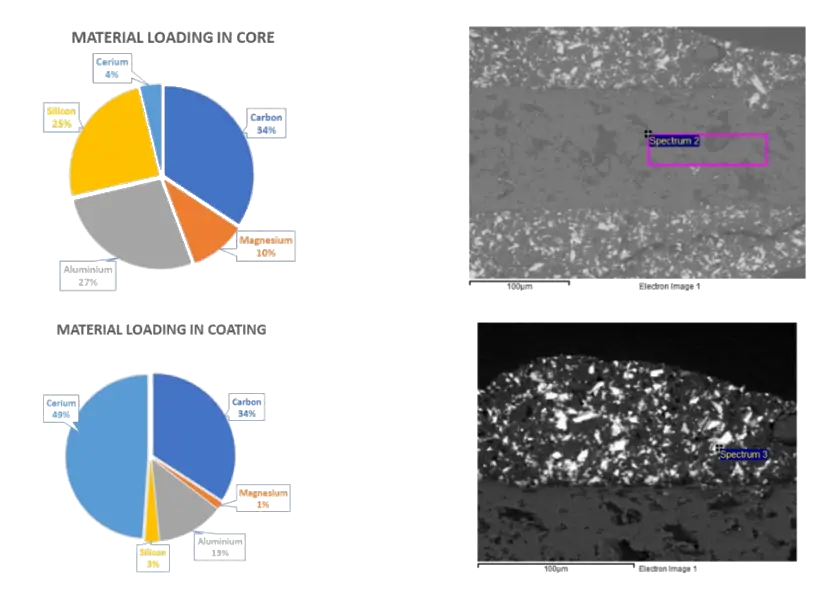

The ceramic substrate shown in Figure 1. is a ceramic monolith and is manufactured using extrusion process. The SEM (Scanning Electron microscopy) with EDM (Energy Dispersive X-Ray) test will be carried out on the ceramic substrate, from the test result we will get the material loading on the substrate. The manufacturing involves several steps listed below:

- Raw Material Preparation: The raw materials obtaining high-quality ceramic powders, such as alumina (aluminium oxide), magnesium oxide or silica can be used.

- Mixing: The ceramic powders are mixed with the binders (e.g., methylcellulose) and other additives. The mixing process ensures a homogenous distribution of the components and blended into a water-based uniform paste.

- Shaping: The mixed powder/paste is then shaped into the desired form with the extrusion process which involves forcing the mixture through a die to form continuous honeycomb structure.

- Drying: After shaping, the ceramic substrate is dried to remove any moisture and eliminate the binders. This can be done by air drying or using low-temperature ovens to prevent cracking or deformation.

- Firing/Sintering: The dried substrate is subjected to a high-temperature firing process known as sintering. Sintering causes the ceramic particles to bond together, resulting in a solid, dense substrate with improved mechanical strength and stability. The firing temperature and duration are carefully controlled to achieve the desired properties.

- Surface Preparation: After sintering, the ceramic substrate is prepared for the application of catalyst materials. This involves cleaning the surface to remove any impurities or contaminants that could interfere with the catalyst bonding.

- Catalyst Coating: Once the catalyst is applied, the substrate undergoes a catalyst activation step. This typically involves subjecting the coated substrate to high temperatures in an oxidizing or reducing atmosphere, depending on the specific catalyst materials used. The activation process helps transform the catalyst precursors into their active forms for efficient pollutant conversion.

- Catalyst Activation: The ceramic powders are mixed with the binders (e.g., methylcellulose) and other additives. The mixing process ensures a homogenous distribution of the components and blended into a water-based uniform paste.

- Quality Control and Testing: The quality control checks are conducted to ensure the ceramic substrate meets the required specifications. This includes dimensional measurements, visual inspection, and testing for mechanical, thermal, and catalytic properties. The final catalytic ceramic substrate may also undergo performance testing to assess their efficiency in reducing emissions.

Figure 3: Ceramic monolith and the catalyst wash-coat thickness.

Should Costing:

Should costing (SC) of a cerium-based ceramic catalytic substrate involves analyzing and determining cost elements, including material costs, manufacturing process expenses, quality control, overhead costs, packaging, logistics, and profit margin. The costing outcome is solely depended on the region of manufacturing and production volume of the substrate. For costing we will consider standard ceramic substrate shown in Figure 1. There are four aspects taken into consideration: assumptions , material cost, manufacturing process cost, and overheard cost.

- Assumptions: The substrate is manufactured in Hosur, Tamil Nadu with annual volume of 40,000 units.

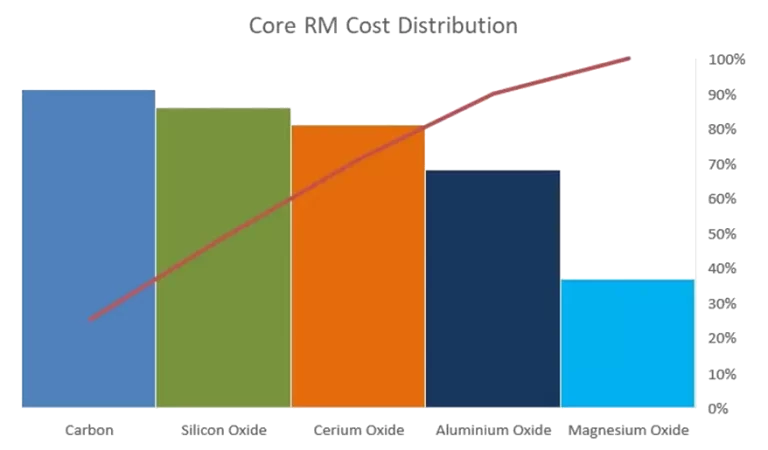

- Material Costs: This includes the cost of cerium oxide (ceria), magnesium oxide, silicon oxide and aluminium oxide (alumina) in powder form. Obtain quotes from suppliers or analyze market prices to determine the current material costs.Three main aspects are needed to find material cost of substrate:

- Raw material cost (discounts will be considered according to the volumes)

- Scrap cost

- Yield of part

For the raw material costing, we need the material loading on the substrate in core as well as in the coating. From SEM (Scanning Electron microscopy) with EDX (Energy Dispersive X-Ray) test, we will get the material loading.

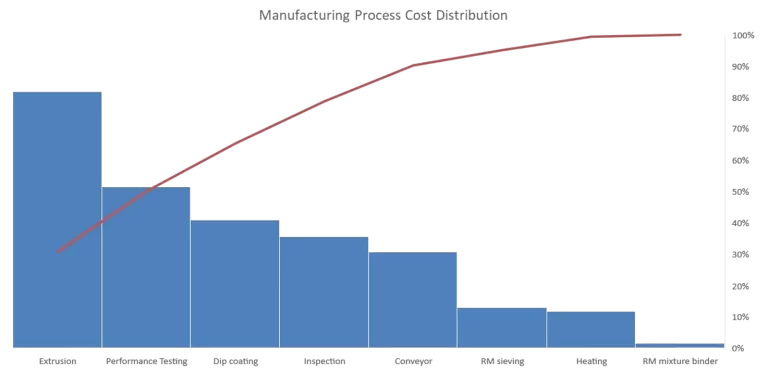

3. Manufacturing Process: Consider factors such as labour, machine, tool, and set-up costs associated with each manufacturing process. Evaluate the efficiency and productivity of the process to estimate the time and resources required.

- Labour hour rate: The labour hour rates depend upon the type of the labour used.

- Machine hour rates: The machine cost is calculated using type of machine used, machining time and efficiency of the machine.

- Tool cost: This includes the type of tool used and the life of tool.

- Set-up cost: This includes the cost of setting up the manufacturing process.

The cost of the manufacturing process depends upon the efficiency of the labour and machine. Below manufacturing processes are considered for costing:

- RM sieving

- RM binder

- Extrusion

- Conveyor

- Dip coating

- Heating Oven

- Inspection

- Performance testing

4. Overhead Costs: Factors in overhead costs such as facility maintenance, utilities, SG&A expenses, research and development, logistics, profits, and other indirect costs associated with the production of the ceramic substrate.

- Research and Development: If there were any research and development activities involved in developing the cerium-based ceramic substrate, include the associated costs. This can include expenses related to testing, prototyping, and process optimization.

- Packaging and Logistics: Estimate the cost of packaging the ceramic substrate for transportation and consider logistics costs associated with shipping the substrate to customers or manufacturers.

- SG&A expenses: These expenses are related to sell the substrate, general operation cost, and the administrative and management cost is considered.

- Profit Margin: Determine the desired profit margin for the ceramic substrate. This is the amount of profit the manufacturer aims to make on each unit sold.

Costing Analysis:

After studying the costing of cerium-based catalytic ceramic substrate, it is observed that the raw material cost, process cost, and the overhead cost accounts for a 38%, 33% and 29% of the total cost respectively.

In 38% of the raw material cost, the major contribution is from cerium oxide powder following with the aluminium oxide and silicon oxide powders. In 33% of the manufacturing cost, the extrusion process has huge impact on the cost. Finally in the overhead cost which is 29% of total cost, includes all indirect expenses incurred in manufacturing, such as rent, utilities, and administrative costs.