Off-Highway Vehicles Benchmarking & Cost Reduction

Cost reduction studies across off-highway, agricultural, construction, and mining platforms

ASI Engineering delivers platform-level cost reduction by tearing down full off-highway systems, modelling them in xcPEP, and identifying hidden savings through real manufacturing logic. Every simulation reflects actual plant operations, helping teams reduce cost with confidence.

Off-Highway Vehicles

Benchmarking & Cost Reduction

Engineering-led cost savings across enclosures, motors, insulation, wiring, and controls—powered by teardown data, detailed cost models, and real manufacturing logic.

Teardown benchmarking

Of Customer's & Competitor's Vehicles

Should Costing

Of Customer's & Competitor's Vehicles

Cost Reduction Idea Generation

By analyzing cost gaps between customer's and competitor's vehicles.

Off-Highway Cost Reduction

Why it matters now more than ever

Cost reduction has become a priority across agricultural, construction, and mining equipment due to tightening emissions norms, fluctuating input prices, and growing pressure from lower-cost competitors. Most programs still rely on top-down targets or BOM-level tracking, which miss true cost drivers hidden inside process flow, design decisions, and manufacturing complexity. Without detailed visibility at the part and process level, cost reduction remains inconsistent and reactive.

You can’t reduce cost by just tracking it. You need to break it down and understand what’s behind it.

Our Approach

Engineering-Led Should Costing with xcPEP

Our approach to cost reduction starts by tearing down your part alongside a competitor’s and understanding what drives the cost. We do not just report the total. We look at every part, every process, and every design choice to find where the cost can actually be reduced. This work is done by ASI Engineering using real manufacturing logic. Below are some of the major cost drivers we have seen repeatedly in off-highway platforms and where most of the savings usually come from.

Optimizing weight and complexity

Castings and Forgings

We find most savings by reducing unnecessary weight and simplifying casting or forging shapes. Minor adjustments to thickness or material choice often significantly cut production cost.

Streamlining tolerances and setups

Machined Components

Savings typically come from relaxing overly tight tolerances and optimizing machining setups. Adjusting unnecessary precision levels directly reduces machining time and cost.

Reducing labor and complexity

Welding and Assembly

We regularly achieve savings by simplifying weld joints and assembly sequences. Reducing manual labor through better design and automated welding cuts overall production expenses.

Consolidating suppliers and designs

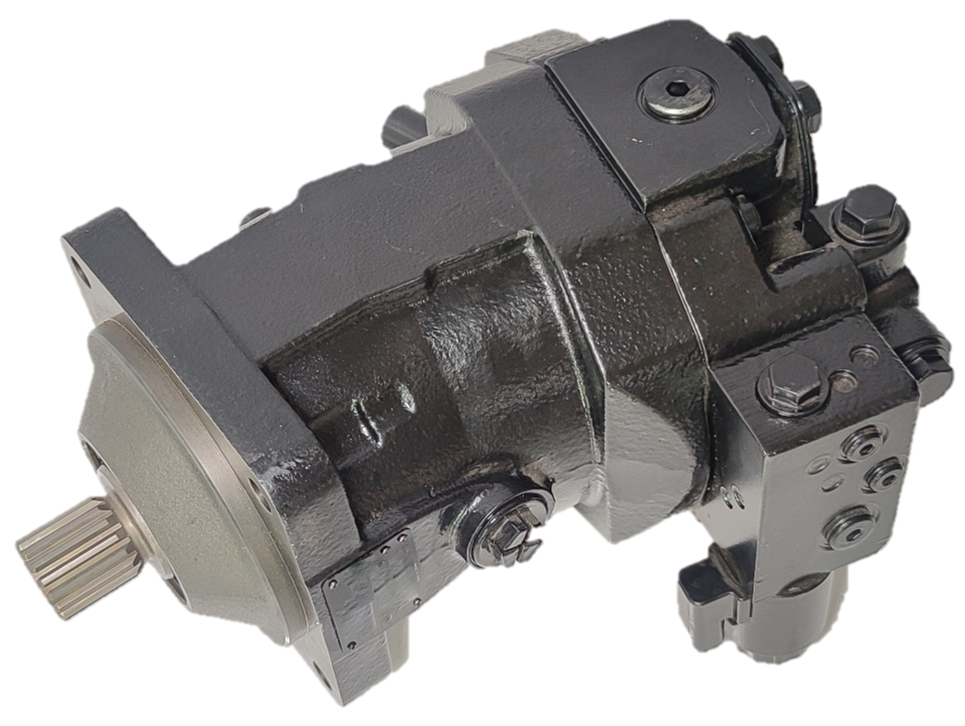

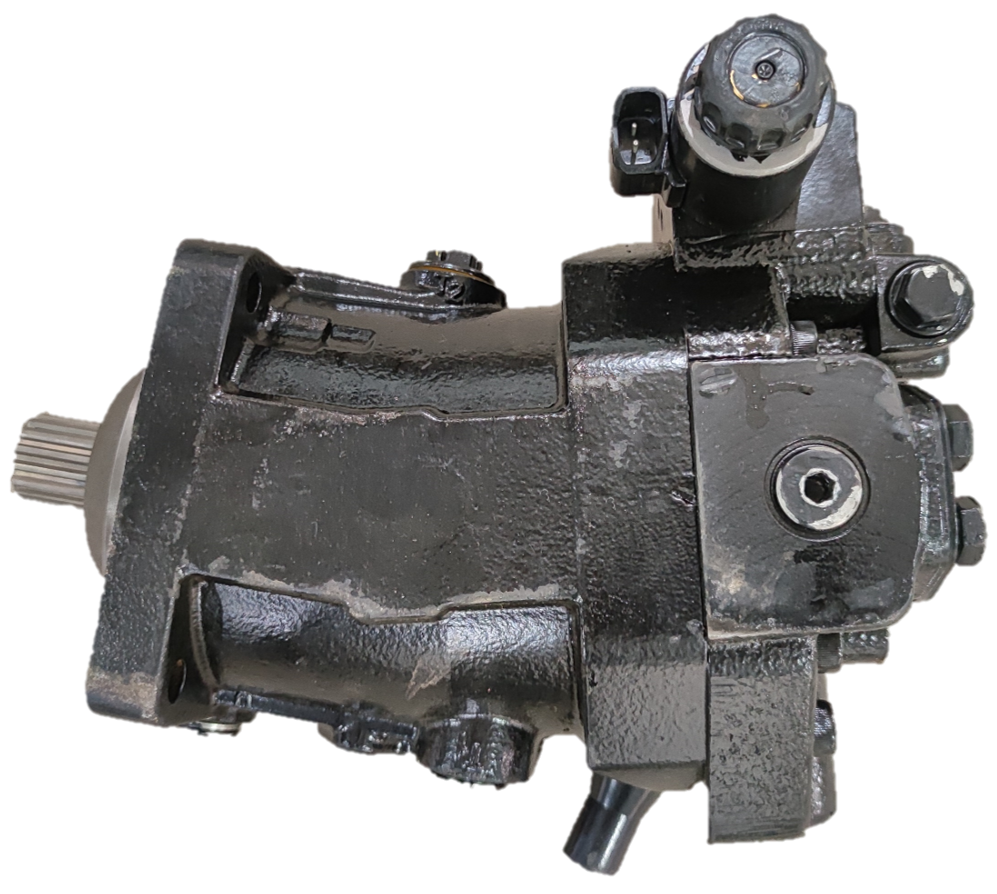

Hydraulic Systems

Major savings usually arise from consolidating suppliers and standardizing hydraulic components. Eliminating redundant or overly complex designs significantly lowers costs.

Simplifying design and processes

Powertrain Components

Most savings in powertrain components come from eliminating unnecessary complexity in gear designs and assembly processes. Selecting more cost-effective materials also significantly reduces expenses.

Reducing material and complexity

Chassis & Structural Frames

We typically identify savings by highlighting excess material and unnecessary fabrication steps, directly reducing cost without affecting durability.

Should Costing in xcPEP

Covers detailed should costing of every part's raw material, manufacturing process and overheads.

Off-Highway Costing in

xcPEP

xcPEP is tailored specifically for off-highway vehicles where precision matters, manufacturing processes are complex, and cost visibility is critical. Using detailed teardown-derived data, xcPEP maps exact material usage, machining operations, welding processes, assembly steps, and supplier-specific cost variables.

Every component—from castings, forgings, and machined parts to hydraulics and electrical harnesses—is costed using actual manufacturing logic and accurate regional data from xcPROC. Process flows reflect realistic shop-floor scenarios, enabling precise cost analysis and scenario simulation.

Designed for tractors, construction machinery, mining equipment, and specialized off-highway vehicles, xcPEP allows detailed component-level costing and reliable decision-making across product lines and design variants.

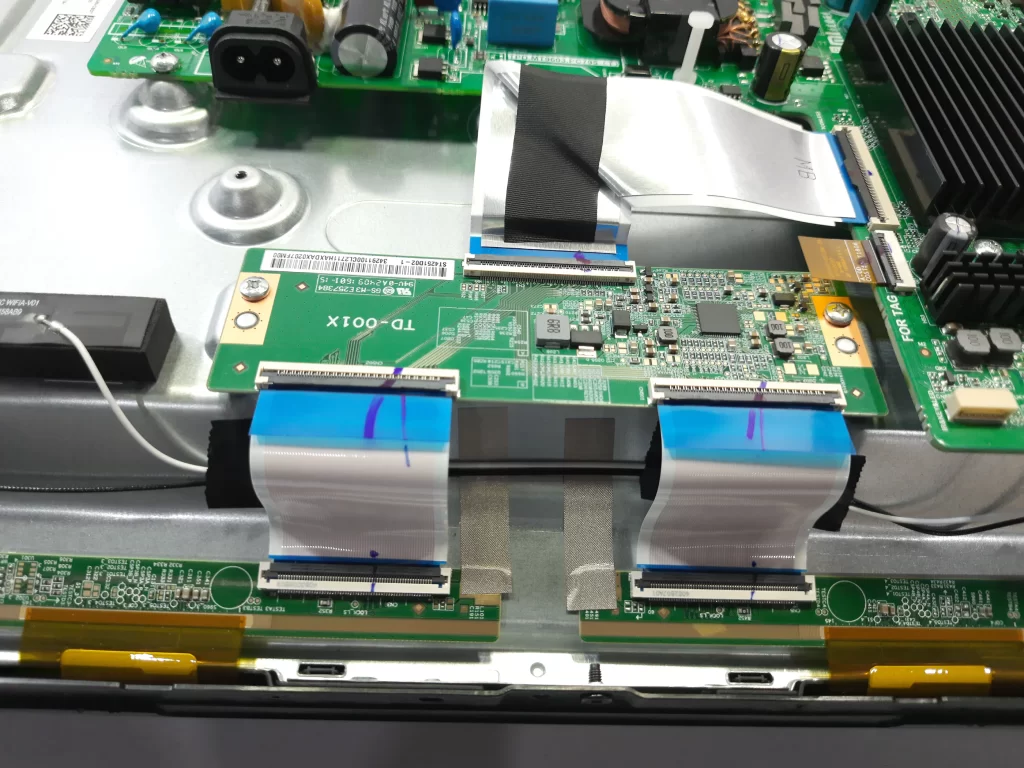

In depth costing of PCB

In depth costing of mechanical parts

Massive Library of Cost Models

With xcPEP, every machined and fabricated part is costed using actual plant data. The platform highlights inefficiencies in machining cycles, tolerances, and fabrication steps, helping teams focus on what can be streamlined or redesigned for lower cost.

Precise Machine Database

ASI Engineering leverages xcPEP’s process and machine database to use accurate regional machine hour rates and process costs. This precision ensures that savings identified are based on real-world manufacturing logic, not just averages.

Scenario Costing: Instantly compare suppliers or regions

xcPEP allows users to simulate supplier or region changes in one click. By shifting sourcing between regions or suppliers, teams can instantly see how costs change, making it easier to make fact-based sourcing decisions and unlock new savings.

Analyse data in depth

xcPEP makes it possible to analyze costs down to every process and part. ASI Engineering drills into this data to find inefficiencies and excess, ensuring no opportunity for cost reduction is missed.

xcPEP

xcPROC

Comprehensive & Detailed Data Mapping

By leveraging machine learning models built in xcPEP

ASI Engineering uses purpose-built tools developed in-house to enable fast and structured teardown of off-highway vehicle systems and components. These systems are designed to capture detailed part-level physical and geometric data such as dimensions, material thickness, weld lengths, and machining features, without relying on manual measurement or guesswork.

The captured data flows directly into xcPEP, where it enables side-by-side cost comparison between your vehicle platform and competing machines. This structured input allows ASI Engineering to trace cost differences back to design choices, manufacturing methods, or material usage, and to generate clear, actionable ideas to reduce cost while maintaining performance and durability.

Detailed Data Mapping of -

Mechanical Components

For mechanical parts in off-highway vehicles, ASI Engineering captures detailed physical data during teardown to help identify cost saving opportunities. To make this process faster and more consistent, we use in-house tools that accurately measure dimensions such as length, width, thickness, and surface area for large components like structural frames, brackets, and housings. This data is then used inside xcPEP to compare your platform with competitor vehicles, making it easy to see which design or manufacturing choices are driving up cost.

Detailed Data Mapping of -

Electrical Components

To support cost reduction in off-highway vehicles, ASI Engineering uses automated tools to capture detailed part-level data from wiring harnesses, control panels, and electrical assemblies. These systems quickly identify and log every connector, terminal, relay, and fuse—without relying on drawings or manual entry. Each component’s type, location, and quantity are processed into xcPEP, where the data is linked with actual sourcing rates and assembly process parameters.

This enables us to build structured, evidence-backed BOMs that highlight where your electrical system is adding unnecessary cost compared to competitor platforms. Whether the goal is to reduce connector count, simplify harness routing, or select more cost-effective components, the captured data helps teams identify clear cost-saving opportunities while maintaining system reliability.

Cost Reduction Idea Generation in xcPEP

Software & Data Driven

Costing of Own Product

ASI Engineering models your off-highway vehicle in detail, creating a clear cost baseline for every part and assembly.

Costing of Competitor Product

We cost competitor vehicles using the same structured approach, enabling direct, apples-to-apples comparison.

Idea Generation by Comparison

xcPEP pinpoints specific areas where your platform can save cost by comparing it directly to the competition.

Cost Reduction Channels

generated by xcPEP

DeContent

Spotting and removing unnecessary features, parts, or over-specification that do not impact core performance, such as extra fasteners, brackets, or redundant covers.

Alternate Material

Switching to more cost-effective or locally sourced materials where possible, like moving from specialty alloys to standard steel or using high-strength plastics for non-critical components.

Alternate Supplier

Comparing and selecting suppliers who offer better pricing or efficiency, including shifting to vendors in different regions or consolidating orders to increase volume discounts.

Alternate Manufacturing Process

Exploring new manufacturing methods—such as replacing intensive machining with fabrication, or adopting more automated processes—to lower production costs.

Routing & Packaging

Improving how parts are routed through production and packaged for shipping or assembly, with savings found in reduced handling, optimized layouts, or smarter packaging choices.

Knowledge transfer workshop

With your engineers and managers at your premises

How are we different?

At our core, we build cost engineering technology. Our primary focus is on xcPEP and xcPROC, while our engineering services are designed to support and accelerate customer adoption of our ecosystem.

Column Title

BOM based tools

Management Consultants

xcPEP + ASI Engineering

Technology for electrical parts costing

Technology for electronics parts costing

Technology for mechanical parts costing

Child part BOM cost management

Manufacturing process detailed costing

Overhead detailed assumptions

Automated data mapping for benchmarking

Experience based idea generation

Data based comprehensive idea generation

Off-Highway Cost Lab

Product Studies

Cost engineering projects by the ASI Engineering Team.

This section features detailed studies from projects carried out by ASI Engineering on off-highway platforms. Every teardown, photograph, and cost model shown here is the result of our own independent work. The aim is to create transparent, structured cost models that capture real manufacturing logic.

These studies span systems such as powertrain, hydraulics, chassis, frames, sheet metal, and electricals—showing how precise inputs and practical assumptions lead to robust costing outcomes. Each model is developed by ASI using process flows and routing logic that reflect how these machines are actually built in the field.