Advanced Should Costing for Tractors, Heavy & Construction Equipment

Executed by ASI Engineering using xcPEP, Should Costing Software.

Should costing plays a critical role in off-highway programs—especially where high part costs, low production volumes, and sourcing spread across multiple regions make cost control particularly challenging.

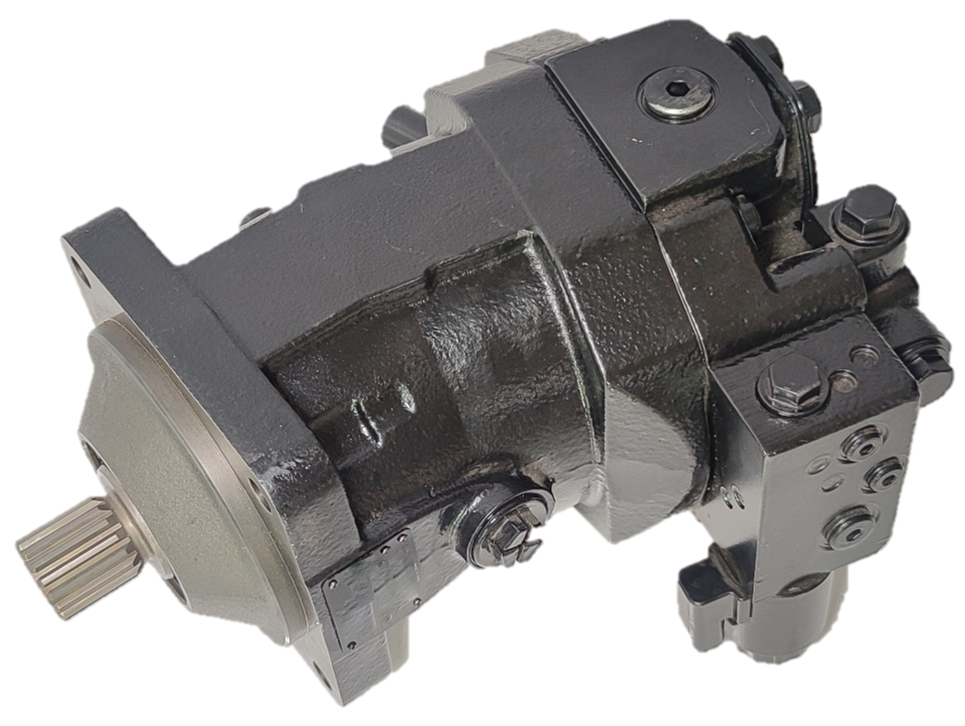

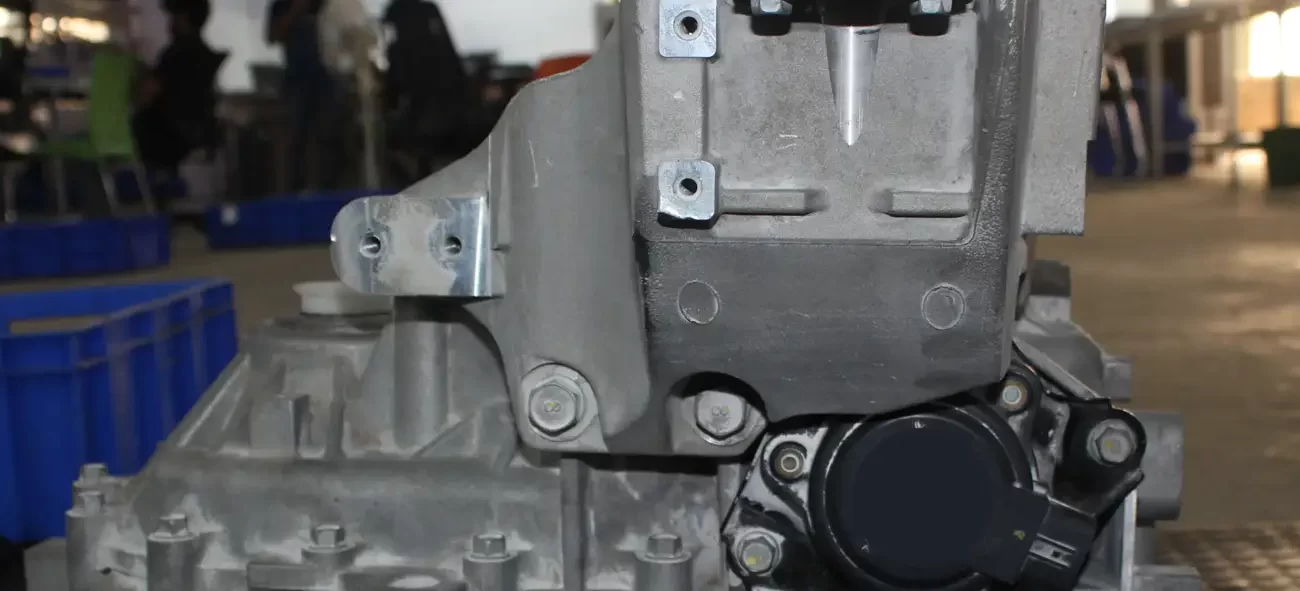

Off-highway platforms—including excavators, tractors, construction equipment, and heavy machinery such as wheel loaders and mining trucks—are built through diverse, cost-intensive manufacturing processes. Precision-dependent operations like heavy casting, welded structures, hydraulic machining, and multistage drivetrain fabrication introduce cost drivers that vary with batch size, routing, and geography. These drivers are not captured in BOM rollups or spreadsheet tools, making structured should costing methodology essential—grounded in real manufacturing process logic and region-specific input cost data.

ASI Engineering undertakes complete should costing projects for OEMs and suppliers—delivering part-level cost data, process logic, and manufacturing breakdowns using detailed should cost models. Our team supports sourcing and design decisions with actionable insights for tractors, heavy equipment, and construction machinery.

Challenges and limitations of legacy tools in -

Off-Highway Should Costing

Off-highway vehicles use large castings, welded frames, hydraulic systems, and complex drivetrains. Parts are built in low to mid volumes, with cost driven by setup time, scrap, inspection, and regional sourcing. This mix of processes and production realities makes costing difficult to generalize.. Should costing for tractors is especially difficult because parts often span low volumes, welded sub-assemblies, and casting-heavy drivetrains—introducing high cost variability across plants, suppliers, and regions.

Traditional tools cannot handle this complexity. Excel breaks down when routing or region changes. Legacy software depends on clean CAD and fixed templates that do not match off-highway manufacturing. Consulting reports offer one-time estimates but cannot support internal teams on an ongoing basis.

ASI Engineering approaches this differently. Every project we execute is built on process level understanding and real-world inputs. We create models from the ground up, based on actual manufacturing operations and region-specific rates. Routings are assigned with care, reflecting how the part would be made in practice, not in theory. We account for cycle time, scrap, setup, and labour variation to reflect how cost behaves across suppliers, volumes, or geographies. The result is a structured, reusable model that gives sourcing and engineering teams a reliable cost reference, not just a one time number.

Consulting reports, legacy tools, and spreadsheets may give you a number, but not the real cost. ASI Engineering shows how the part is actually made, and what it should truly cost.

The Same Part Can Be Made in Different Ways

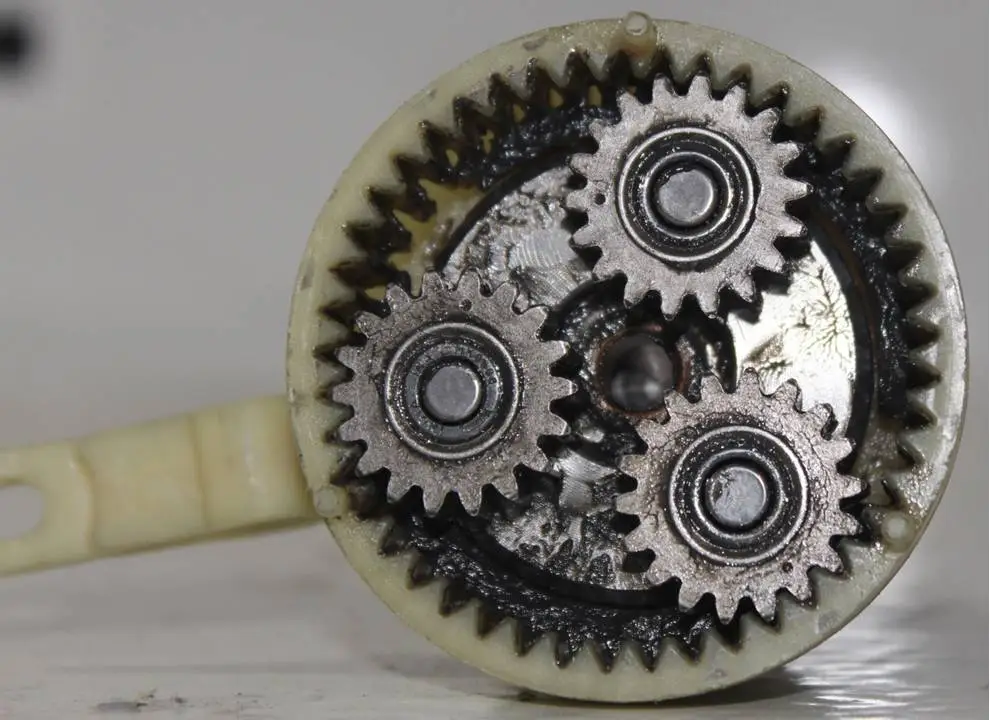

In off-highway manufacturing, the same part can be made using different combinations of processes depending on the plant, available machinery, tooling setup, and batch size. A gearbox housing might be cast in one case or machined from solid in another. A frame may be fabricated from plate in one plant or assembled from cast modules in another. There is no single fixed path to production.

This variability makes it impossible to use a templated costing approach. Tools that rely on predefined routings or generic formulas do not capture how the part is actually made. Every operation sequence must be built from real manufacturing logic — which Excel, static BOM tools, or high-level reports cannot replicate. This variability is a major reason why structured should costing for tractors is essential—ensuring plant-specific processes and cost drivers are captured accurately.

Production Volume Drives Cost Behavior

Not all off highway parts are built in small quantities. Common components like housings or transmissions may run in high daily volumes, while others such as boom arms, brackets, or model specific hydraulics are produced in smaller batches. At lower volumes, setup time, fixture cost, and overhead absorption start to dominate cost.

Many costing tools assume stable, high volume production where cycle time and material drive pricing. But off highway programs often combine both scales, and unless costing accounts for volume effects, the output remains disconnected from how cost actually behaves in production. This is particularly important in should costing for heavy equipment, where cost models must reflect volume-sensitive operations like welding and assembly of structural parts.

Region and Plant-Level Inputs Matter

The cost of the same part changes drastically depending on where it is made. Hourly wages, energy tariffs, machine depreciation, indirect labour ratios, and even downtime norms vary by country and plant. A housing machined in Europe does not cost the same as one machined in India, even if the process steps are identical.

Most tools either apply standard rates or depend on user inputs that rarely get updated. Without region-specific data for each process and operation, even a detailed cost structure becomes disconnected from sourcing reality.

Accurate should costing for construction equipment requires region-specific cost inputs to reflect real manufacturing conditions across global supplier bases.

Most Off-Highway Parts Involve More Than One Process

Off-highway parts are often built through a mix of casting, welding, machining, painting, and assembly — sometimes all in the same component. For example, a bracket may start as a forged blank, then be machined, then welded into a larger structure, then painted and tested. Each step adds cost in a different way.

Spreadsheets and BOM-based systems cannot track which operation adds how much value, or how scrap, rework, or tool life affect total cost. Every process step must be defined, measured, and costed. Without this granularity, there is no way to know what to challenge, what to optimise, or what to negotiate. This is especially true in should costing of construction equipment, where multi-process parts demand detailed visibility into real manufacturing logic.

PDFs and Excel Files Cannot Handle Changing Assumptions

Costing in off highway programs is not a one time exercise. As designs evolve, sourcing regions shift, and suppliers change, the underlying assumptions in a cost model must be updated. A single quote validation or benchmark may help in the short term, but it cannot support long term program decisions.

Consulting reports are usually shared as static PDFs or Excel summaries. They are not built for reuse, simulation, or adjustment. Once any design or rate input changes, the report becomes obsolete, and teams are forced to start over. Without a structured and editable approach, costing quickly becomes disconnected from the program it was meant to support.

Off-Highway Should Costing in xcPEP

Should costing based on actual manufacturing steps, batch sizes, and regional inputs.

How ASI Engineering Executes Off-Highway Costing

in xcPEP

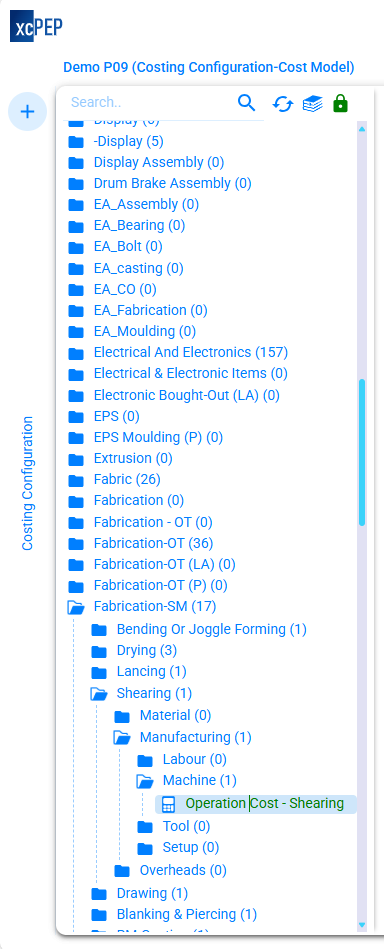

xcPEP is built to support detailed cost modeling for off-highway systems, where components are large, structurally complex, and produced in variable volumes. The platform uses data derived from teardown, drawings, or CAD and structures cost models based on actual operations with region-specific inputs from xcPROC. xcPEP is a cloud-native should costing software, enabling teams to access and collaborate on models from anywhere without infrastructure dependencies.

Each part, such as a loader arm, axle housing, or hydraulic assembly, is broken into real manufacturing steps with cycle time, scrap, labour, and overhead configured per plant. ASI Engineering executes this inside xcPEP using factory specific process logic, not templates or rollups.

The result is a clear, process-based cost model that teams can use for quote validation, design reviews, make versus buy decisions, and cost reduction. xcPEP enables consistent analysis across parts and variants throughout the program.

Operation wise costing for every part

Verified Inputs Based on Region, Plant, and Process

ASI Engineering configures every cost model inside xcPEP using verified data pulled directly from xcPROC. This includes region-specific values for raw materials, machine hour rates, and labour costs, as well as plant-level parameters such as setup time, scrap rates, indirect labour, and machine availability.

Cycle time and operation-specific inputs are not assumed — they are mapped based on real equipment and process profiles from the selected plant or geography. This level of detail ensures that a part made in India, Brazil, or Europe is costed using the actual rates and production logic of that location. No external rate sheets or general averages are used. All data is structured, validated, and traceable.

In depth costing of mechanical parts

ASI Engineering builds cost models for structural and mechanical components like arms, brackets, mounts, frames, and carriers. Each part is analyzed for material type, process sequence, and plant-specific production details. Operations such as flame cutting, plate bending, jig welding, rough and finish machining, and painting are mapped precisely to reflect shop floor conditions

Massive library of cost models

xcPEP maintains a structured collection of part-level cost models for off-highway systems, created by ASI Engineering Team These models reflect real production logic and can be adapted for variants or similar platforms.

Run What If Scenarios for Volume, Region, or Process Changes

ASI Engineering uses xcPEP to simulate real world cost changes without rebuilding the model. Whether switching from a European to an Indian supplier, changing batch size from 3000 to 500, or replacing machining with fabrication, the model updates automatically.

Inputs like material rates, machine availability, labour cost, and overhead structure adjust based on the selected geography or production method. This helps sourcing and engineering teams compare options quickly and understand the cost impact of each change before committing.

xcPEP

xcPROC

Should Cost Models for Tractors, Heavy & Construction Equipment

Built by ASI Engineering using real manufacturing logic

ASI Engineering builds part-level cost models inside our should cost analysis software, xcPEP using real manufacturing logic. Each model is configured based on actual production steps such as casting, machining, welding, molding, or painting. Inputs like machine time, labour, material, and scrap are assigned per process and per geography.

Should Cost Models for Casting Parts in Tractors & Construction Equipment

Sand Casting

- Green Sand Casting

- Resin Sand Casting

- Shell Moulding

- Manual Core Assembly

Die Casting

- Gravity Die Casting

- High-Pressure Die Casting (HPDC)

- Low-Pressure Die Casting (LPDC)

- Trimming & Degating

Shell Mould Casting

- Precision sand shell molding

- Used for control arms and brake parts

- Better dimensional accuracy

Investment Casting

- Lost wax process

- Used for small complex parts

- Thin walls & fine features

Centrifugal Casting

- Rotational casting for cylinders

- Common for sleeves and liners

- High material density

Permanent Mold Casting

- Reusable steel molds

- Used for aluminum hubs and mounts

- Higher surface finish than sand

Should Cost Models for Machined Components in Heavy & Construction Equipment

Turning & Facing

- Precision Turning

- Shoulder Facing

- Grooving & Parting

- Live Tooling

Milling & Drilling

- 3-Axis Milling

- 5-Axis Milling

- Through-Coolant Drilling

- Thread Tapping

Boring & Finishing

- Boring Bar Operations

- Reaming

- Surface Grinding

- Dimensional Inspection

Should Cost Models for Welded Parts in Tractors & Construction Machinery

Cutting

- Laser Cutting

- Plasma Cutting

- Oxy-Fuel Cutting

- Waterjet Cutting

Forming

- Press Brake Bending

- Tube Bending

- Roll Forming

- Swaging

Welding

- MIG/MAG Welding

- TIG Welding

- Manual Arc Welding

- Robotic Welding

Finishing & Fixtures

- Weld Fixture Setup

- Grinding & Surface Prep

- Leak Testing

- Assembly Fit Checks

Should Cost Models for Sheet Metal Parts in Tractors & Heavy Equipment

Blanking & Shearing

- Hydraulic Shearing

- NC/CNC Blanking

- Progressive Die Blanking

- Laser Sheet Cutting

Stamping Operations

- Deep Drawing

- Piercing & Notching

- Embossing

- Coining

Bending & Rolling

- Press Brake Bending

- Roll Bending

- Flanging

- V-Die Bending

Tooling & Setup

- Die Setup & Maintenance

- Jig & Fixture Loading

- Tool Changeover

- Batch Setup Time

Should Cost Models for Rubber Moulded Parts in Construction & Agricultural Equipment

Compression Moulding

- Hydraulic Compression

- Transfer Moulding

- Preformed Blank Moulding

- Closed-Mold Curing

Extrusion Moulding

- Hot Feed Extrusion

- Cold Feed Extrusion

- Steam Vulcanization

- Autoclave Curing

Should Cost Models for Plastic Injection Moulded Parts in Construction & Agricultural Equipment

Hot Runner Tooling

- Valve-Gate Hot Runners

- Heated Manifold Systems

- Sequential Valve Control

- Multi-Cavity Dies

Cold Runner & Inserts

- Cold Runner Tooling

- Insert Moulding

- Overmoulding

- Unscrewing Mechanisms

Should Cost Models for Electrical Parts & Wiring Harnesses in Off-Highway Equipment

Wiring Harnesses

- Cable Cutting & Stripping

- Terminal Crimping

- Connector Assembly

- Harness Wrapping

PCB & Control Modules

- PCB Assembly

- Component Soldering

- Potting & Encapsulation

- Functional Testing

Switches & Indicators

- Actuator Assembly

- LED Integration

- Panel Mounting

- Sealing & Potting

Electrical QC

- Continuity & Insulation Tests

- Signal Mapping

- Connector Pull Tests

- Visual & Electrical Inspection

Advanced Data Capture Hardware

Developed by ASI to capture accurate part-level inputs for off-highway cost modeling.

Off-highway parts are often large, structurally complex, and difficult to measure accurately using manual tools. ASI has developed custom imaging and measurement systems to digitize key teardown steps and standardize the extraction of input data for xcPEP, our proprietary should-cost analysis software.

By automating steps like component identification, 3D bounding box measurement, and projected area capture, these systems reduce lead time, improve repeatability, and ensure input accuracy for cost modeling. The setup is tuned for low-volume, high-complexity assemblies where data reliability is critical.

AI-Based Component Identification for PCBs

Even in heavy equipment, PCBs and electronic subassemblies are used for control systems, ECUs, and diagnostic modules. Identifying components manually is time-consuming and error-prone, especially in multi-layer boards. In off highway should costing, these electronic assemblies present a unique challenge due to their dense layouts and component diversity. ASI uses a calibrated imaging system to scan each board and automatically classify components such as ICs, resistors, and connectors. Each part is tagged digitally, and the output BoM is structured for cost modeling inside xcPEP using the xcPROC database, which powers xcPEP our should costing modelling software for complex assemblies.

Bounding Box Dimension Capture System

Parts like fabricated loader arms, cast axle housings, fuel tanks, and hydraulic reservoirs often have irregular shapes that are hard to measure accurately. Caliper or tape-based measurement introduces significant error at scale. ASI uses a contactless laser setup to capture full bounding box dimensions of large components. The part is positioned inside a reference enclosure and scanned for length, width, and height. These dimensions feed directly into xcPEP to estimate blank size, packaging, or raw material weight.

Projected Area Capture System

Many off-highway components such as side panels, battery covers, and guard plates require projected area to estimate blank weight, laser cutting time, or fabrication cost. This becomes especially critical in construction equipment should costing, where accurate blank estimation directly impacts material cost and nesting efficiency. ASI automates this by placing the part against a backlit grid and capturing its silhouette using a calibrated camera. The area is calculated in real dimensions and pushed to xcPEP to support costing for stamping, laser cutting, or CNC nesting.

Outcomes of Off-Highway Should Costing

Delivered by ASI Engineering

When ASI Engineering executes should costing for off-highway components, the outcome is not just a part level should cost. It is a structured model that supports better decisions across sourcing, design, and manufacturing. Each model is built inside xcPEP, our should cost model software, using actual manufacturing logic, enabling teams to trace, reuse, and act on cost with clarity.

Here are some of the typical outcomes delivered to off-highway teams through projects executed by ASI Engineering.

Target Costing During Product Development

During early program phases, ASI Engineering estimates cost based on 2D Drawings, using xcPEP our should-cost analysis tool. This helps design teams assess feasibility against cost targets before locking design decisions.

Competitor Product Benchmarking

ASI Engineering tears down and costs competitor assemblies to identify cost structure differences. These models are used by commercial and leadership teams to understand sourcing choices and pricing strategy of other OEMs.

Localisation Feasibility Analysis

ASI Engineering uses xcPEP, our cloud-native should cost software platform to simulate how cost behaves when production is shifted across regions. This allows OEMs to compare Indian, European, or Latin American sourcing options without reworking the entire model.

Alternate Supplier Identification

Where single sourcing creates risk, ASI Engineering performs should costing to identify lower-cost, viable alternatives. These insights help sourcing teams pursue cost down opportunities without compromising technical integrity.

Scenario Costing for Design and Volume Shifts

Whether the question is design simplification, volume ramp up, or process change, ASI Engineering uses xcPEP our cloud-based should cost model tool, to simulate cost impact quickly. These what-if scenarios help teams plan changes without losing cost visibility.

How are we different?

Comparing ASI Engineering + xcPEP with legacy costing methods

Most off-highway costing today is done using Excel models, BOM rollups, or static consulting reports. These approaches either oversimplify how cost is built or produce one-time outputs that cannot be reused. ASI Engineering solves this by combining actual manufacturing knowledge with a structured cost platform. Every part is broken down into real operations, and cost is built inside xcPEP using region-specific rates and process logic. The result is transparent, reusable costing — not estimates or assumptions.

Column Title

Spreadsheets

BOM based tools

Management Consultants

xcPEP + ASI Engineering

Real manufacturing process logic

Plant-specific input configuration

Region-specific cost rates

Transparent, repeatable costing

Operation-level cost modeling

Live scenario simulation (volume, region)

Digital reuse across parts and programs

Cloud-based access and collaboration

Continuous engineering support

Use Cases of xcPEP in Off-Highway

Deployed across sourcing, cost, and engineering teams — from in-house cost lab setup to supplier negotiations.

xcPEP is used by off-highway OEMs and suppliers to bring structure and repeatability into part-level costing. As a robust should cost solution, it supports both internal cost teams and joint engagements with ASI Engineering. Whether deployed inside a cost control team or run jointly with ASI Engineering, the platform enables practical decision-making across programs.

Below are few use cases where xcPEP has been deployed in real off-highway projects.

In-House Cost Lab Setup

xcPEP was deployed to build a cost lab inside a global construction equipment OEM, supporting parts like loader arms, axle housings, and fabricated enclosures. ASI Engineering configured the platform, migrated legacy Excel cost models, and structured the client’s BOM hierarchy. A core team was trained to run new part costing, quote validation, and alternate supplier analysis directly inside xcPEP. Today, the OEM independently operates the lab, with ASI providing database updates and support.

Should Costing for New Part Development

xcPEP, our should cost analysis tool, was deployed by an off-highway equipment manufacturer to support should costing during early part development. ASI Engineering worked with engineering and sourcing teams to cost key components such as loader arms, axle housings, and structural weldments before final supplier quotes were received.

Cost estimates were built using real manufacturing steps and inputs for region-specific machine, labour, and material rates. This helped define internal cost targets early and reduced reliance on supplier quotes or external benchmarks.

Fact Packs for Supplier Negotiations

xcPEP was deployed by an off-highway OEM to support cost-backed supplier negotiations. ASI Engineering built structured cost references for castings, weldments, and machined parts based on actual production operations such as pattern making, rough and finish machining, fixture setup, and painting.

The results were compiled into negotiation-ready fact packs, helping sourcing teams validate supplier quotes, identify gaps, and negotiate with clear visibility into cost drivers and process assumptions.

Competitor Cost Benchmarking

xcPEP was used to benchmark the cost of a competitor’s tractor for a global off-highway OEM. ASI Engineering performed a structured teardown and built detailed cost models for critical systems such as axle housings, transmission cases, and hydraulic components, capturing inputs on casting quality, machining cycles, welding effort, and paint application.

The result was a structured cost comparison at part and system level, helping the customer identify cost gaps, design inefficiencies, and opportunities for sourcing or value engineering improvement.

xcPEP Off-Highway Cost Lab

Product Studies

Cost engineering projects executed internally by ASI Engineering team.

This section features cost studies built entirely by ASI Engineering using real manufacturing logic. Each teardown, process breakdown, and cost model is based on our own independent work—conducted without client data.

These studies focus on off-highway systems such as loader arms, axle housings, hydraulic blocks and fabricated frames. Every model is constructed inside xcPEP using detailed process steps and plant-level inputs. Powered by our should cost modelling software, the goal is to show how accurate, well-structured costing can reflect how parts are actually built and help drive meaningful cost decisions.