Hydraulic Motor Teardown and Should Cost Analysis

Disclaimer

This study was conducted entirely in-house by ASI Engineering to demonstrate the capabilities of the xcPEP® platform. The product was independently procured by ASI. No proprietary or confidential information from any other party has been used. Results are not updated after publishing.

Software platforms used for this study

This study is powered by ASI’s proprietary should-costing ecosystem - xcPEP and xcPROC - engineered to deliver real-world accurate, traceable should-costing across mechanical, electrical, and electronics components..

xcPEP delivers real-world accurate, transparent & defensible should cost analysis of mechanical, electrical & electronics components from drawings or physical parts.

Explore xcPEP →

xcPROC is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific.

Explore xcPROC →Introduction: The Strategic Imperative of Hydraulic Motor Teardown and Should Costing for Industry Leaders

Hydraulic motors stand as foundational components across a myriad of heavy-duty applications, particularly within the demanding realm of off-highway vehicles such as excavators, loaders, harvesters, and mining machinery. These vital actuators are engineered to convert hydraulic pressure into mechanical energy, efficiently delivering the torque and rotation indispensable for driving complex machinery. In an increasingly competitive global market, understanding the intricacies of these components, both mechanically and economically, is not merely advantageous but strategically imperative.

Understanding Hydraulic Motors: Fundamentals, Types, and Key Applications in Heavy-Duty Machinery

To fully appreciate the depth of a hydraulic motor teardown and should cost analysis, a foundational understanding of these mechanical actuators is essential. This section delineates their core function, explores common types prevalent in off-highway applications, and highlights their critical performance characteristics and widespread uses.

What is a Hydraulic Motor?

At its core, a hydraulic motor functions as a mechanical actuator designed to convert hydraulic energy—derived from fluid pressure and flow—into rotary mechanical energy, manifested as torque and rotation. This conversion is fundamental to the operation of countless industrial and mobile machines, enabling the precise and powerful movement of heavy loads.

Common Types of Hydraulic Motors in Off-Highway Vehicles

The landscape of hydraulic motors used in off-highway vehicles is diverse, each type offering distinct advantages for specific applications. Common configurations include Gear Motors (both External and Internal), Piston Motors (Axial and Radial), Vane Motors, and Gerotor/Geroler Motors. This variety underscores the specialized demands of heavy machinery, where different operational requirements necessitate tailored motor designs.

Applications and Performance Characteristics

Hydraulic motors are indispensable in a wide array of heavy-duty machinery, including excavators, loaders, skid steers, harvesters, and mining equipment. Their widespread adoption is attributable to a suite of key features that make them exceptionally suited for demanding environments. These features include variable displacement, which allows for flexible operation; a high-pressure range, typically up to 450 bar continuous and 500 bar peak; and a bent-axis design, which contributes to higher efficiency and power density. They also boast a wide displacement range, from 28 to 1000 cm³, offer modular options for easy integration, and possess high-speed capability, often with optional flushing and boost pressure features.

Inside the Machine: A Detailed Hydraulic Motor Teardown

This section delves into the specifics of the hydraulic motor teardown, focusing on the particular product chosen for the study and a detailed examination of its core internal components, including their functions and material compositions.

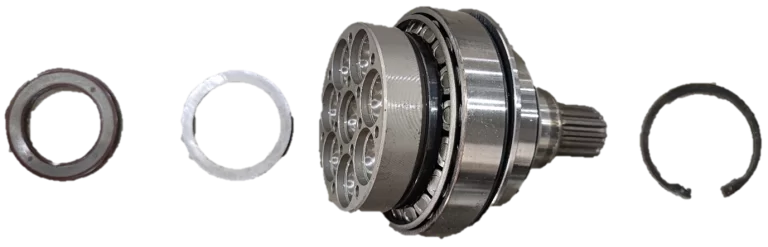

The Axial Piston Variable Motor: Product Used for Study

For this comprehensive study, an Axial Piston Variable Motor was selected, a type commonly integrated into heavy machinery such as excavators, loaders, skid steers, harvesters, and mining equipment. The Bill of Material (BOM) analysis, a critical part of this teardown, was specifically conducted on a Rexroth hydraulic motor. This choice of a widely recognized industrial component lends significant real-world relevance to the study, allowing for direct comparisons and practical application of the findings.

Core Internal Components: Function and Material Insights

A thorough examination of the hydraulic motor's internal architecture reveals several key components, each meticulously designed with specific functions and material selections to ensure optimal performance and longevity:

Hydraulic Motor Housing - FG Cast Iron

This primary enclosure protects all internal components from external contaminants and mechanical damage. Beyond protection, it provides essential structural support and serves as a reservoir for lubricating and return fluid. The material chosen for the housing is FG (Flake Graphite) Cast Iron.

Cylinder Block of Hydraulic Motor - Heat Treated Steel

As a central rotating element, the cylinder block houses multiple axial pistons arranged in a circular configuration. It acts as the primary torque-transmitting member, directly interacting with the drive shaft to convert hydraulic energy into mechanical rotation. This critical component is manufactured from Heat-Treated Steel.

Axial Pistons - Hardened Steel

These precision-machined components reciprocate axially within the cylinder block under hydraulic pressure. They are instrumental in converting hydraulic energy into mechanical force, which in turn contributes to torque generation as they act upon the swash plate or rotating group. The pistons are made from Hardened Steel.

Valve Control Housing of Hydraulic Motor - FG Cast Iron

A stationary component, the valve plate contains a series of ports and timing grooves crucial for regulating the inflow and outflow of hydraulic fluid to and from the piston chambers. Its design ensures proper phasing of fluid distribution, which is vital for efficient operation. Like the main housing, this component is made from FG (Flake Graphite) Cast Iron.

Drive Shaft of Hydraulic Motor - Alloy Steel

Mechanically coupled to the cylinder block, the drive shaft is the conduit for transmitting the mechanical load generated by the motor. Its material, Alloy Steel, is selected for its strength and durability.

Bearings used in Hydraulic Motor

Essential for supporting rotating elements such such as the drive shaft and cylinder block, bearings minimize frictional losses and wear. They are indispensable for maintaining alignment and ensuring reliable, long-term performance under high load and speed conditions. The types identified in this motor include Needle bearings and Ball bearings.

Material Selection Strategy in Hydraulic Motor Design

The selection of materials for each component reflects a deliberate engineering strategy, balancing performance requirements with manufacturing considerations.

For instance, FG Cast Iron is chosen for the housing and valve control housing due to its favorable damping properties, machinability, and relatively lower cost for large, complex castings. This makes it suitable for static structural elements that also contain fluid, where formability and cost-effectiveness are prioritized over extreme lightness.

In contrast, Heat-Treated Steel for the cylinder block and Hardened Steel for the pistons are selected for their superior strength, wear resistance, and fatigue life, which are critical for components subjected to high pressures, friction, and continuous motion. The "heat-treated" and "hardened" aspects signify specific metallurgical processes employed to enhance these properties, directly contributing to the motor's durability and longevity under extreme operating conditions.

Similarly, Alloy Steel for the drive shaft is chosen for its high tensile strength and torsional rigidity, vital for transmitting significant mechanical loads without deformation or failure.

This pattern of material selection highlights a calculated engineering trade-off: utilizing cost-effective, easily processed materials for bulk, static components, while reserving higher-performance, more expensive, and specially treated steels for critical, dynamic, load-bearing parts. This understanding is foundational for any subsequent design-to-cost initiatives or evaluations of material alternatives.

How Hydraulic Motors Work: The Bent-Axis Design Principle

The hydraulic motor studied employs a bent-axis design, a configuration that sets the cylinder block and the drive shaft at a specific angle to each other. Within the cylinder block, pistons are arranged in a circular pattern. As pressurized hydraulic fluid enters the motor, it exerts force on these pistons, causing the cylinder block to rotate. The inherent angle between the shaft and the cylinder block translates this rotational motion into the rotation of the drive shaft, thereby producing torque. A key feature of this design is its variable displacement capability, meaning the angle of the swashplate can be adjusted. This adjustability allows for precise control over the motor's output torque and speed, providing flexibility and efficiency across various operational demands.

Key Features of Hydraulic Motor

- Variable displacement for flexible operation.

- High pressure range (up to 450 bar continuous, 500 bar peak).

- Bent-axis design for higher efficiency and power density.

- Wide displacement range (28 to 1000 cm³).

- Modular options for easy integration.

- High-speed capability with optional flushing and boost pressure.

Applications of Hydraulic Motor

- High Torque at Low Speed

- Compact Size for Integration

- Variable Displacement for Efficiency

- Robust Design for Heavy-Duty Use

- Reliable Performance in Harsh Environments

Deconstructing Value: Bill of Material (BOM) Analysis of a Hydraulic Motor

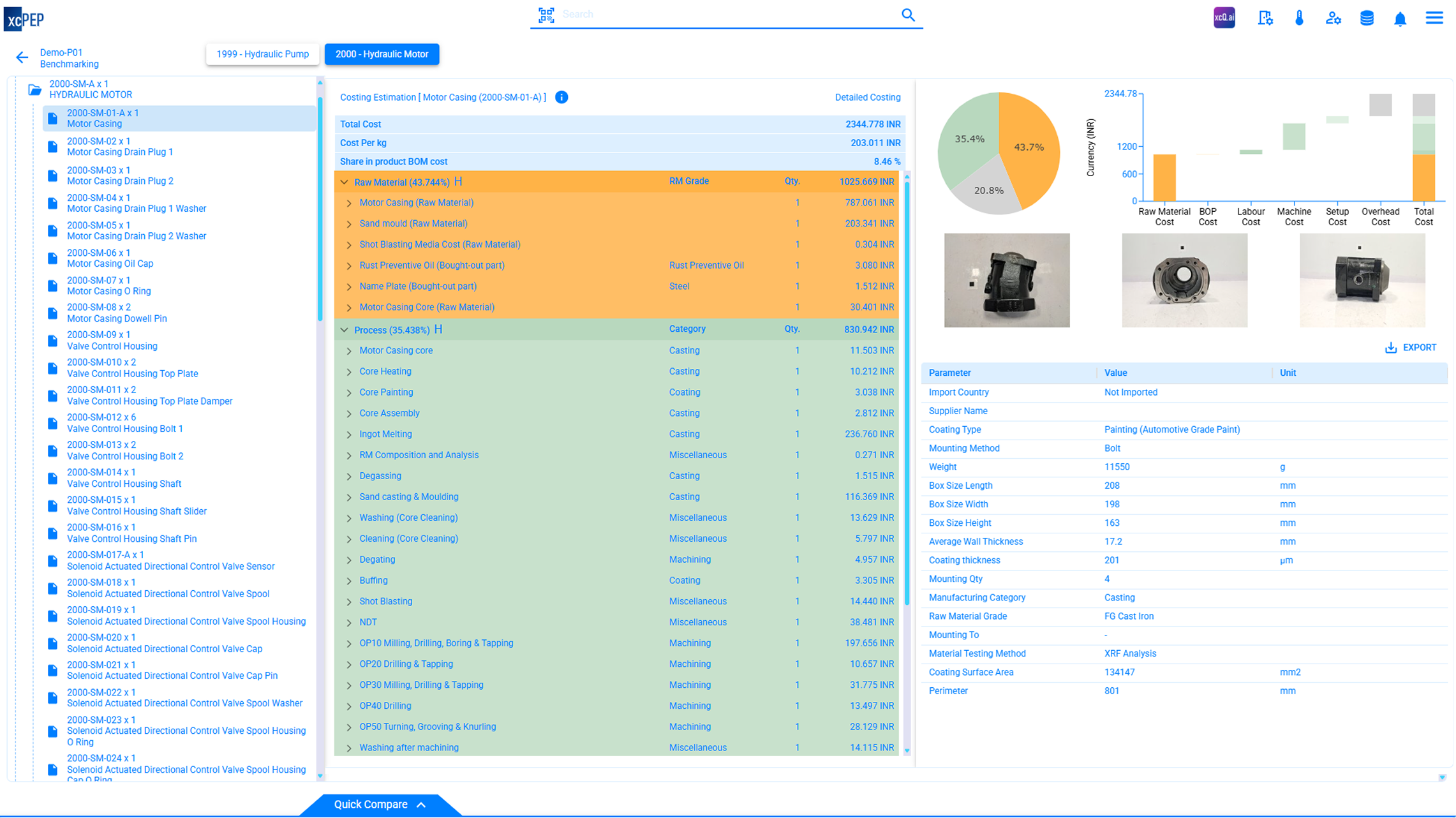

A detailed product teardown of the Rexroth hydraulic motor was undertaken to systematically study its internal components and overall system architecture. This rigorous analysis involved meticulously examining data related to various part attributes, providing a deep understanding of the motor's design, construction, and operational functionality. Following the physical teardown, a comprehensive Multi-level Bill of Material (BOM) structure was developed, offering granular insights into each individual component and its role within the assembly.

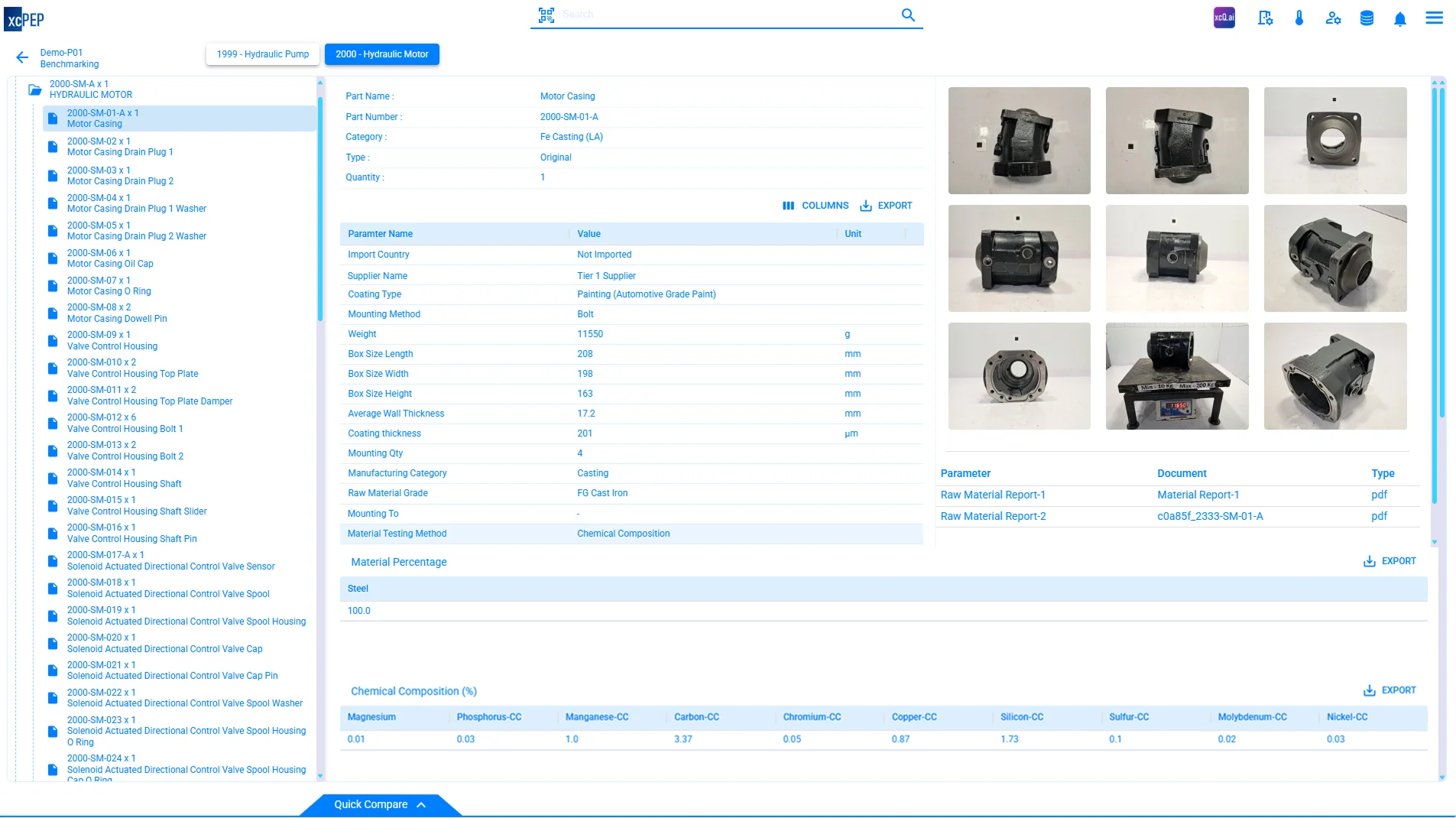

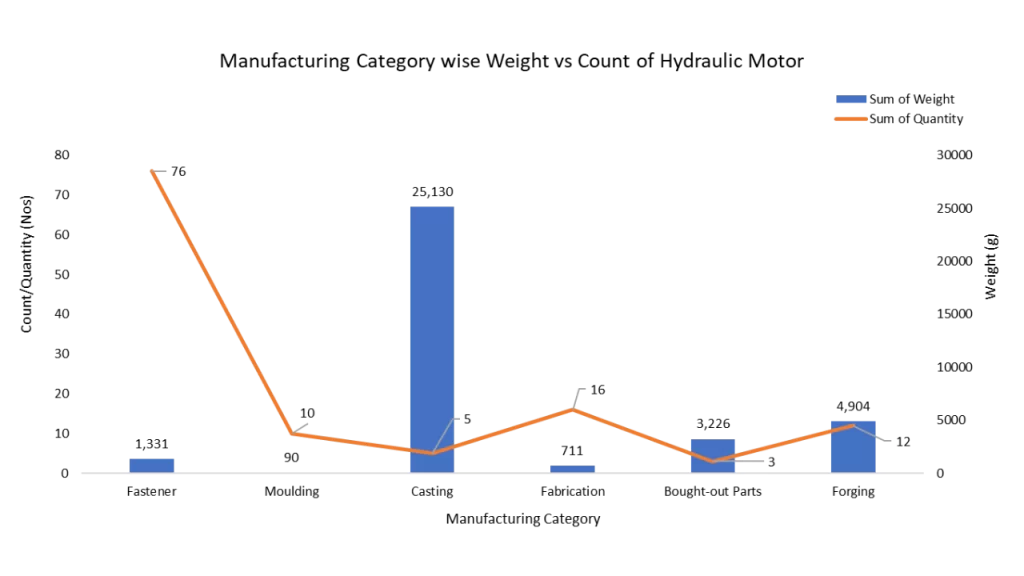

Manufacturing Category-wise Weight vs. Count Comparison of Hydraulic Motor

To gain a clearer perspective on design priorities and identify weight-intensive contributors, an analysis was performed evaluating both the quantity and total weight of parts categorized by their manufacturing type. The findings, presented in Table 1, reveal distinct patterns in component distribution and mass concentration.

Weight vs. Quantity Insights

- The Casting category dominates the total weight at 25,130 g, despite comprising only 5 components, suggesting these are the primary structural elements of the hydraulic motor.

- Fasteners are the most numerous, with 76 items, but their combined weight is only 1,331 g, indicating that they are small but essential for assembly integrity.

Category-specific Observations

- Forging components contribute 4,904 g across 12 items, likely representing key load-bearing or high-strength parts within the motor.

- Bought-out Parts, though limited to just 3 items, weigh in at 3,226 g, suggesting the inclusion of dense or precision-engineered elements sourced externally.

- Fabrication accounts for 711 g from 16 components, probably supporting structures or brackets in the motor.

- Mouldings make up the smallest weight segment (90 g) across 10 items, possibly representing non-load bearing or insulation parts.

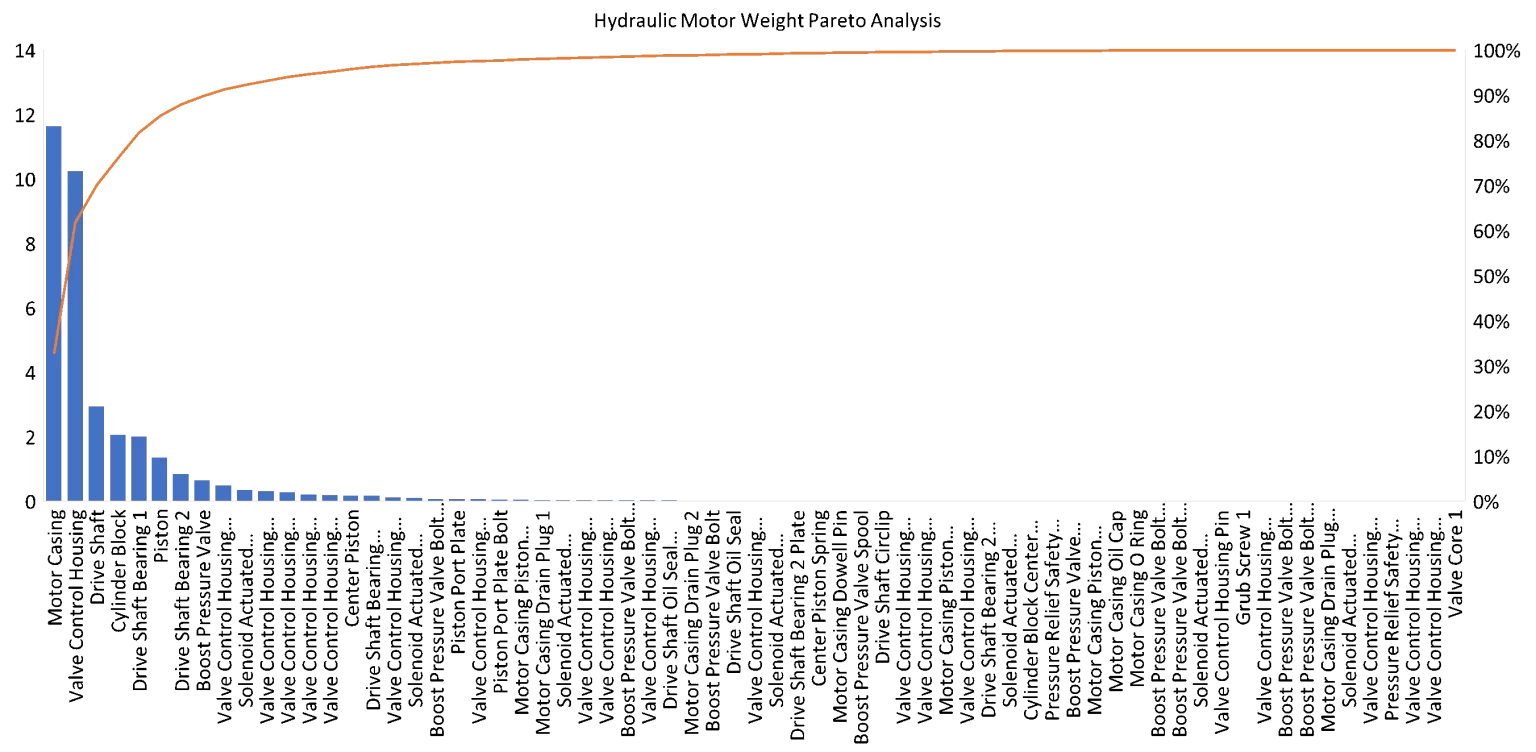

Hydraulic Motor Weight Pareto Analysis

As part of a detailed teardown, Bill of Materials (BOM), and should costing study of a hydraulic motor, we performed a comprehensive bill of material exercise to identify weight contributors across the assembly. The resulting Weight Pareto Analysis reveals that a small number of components contribute to a majority of the total weight, helping prioritize cost optimization efforts and alternative material evaluations. This chart forms a critical input for design-to-cost initiatives in off highway and industrial hydraulic applications.

Key Insights from the Weight Pareto Analysis:

- The top 3 components—Motor Casing, Valve Control Housing, and Drive Shaft—contribute over

60% of the total assembly weight. - Drive Shaft and Cylinder Block, though smaller in number, are significant contributors and should be evaluated for alternate materials or hollow designs without compromising torque transmission.

- Beyond the top 20 parts, over 100 components each contribute less than 0.5% to total weight—these include fasteners, dowel pins, springs, and seals, which have minimal impact on total mass but can influence part count and assembly time.

The True Cost Revealed: Hydraulic Motor Should Cost Analysis

We have conducted a last-level teardown of the hydraulic motor, and the following are key outcomes from the study. In the costing analysis, data related to various part attributes were mapped and analysed to gain a detailed understanding of the entire hydraulic motor assembly.

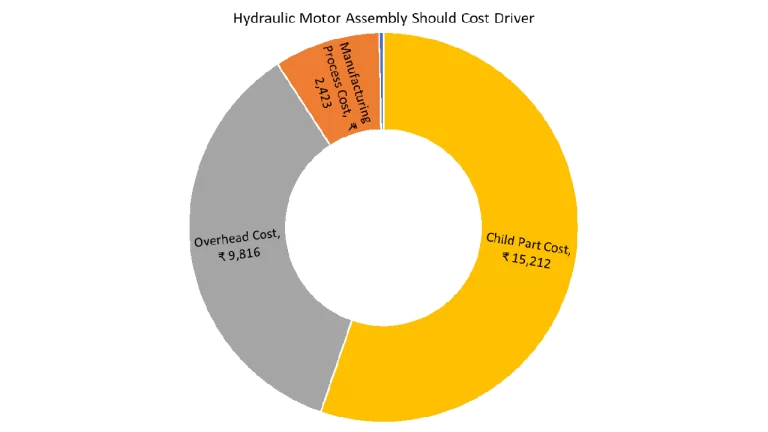

Should Cost Drivers of Hydraulic Motor

A Comprehensive teardown, Bill of Material and Should Costing analysis of the hydraulic motor was carried out, resulting in a calculated manufacturing cost of INR 27,550.42. The following considerations were factored into the study:

- The hydraulic motor is manufactured in Bengaluru, India

- The production volume considered for the analysis was 2,500 units annually

- The latest material rates and values required for MHR (Machine Hour Rate) calculations were based on Q4 FY24–25 data.

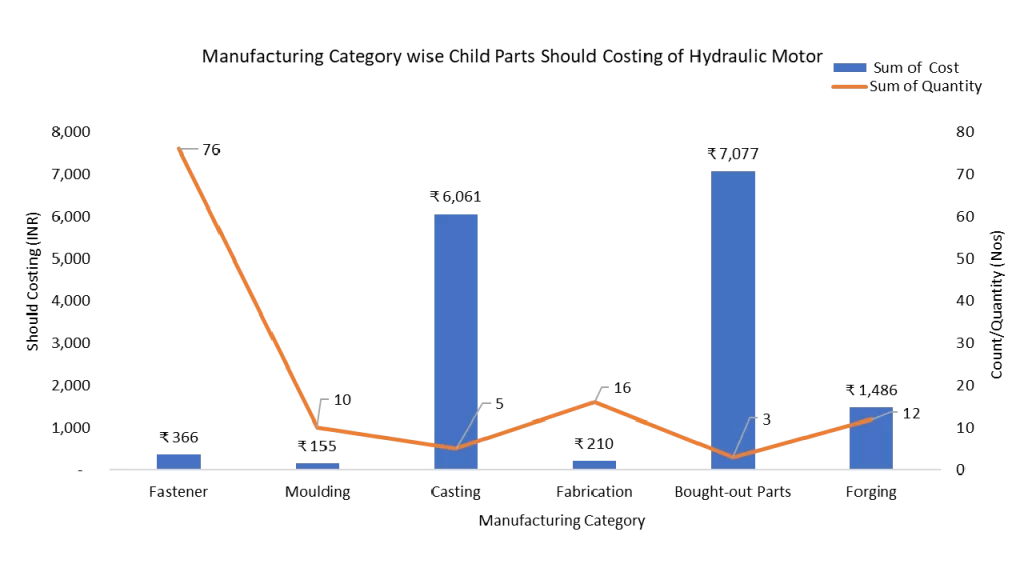

Manufacturing Category-wise Should Costing of Hydraulic Motor

In the teardown analysis of hydraulic motor components, it’s essential to examine not only the quantity of parts but also their corresponding should cost. This breakdown helps identify cost-intensive elements and guides value engineering efforts across manufacturing categories.

Cost vs. Quantity Insights

The Bought-out Parts category contributes the highest total cost at ₹7,077, despite comprising only 3 components, indicating high-value, possibly precision or proprietary items sourced externally

Category-specific Observations

- Casting components account for a significant cost of ₹6,061 from just 5 items, suggesting they are major structural or machined parts within the hydraulic motor.

- Fasteners are the most numerous, with 76 pieces, but their total cost is only ₹366, highlighting their low unit price yet essential role in assembly.

- Forging components cost ₹1,486 across 12 items, indicating parts that are strength-critical or shaped for specific load-bearing functions.

- Fabrication involves 16 parts at a total cost of ₹210, likely comprising minor brackets, supports, or non-complex welded structures.

- Moulding parts have the lowest cost contribution at ₹155 for 10 items, potentially representing insulation covers or non-structural elements.

Strategic Insights & Optimization Opportunities from Teardown and Should Costing

The detailed teardown and should cost analysis of the hydraulic motor yield a wealth of actionable intelligence, offering clear pathways for design optimization, manufacturing efficiency improvements, and strategic procurement.

Design-to-Cost Initiatives and Material Alternatives

The Weight Pareto Analysis specifically identified the Motor Casing, Valve Control Housing, and Drive Shaft as collectively contributing over 60% of the total assembly weight. This concentration of mass in a few key components provides a clear directive for design-to-cost initiatives. For instance, the Drive Shaft and Cylinder Block, being significant weight contributors, should be thoroughly evaluated for alternate materials or hollow designs. Exploring lighter alloys, advanced composites (where appropriate for performance and cost), or innovative structural designs that reduce material usage without compromising integrity can lead to substantial weight reductions. Such design modifications not only lower material costs but also positively impact shipping expenses and potentially enhance the operational efficiency of the end product by reducing overall vehicle weight.

Procurement Strategy and Value Engineering Potential

The should cost analysis unequivocally demonstrated that "Bought-out Parts" represent the highest total cost contributor, accounting for ₹7,077 from just 3 components. This finding is critical for shaping procurement strategies. Given their high value, these components are prime targets for intensive supplier negotiation, exploring second-sourcing options to foster competition, or even considering in-house manufacturing if the volume and strategic importance warrant the investment. Value engineering efforts should be specifically directed at these high-cost bought-out components, seeking functional equivalence at a lower cost through design simplification, material substitution, or alternative sourcing. The overall calculated manufacturing cost of INR 27,550.42, based on a production volume of 2,500 units annually in Bengaluru, India, provides a precise benchmark for these procurement and value engineering discussions.

Design for Manufacturability (DFM): Reducing complexity, minimizing the number of assembly steps (e.g., fewer fasteners), and simplifying specialized processes.

Design for Assembly (DFA): Streamlining how parts fit together to reduce manual labor time and potential for errors.

Supply Chain Optimization: Negotiating better prices for bought-out parts, identifying and developing alternative suppliers, or even strategically insourcing production if it demonstrably reduces the overall MHR and material cost. This integrated approach moves beyond simple material substitution to a broader strategic framework that encompasses the entire manufacturing and supply chain process, driving more profound and sustainable cost reductions.

Furthermore, the detailed "should cost" figure, coupled with specific parameters like manufacturing location (Bengaluru, India), annual production volume (2,500 units), and data currency (Q4 FY24–25), serves as a powerful external benchmark. Companies can leverage this "should cost" as a target price during negotiations with suppliers, providing a data-driven basis for discussions. It also acts as a baseline against which competitors' estimated costs can be compared. If a supplier's quoted price significantly exceeds the calculated "should cost," it provides strong leverage for negotiation. Similarly, if a competitor's product is perceived to be more cost-effective, this analysis helps pinpoint the underlying reasons, such as different material choices, manufacturing locations, or economies of scale achieved through higher production volumes. This transforms an internal cost analysis into a potent tool for external competitive intelligence and strategic market positioning.

Conclusion: Leveraging Teardown and Should Cost Analysis for Competitive Advantage and Innovation

The detailed hydraulic motor teardown and subsequent should cost analysis provide invaluable insights into the intricate relationship between design, manufacturing processes, and overall product cost. By systematically dissecting the motor, analyzing its Bill of Material, and quantifying the cost contributions of each component and manufacturing category, this study has illuminated critical areas for optimization. The analysis clearly identified the major weight contributors (e.g., Motor Casing, Valve Control Housing, Drive Shaft) and, crucially, the primary cost drivers (e.g., Bought-out Parts), demonstrating that weight and cost do not always correlate directly.

The findings underscore that while heavy structural components dictate overall mass, high-value, often proprietary, bought-out parts significantly influence the final manufacturing cost. This distinction necessitates a multi-faceted approach to cost reduction, involving not only design-to-cost initiatives like material substitution and structural optimization but also aggressive procurement strategies focused on high-cost external components. Furthermore, the analysis highlighted the indirect costs associated with assembly complexity, particularly due to the high count of fasteners, pointing towards opportunities for design for assembly improvements.

It is important to recognize that a single teardown and should cost analysis, such as this study, represents a snapshot in time. Market conditions, including material prices and labor rates, along with technological advancements and competitive pressures, are in constant flux. Therefore, product optimization through teardown and should costing is not a one-off event but rather an ongoing, iterative process. Companies that regularly perform such analyses are better equipped to adapt to market changes, identify emerging opportunities for cost savings, and drive continuous innovation in their product lines. The systematic approach facilitated by platforms like xcPEP® is instrumental in transforming raw data into actionable business intelligence, making complex engineering and cost analyses repeatable and scalable across an entire product portfolio. By continuously leveraging these analytical tools, organizations can make data-driven decisions that lead to significant cost savings, improved product performance, and a sustained competitive advantage in the dynamic heavy-duty machinery market.