Consumer Electronics Should Costing

Powered by xcPEP, Delivered by ASI Engineering

ASI Engineering performs detailed should costing for consumer electronics—including smartphones, laptops, wearables, chargers, tablets, and related more—using xcPEP, our purpose built should-cost analysis software.. We work directly on complex product assemblies, mapping out every subcomponent, identifying materials and manufacturing routes, and building structured cost models that reflect real world sourcing and production logic.

This work enables critical business decisions such as setting target costs for new programs, benchmarking competing products, validating supplier quotes, or preparing for commercial negotiations. We cost both electronics and mechanicals—including PCB assemblies, internal frames, housings, thermal blocks, display modules, connectors, antennas, buttons, and structural plastics used in consumer electronics.

Whether it is evaluating a second source, comparing EMS options, or controlling costs across product cycles, ASI delivers clarity at the level of detail that high volume electronics programs demand.

Why traditional costing tools fall short in

Consumer Electronics Should Costing

Should costing in consumer electronics is uniquely complex due to the density of components, diverse manufacturing processes, and unstable sourcing conditions. A typical product combines PCBAs, moulded enclosures, thermal modules, optical stacks, and batteries, each with different cost drivers and supply risks. Cost decisions are often made early, before a stable design or supplier quote exists, and every design change can disrupt the cost structure.

Most costing software marketed as a should cost solution functions either as a BOM tracker or a price aggregator. A BOM tool monitors part numbers and purchase history, but cannot model tooling paths, production processes, or real overheads. A price aggregator reflects current procurement rates—not true manufacturing cost.

Despite this, each is often positioned as a should cost analysis tool—leading teams to believe they are controlling cost, when in reality, they are only tracking transactions.

ASI Engineering bridges this gap using xcPEP, our structured should-cost analysis software that models real production flows, sourcing logic, and part behavior to deliver accurate, part-level cost insights.

BOM tools help you find the lowest purchase price, but they do not tell you what a part should cost. They cannot model processes, tooling, or overheads. At their core they are filtered spreadsheets, not costing tools.

Component Price Volatility in Electronics Should Costing

Component prices in electronics are highly volatile. Passive components, ICs, displays, connectors, and batteries are all affected by global demand shifts, lifecycle transitions, geopolitical changes, and supplier constraints. Even a small design update or sourcing change can lead to sudden cost variation, making static price assumptions unreliable during program execution.

Intense Global Competition

Consumer electronics brands today face tough competition from all sides. Large manufacturers, especially from China, design and produce everything in-house, which helps them keep prices very low. At the same time, many companies use contract manufacturers who build for multiple brands at once, bringing down costs even further. This puts pressure on every product team to reduce cost while still meeting high design and performance standards.

Complex & Dense BOM

Consumer electronics products include hundreds of small parts packed into very limited space. This includes multiple printed circuit boards, flex cables, brackets, screws, fasteners, and thermal materials. Each item affects layout, assembly time, and overall cost. A small change in pad layout or connector orientation can impact tooling, yield, or rework effort. These interactions are hard to track, but they play a big role in total product cost. Traditional methods like Excel sheets or BOM tools are not equipped to capture and update these changes accurately or at the speed required.

High Import Dependency

Many key components in consumer electronics such as displays, connectors, camera modules, and high-density integrated circuits are sourced from outside the country. The final cost is affected not just by base price but also by freight, customs duty, currency exchange, and lead time. These factors change frequently and vary by region. Cost models that do not account for region specific sourcing and landed cost variation often miss the true impact of global supply dependencies.

Parts Shortage & Alternate Sourcing

Shortages of key components are common in consumer electronics. A single delayed IC or connector often leads teams to find alternates at short notice. But these substitutes are rarely simple swaps. Even if the electrical function is similar, changes in footprint, height, thermal behavior, or assembly method can affect the layout, tooling, test process, or regulatory approvals.

The cost impact is often indirect and not visible from the part price alone. Without a structured way to re-cost parts during alternate sourcing, teams risk introducing hidden costs that show up later in manufacturing or quality review.

No Should Cost Software Connecting Engineering and Sourcing

OEMs still rely on BOM spreadsheets, basic ERP exports, or procurement dashboards to manage product cost. These tools may track parts but do not explain the underlying cost structure. As a result, cost engineers, sourcing heads, and design teams often work in isolation without a common baseline for what the product should cost.

Electronics Should Costing in xcPEP

Covers detailed should costing of every part's raw material, manufacturing process and overheads.

Every Component's Should Costing

Electronics Should Costing Module

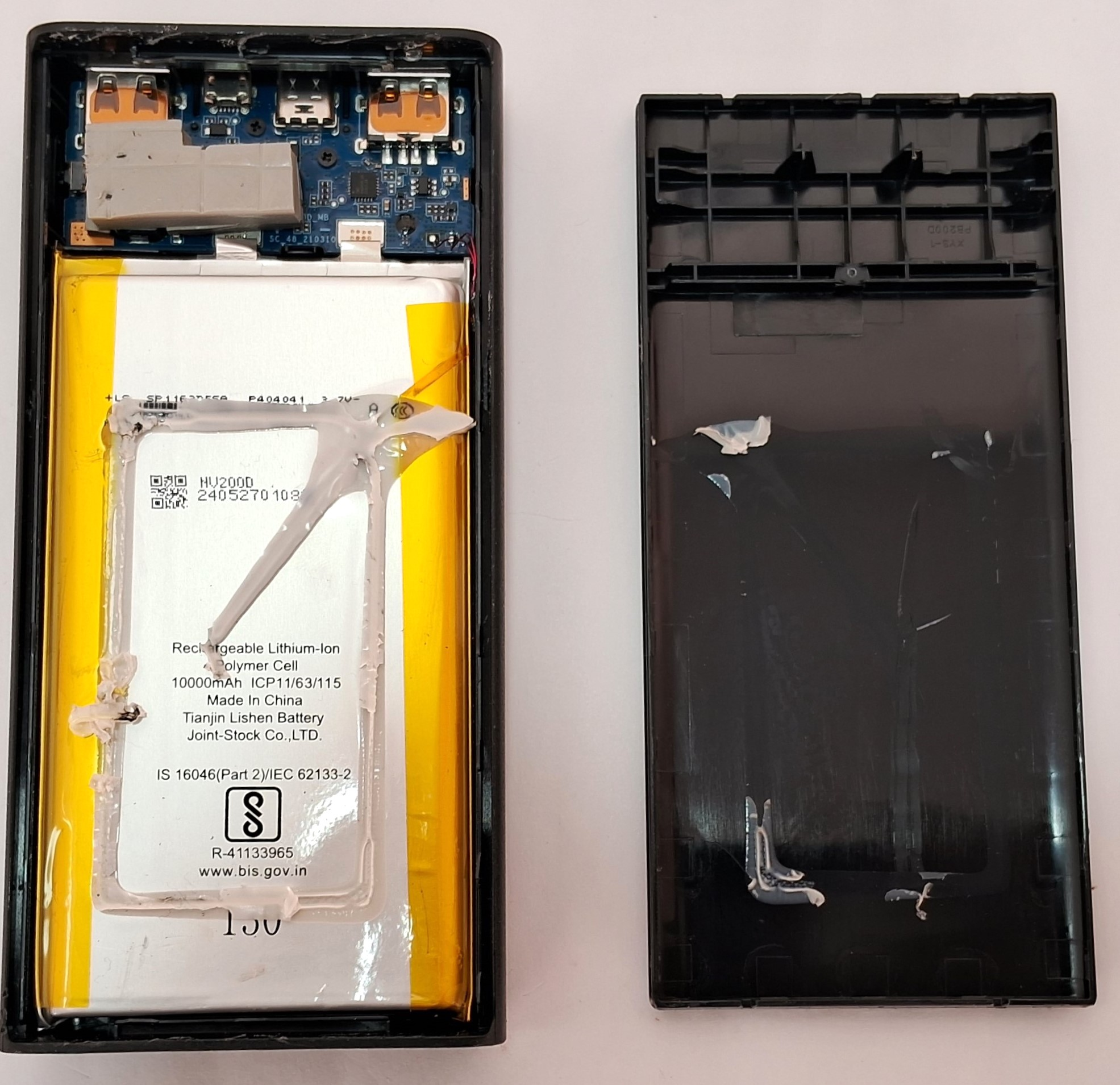

xcPEP is purpose-built for the cost modeling of consumer electronic products where high part density, complex assemblies, and rapidly shifting sourcing variables demand an engineering-led approach. The platform follows a structured should costing methodology, starting from teardown-based part data and simulating real-world production processes—such as machine selection, labour time, cycle duration, and tooling logic—across both electrical and mechanical domains.

Each component, from surface-mount devices on multilayer PCBs to injection-molded enclosures and battery packs, is costed using actual manufacturing logic and live cost data inputs. This includes supplier-specific sourcing rates, material prices, process overheads, and region-adjusted factors pulled via xcPROC.

As a should cost model software, xcPEP enables accurate, consistent cost estimation at both part and system levels—making it ideal for headphones, laptops, drones, and other consumer electronics products where scalability and speed are critical across design iterations.

In depth costing of PCB

ASI Engineering performs detailed should costing of PCB assemblies by modeling actual SMT logic. Each board is analyzed based on stack-up, component density, panel utilisation, soldering type, and placement speed. This includes parameters like via type, stencil wear, and yield loss based on pad layout and line configuration.

In depth costing of mechanical parts

ASI engineers build process-driven cost models for mechanical parts such as enclosures, heatsinks, internal frames, and cosmetic elements in consumer electronics products. These models are based on part geometry, material type, wall thickness, tooling configuration, and finish processes like vapor polishing, UV coating, or overmoulding.

xcPEP supports simultaneous costing of both mechanical and electrical parts in one platform, allowing a complete view of the product’s cost structure. This enables accurate comparison of part-level decisions like enclosure finish versus component layout, all in one environment.

Massive Library of Cost Models

ASI maintains a comprehensive library of cost models tailored to the manufacturing processes used in electronics — including SMT placement, soldering, PCB fabrication, injection moulding, CNC machining, ultrasonic welding, adhesive bonding, and thermal pad application. These models are used to simulate real manufacturing scenarios at part and assembly levels.

Each model is designed to handle the specific cost drivers of consumer electronics, from stencil wear in high-density PCBAs to cosmetic class handling in external plastics. All models are configurable within xcPEP to reflect plant-specific or supplier-specific variations, enabling consistent estimation across product types.

Precise Machine Database

xcPEP integrates with ASI’s internal machine-hour rate database, covering pick-and-place systems, reflow ovens, inspection equipment, presses, and finishing machines. Rates are region-specific and reflect real factory conditions rather than estimates.

ASI engineers use these machine datasets to ensure part cost models reflect true production economics, not flat-rate assumptions. Machine type, throughput, and cost per minute are directly applied in each relevant cost model.

Scenario Costing : Easily change PCB source to India from China

ASI uses xcPEP to simulate the impact of sourcing or process changes on part cost. Teams can instantly compare what a PCB would cost if sourced from China, India, or Vietnam by adjusting labour rates, overheads, freight, and machine rates.

Each scenario is saved and visualized inside xcPEP, making it easy to evaluate alternatives before making sourcing decisions. This is especially useful during EMS selection, alternate supplier validation, or new country entry planning.

Competitor Cost Benchmarking

The ASI engineering team builds complete should-cost models for competitor products using teardown data and process-level costing logic. Every part—electrical and mechanical—is modeled based on actual construction, including PCBs, displays, batteries, enclosures, connectors, and subassemblies.

All cost models are developed and stored inside xcPEP, allowing structured comparison with internal products at part, module, and system levels. This helps teams understand how competing products are built and where cost differences arise due to material choice, process flow, or sourcing decisions.

In Depth Data Analysis

All cost models built by ASI Engineering are stored in xcPEP, where they can be filtered, reviewed, and analyzed by process, part type, or sourcing region. Built-in dashboards help identify high-cost contributors, material outliers, or process inefficiencies.

This structured approach gives engineering, sourcing, and finance teams a common reference for all cost decisions. Reports and analytics are exportable, traceable, and always backed by engineering logic—not past prices.

Explore xcPEP — Our Platform for Electronics Should Costing

xcPROC – Cost Data Backbone for Electronics Costing

Automation & Intelligence in xcPEP

For unprecedented speed scale & Precision

With AI-driven PCB component identification and real engineering logic, xcPEP automates electronics costing at scale. From automated PCB component identification to dynamic cost model generation, the system is designed to keep up with fast-moving product cycles and volatile supply chains. This makes xcPEP the most advanced electronics costing platform for OEMs, engineering teams, and sourcing professionals.

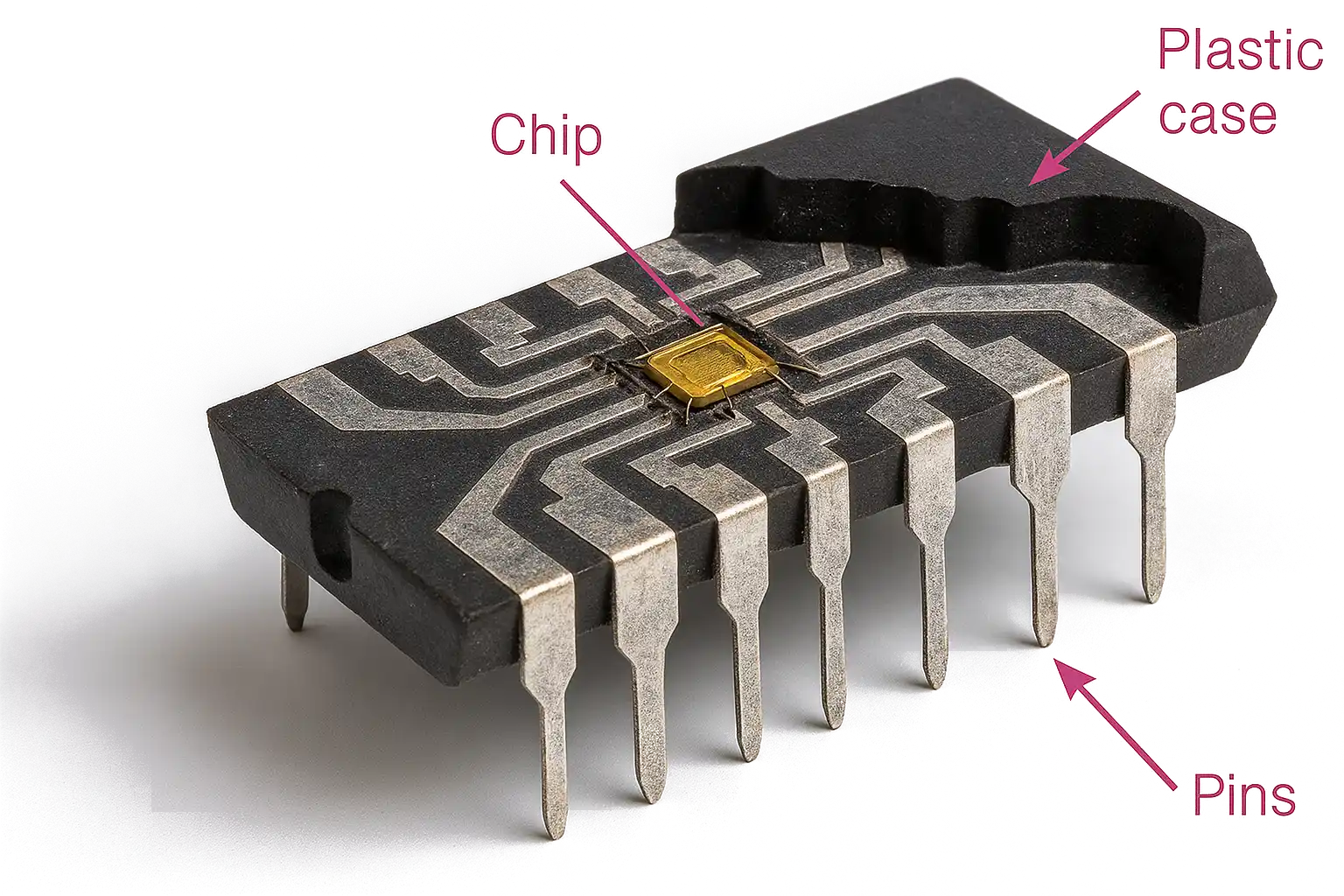

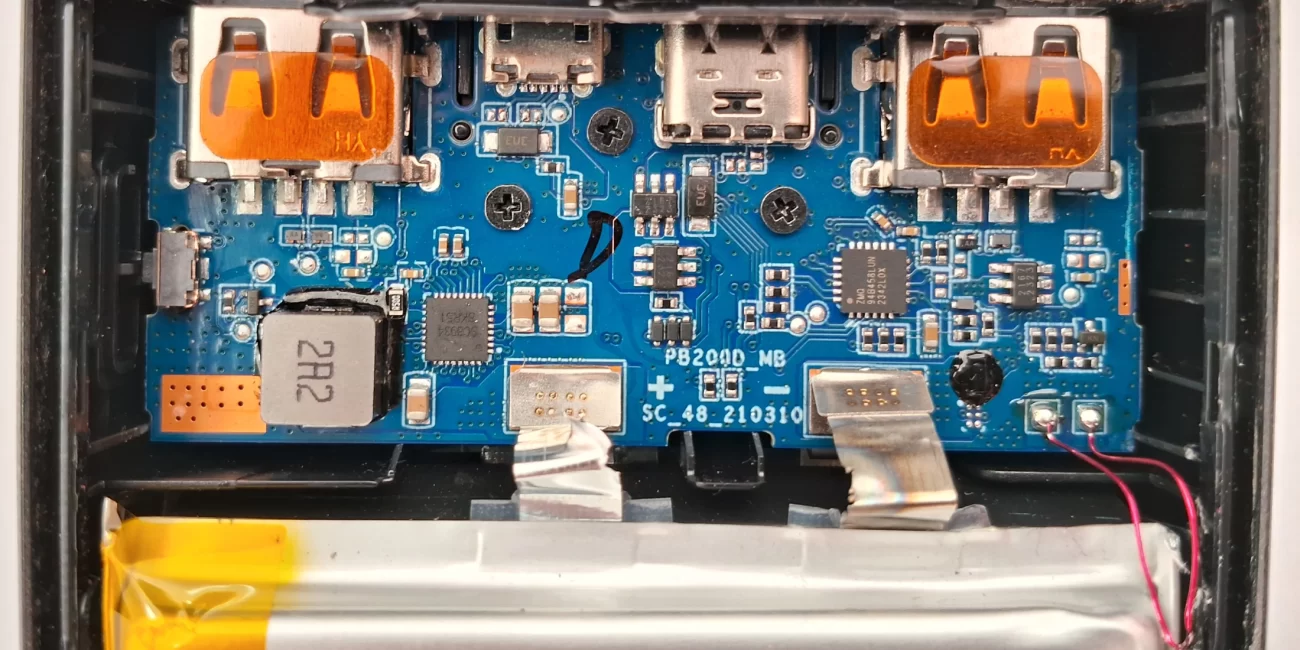

xcPEP starts by analyzing teardown images of the PCB using high-resolution microscopes. AI algorithms automatically detect, classify, and extract every component mounted on the board — including ICs, resistors, capacitors, connectors, and other SMDs.

Once a component is identified, the system queries xcPROC — our internal marketplace and electronics database — along with other public sources. It fetches complete details such as part name, specification, packaging type, pricing, availability, RoHS compliance, and alternate options. This data is directly fed into xcPEP’s dynamic cost models, enabling fast, accurate, and engineering-grade costing with minimal manual input.

To learn how xcPEP works with our Bounding Box and Projected Area Capture systems for even richer input data, visit the xcPEP page.

How are we different?

At our core, we build cost engineering technology. Our primary focus is on xcPEP and xcPROC, while our engineering services are designed to support and accelerate customer adoption of our ecosystem.

BOM based tools

Management Consultants

xcPEP + ASI Engineering

Technology for electrical parts costing

Technology for electronics parts costing

Technology for mechnical parts costing

Child part BOM cost management

Manufacturing process detailed costing

Overhead detailed assumptions

Automated data mapping for benchmarking

Build Your Own Internal Electronics Cost-Lab

Use Cases

Internal Cost Lab Setup

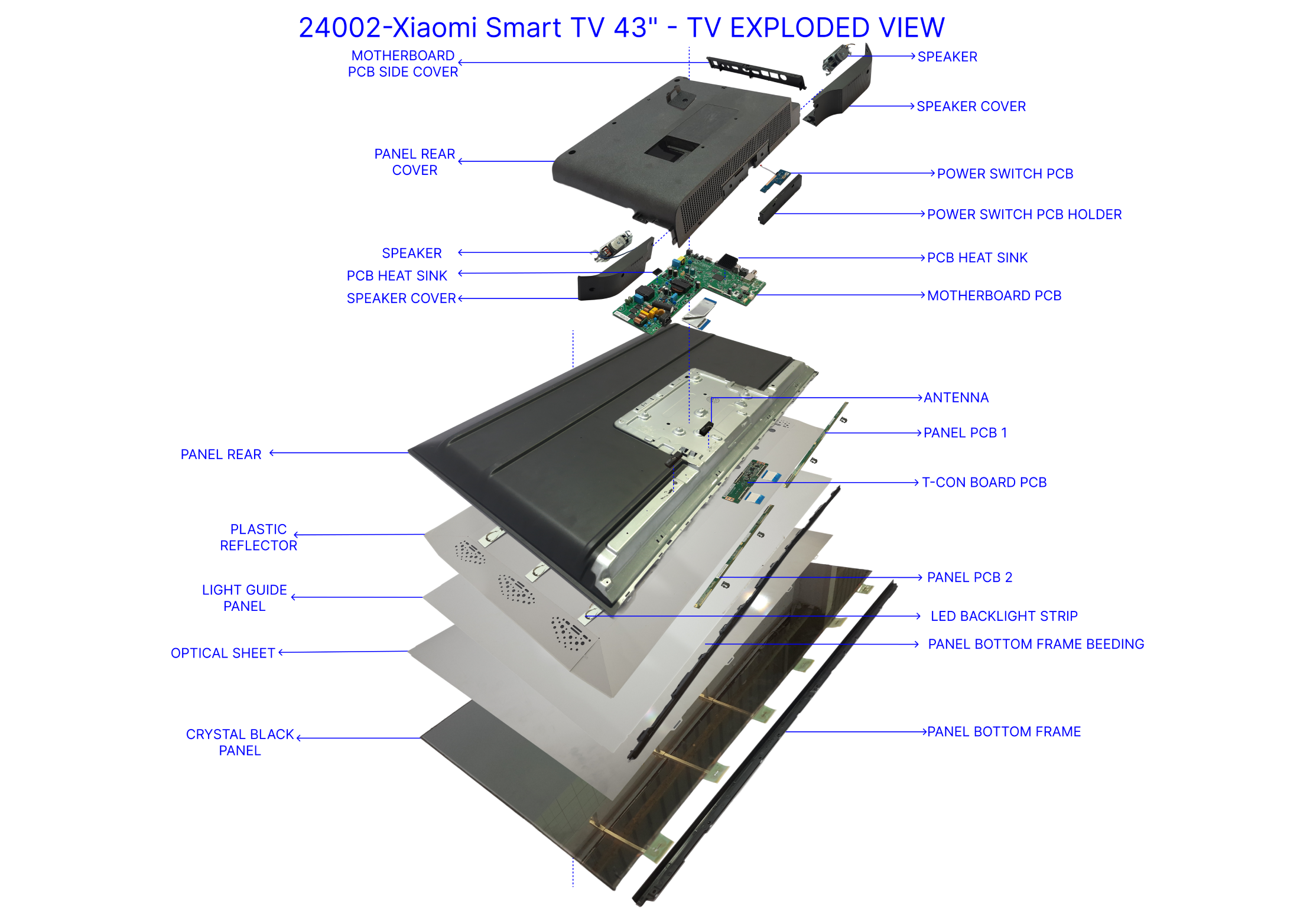

xcPEP was deployed to set up an internal cost lab for global consumer electronics brand focused on televisions, display units, and entertainment accessories.

The ASI Engineering team managed the entire setup—migrating legacy costing data, configuring part templates and manufacturing process logic specific to the client’s product lines, and integrating region-specific input rates using the xcPROC database. This included routing assumptions for components such as display frames, thermal shielding, backlight enclosures, speaker housings, and IR sensor modules. ASI worked alongside the client’s teams during the initial phase, executing the first few costing projects to demonstrate how to structure detailed models and simulate sourcing alternatives.

The engagement followed a Build–Operate–Transfer (BOT) model. Once the internal cost lab was stabilized, full control was handed over to the client. Today, their team runs the lab independently, with ASI providing regular database updates and ongoing support as needed.

Should-Costing for New Part Development

A leading mobile and wearables brand engaged ASI Engineering to define cost targets for an upcoming smartwatch platform during its early concept phase. The ASI Engineering team built structured cost models directly from CAD data and preliminary BOMs, well before EMS sourcing or supplier quotations had begun. These models covered key assemblies such as the mechanical housing, display stack, PCBA layout, and connector modules.

Using xcPEP, all inputs were configured with validated data from xcPROC, including material grades, CNC routing logic, FPC processing methods, SMT cycle times, and labor rates across relevant sourcing regions. As the design evolved, the models were continuously updated to reflect changes in geometry, component splits, finish treatments, and internal architecture. For a broader industry perspective on early-phase electronics cost estimation, see this IEEE research article.

This approach enabled the client's cross-functional teams to align early on realistic cost targets, make informed design decisions, and enter sourcing discussions with a clear internal reference—avoiding last-minute surprises during supplier negotiations.

Fact Packs for Supplier Negotiations

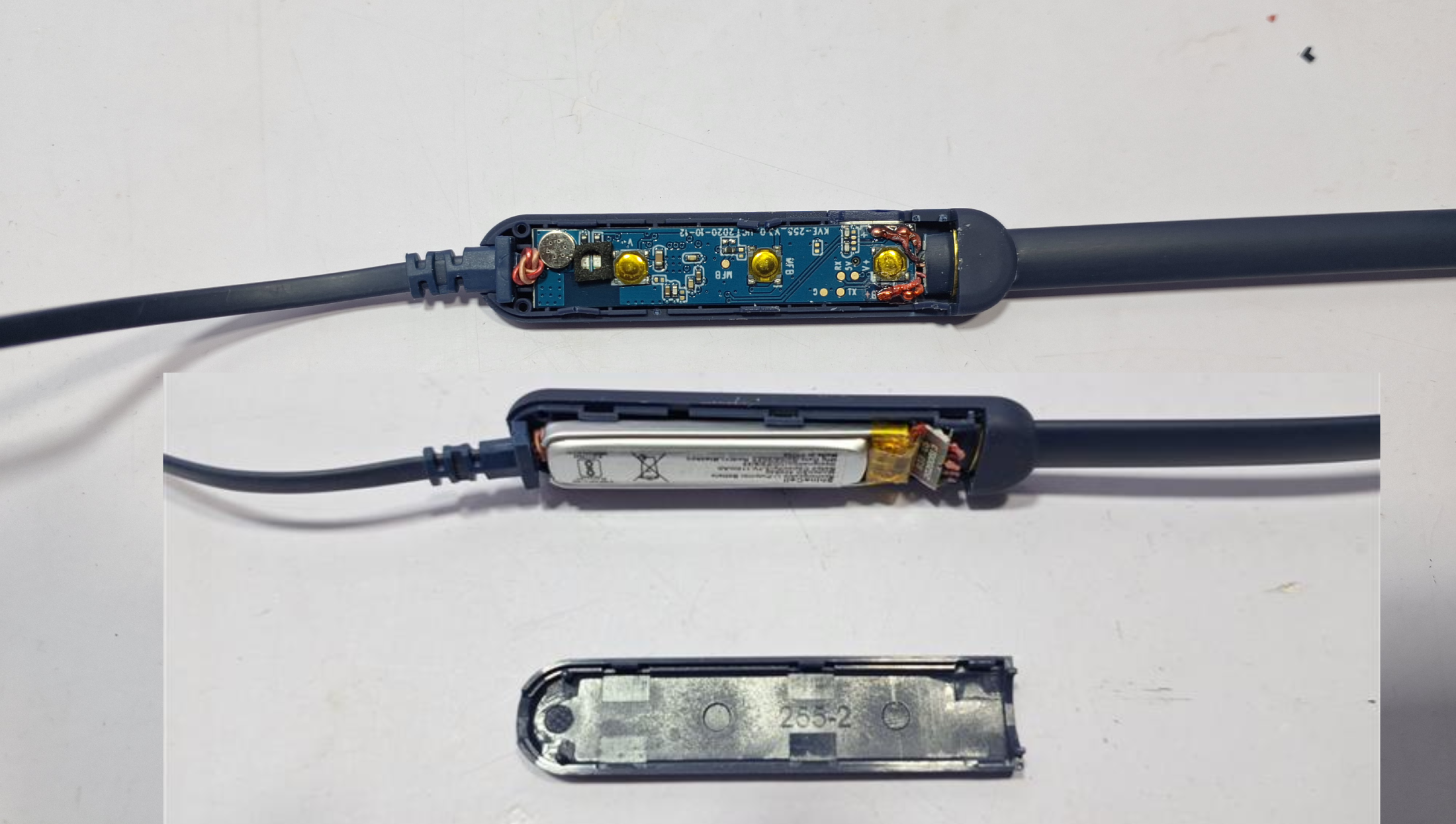

A consumer electronics brand engaged ASI Engineering to support negotiations for a new line of Bluetooth earphones. ASI Engineering team-built part-level cost models for key components including PCBA modules, over molded earbud housings, charging cases, battery packs, and connectors. Each model reflected actual manufacturing steps—such as SMT line setup, injection molding cycle time, and welding operations—configured using real-world input rates from xcPROC inside xcPEP.

The outputs were compiled into fact packs showing expected cost breakdowns, key assumptions, and cost drivers. These packs gave the sourcing team a structured basis to question quotes, challenge inflated conversion costs, and negotiate with clarity.

Product Studies

Cost engineering studies executed by ASI Engineering Team , focused on consumer electronics.

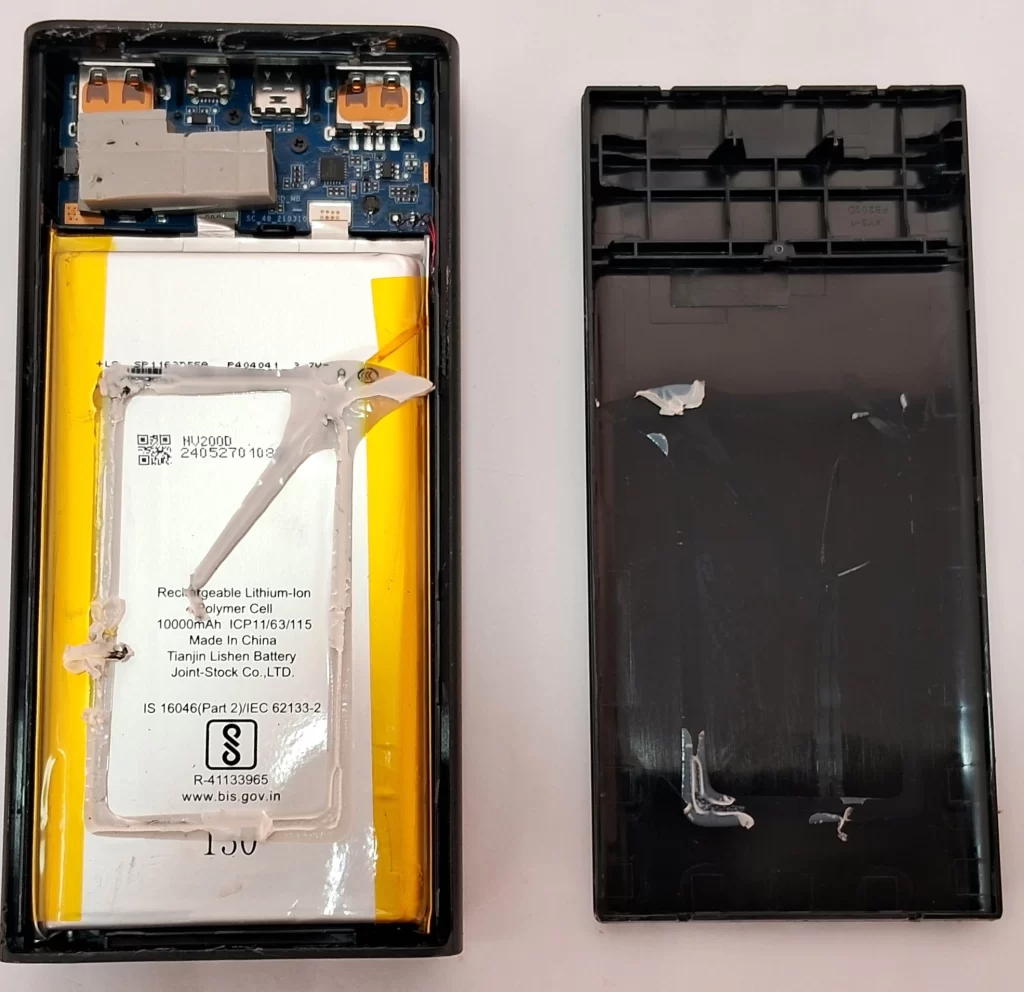

This section features teardown-based costing projects executed entirely by the ASI Engineering team across high-volume consumer electronics—smartphones, laptops, wearables, chargers, audio devices, and more.

Every image, model, and cost breakdown shown here is based on ASI’s own internal work. These studies demonstrate how structured cost models can be built using real manufacturing logic, grounded process flows, and validated input assumptions.

From PCBA assemblies and display modules to injection-molded housings and battery enclosures, each case illustrates how detailed part-level costing helps explain complexity, trace cost drivers, and benchmark alternatives. All models are created using xcPEP, with rate data and routing configurations drawn from xcPROC.