xcPEP Should Cost Analysis Software

Should Costing You Can Defend, Cost Models You Can Trust.

xcPEP

Should Cost Analysis Software

What is xcPEP?

xcPEP is a next-generation Should Costing platform built to solve real-world costing challenges.

It enables teams to estimate part costs using manufacturing logic, regional rates, and technical parameters without relying on static averages or black-box assumptions. xcPEP is industry-agnostic, role-adaptive, and supports both individual costing tasks and large-scale digital transformation of cost functions. With full transparency into calculations and inputs, it helps teams defend decisions, align cross-functionally, and negotiate with confidence.

Plastic Moulding

- Film Packaging

- Polyethylene (PE) Films

- Polypropylene (PP) Films

- Polyethylene Terephthalate (PET) Films

- Biaxially Oriented Polypropylene (BOPP)

- Cast Polypropylene (CPP)

- Biaxially Oriented Polyester (BOPET)

- Amorphous Polyester (APET)

Thermoforming

- Vacuum Forming

- Pressure Forming

- Drape Forming

- Twin-Sheet Forming

- Foam Moulding

- Structural Foam Moulding

- Architectural Foam Moulding

- Foam Crown Moulding

- Stucco Foam Trim

- EPS Shape Moulding

Extrusion Moulding – Plastic & Ceramic

- Direct (Forward) Extrusion

- Indirect (Reverse) Extrusion

- Hydrostatic Extrusion

- Blown Film Extrusion

- Sheet/Film Extrusion

- Tubing Extrusion

- Coextrusion

- Extrusion Coating

Plastic Rota Moulding

- Clamshell Machine

- Shuttle Machine

- Carousel Machine

Injection Moulding – Thermoplastic

- High-Pressure Injection

- Micro Injection Moulding

- Gas-Assisted Injection

- Thin-Wall Packaging Moulding

Injection Moulding – Thermoset

- Transfer Moulding

- Compression Moulding

- Reaction Injection Moulding (RIM)

- Blow Moulding

- Extrusion Blow Moulding

- Injection Stretch Blow Moulding

- Accumulator Head Blow Moulding

Rubber Moulding

- Compression Moulding – Rubber

- Hydraulic Compression Moulding

- Transfer Compression Moulding

- Preformed Rubber Blank Moulding

- Closed Mold Curing

- Rubber Sheet Moulding

- Extrusion Moulding – Rubber

- Hot Feed Extrusion

- Cold Feed Extrusion

- Microwave Curing Extrusion

- Steam Vulcanization Extrusion

- Salt Bath Curing

- Autoclave Curing

- Injection Moulding – Rubber

- Liquid Injection Moulding (LIM)

- Vacuum Injection Moulding

- Rubber Transfer Injection

- Cold Runner Injection Moulding

- Injection Moulded Seals & Gaskets

- Extrusion Moulding – Rubber & Plastic

- Dual Extrusion (Hard-Soft Combinations)

- Co-extruded Weather Seals

- TPV and EPDM Hybrid Extrusion

- Rubber-Plastic Strip Profiles

- Edge Trim Extrusion

Metal Forming

- Cold Forging

- Cold Heading

- Cold Extrusion

- Cold Impact Extrusion

- Coining

- Cold Roll Forging

Ferrous Casting – Sand Casting

- Green Sand Casting

- Resin-Bonded Sand Casting

- No-Bake Sand Casting

- Shell Moulding

- Lost-Foam Casting (Ferrous)

Hot Forging – Gear

- Upset Forging of Gear Blanks

- Cogging

- Skiving & Burnishing

- Finish Forging

Hot Forging – Crankshaft

- Preform Forging

- Rotary Forging

- Impression-Die Forging

- Finish Forging & Trimming

- Powder Metallurgy

- Cold Press & Sinter

- Hot Isostatic Pressing (HIP)

- Metal Injection Molding (MIM)

- Powder Forging

Spring – Cold Wound

- Compression Spring Coiling

- Extension Spring Coiling

- Torsion Spring Coiling

- Wire Straightening & Stress Relieving

Spring – Hot Wound

- Hot Coil Winding

- Ring Spring Forming

- Shot Peening

- Annealing

Substrate – Metallic

- Aluminum Substrate Bonding

- Copper Core Substrates

- Metal-Insulated Substrates (IMS)

- Heat-Sink Metal Cores

- Zinc Casting – HPDC

- Hot-Chamber Die Casting

- Cold-Chamber Die Casting

- Vacuum Die Casting (Zinc)

- Squeeze Casting

Zinc Casting – GDC

- Tilt-Pour Gravity Casting

- Low-Pressure GDC

- Slush Casting

- Permanent-Mould Casting

Aluminium Casting – HPDC

- Cold-Chamber HPDC

- Hot-Chamber HPDC

- Vacuum HPDC

- High-Pressure Die Casting (Al Alloys)

Aluminium Casting – GDC

- Tilt-Pour Permanent-Mould Casting

- Slush Casting

- Low-Pressure Permanent-Mould

- Semi-Solid Rheo Casting

- Brass Casting – LPDC

- Bottom-Fill LPDC

- Counter-Gravity LPDC

- Semi-Solid LPDC

- Hot-Chamber LPDC

Brass Casting – GDC

- Tilt-Pour Gravity Casting

- Permanent-Mould GDC

- Centrifugal Casting (Brass)

- Sand-Mould Gravity Casting

Hot Forging – Roll

- Cogging-Mill Roll Forging

- Controlled Rolling

- Ring Rolling

- Scale-Breaker Rolling

Hot Forging – Closed Die

- Impression-Die Forging

- Flashless Forging

- Flash-Type Forging

- Precision Forging

Metal Fabrication

- Fabrication – Sheet Metal

- Laser Cutting

- Shearing

- Press Brake Bending

- Punching & Notching

- Roll Forming

- Deburring & Finishing

Machining – Gear

- Gear Hobbing

- Gear Shaping

- Gear Grinding

- Gear Broaching

- Gear Heat Treatment

- Fabrication – Structural & Others

- Steel Beam & Plate Welding

- Pipe & Tube Spooling

- Chassis & Frame Assembly

- Sheet Lamination

Metal Hose Assembly

- Spiral‐Wound Hose

- Braid Reinforced Hose

- Corrugated Hose

- PTFE Lined Hose

- Swaging & End Fitting

Stamping – Progressive Die

- Multi-station Strip Feeding

- Cutting, Forming & Piercing

- Progressive Coil Processing

- Stamping – Transfer Die

- Individual Blank Feeding

- High-Speed Compound Operations

- Automated Part Transfer

Stamping – Compound Die

- Simultaneous Cutting & Forming

- Deep Draw & Embossing

- High-Tonnage Presses

Cutting & Ablation

- Laser Cutting

- Plasma Cutting

- Waterjet Cutting

- Oxy-Fuel Cutting

- Welding & Joining

- MIG / MAG Welding

- TIG Welding

- Spot Welding

- Friction Stir Welding

- Laser Welding

Surface & finishing

- Grinding & Polishing

- Powder Coating

- Anodizing

- Galvanizing

Electrical

- Connectors

- Wire-to-Wire Connectors

- Wire-to-Board Connectors

- Board-to-Board Connectors

- Terminal Blocks

- Automotive Sealed Connectors

Electrical Cable

- Shielded Power Cable

- Coaxial Cable

- Ribbon Cable

- High Voltage Cable

- EV Battery Cables

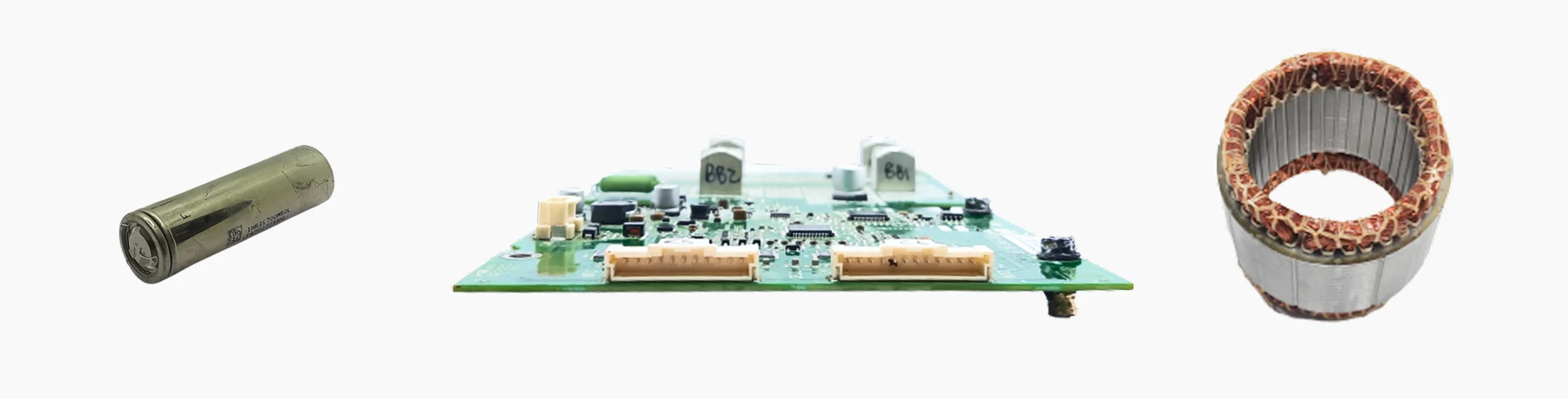

Cell

- Cylindrical Cell

- Prismatic Cell

- Pouch Cell

- LFP / NMC / NCA Chemistries

- Cell Terminal Configurations

Display

- LCD Panel

- LED Backlit Display

- OLED Display

- Touch Panel (Capacitive / Resistive)

- TFT Module

- PCB – Aluminium

- Single Layer Aluminium PCB

- IMS (Insulated Metal Substrate)

- High Thermal Conductivity Types

- LED Application Boards

PCB – Copper

- Heavy Copper PCB

- High Frequency PCB

- Multilayer Copper Core

- RF Power PCBs

PCB – FR4

- Standard FR4 PCB

- Multilayer FR4 PCB

- Rigid-Flex FR4

- High Tg FR4

PCB – Ceramic

- Alumina Ceramic PCB

- Aluminium Nitride PCB

- Direct Bonded Copper (DBC)

- Low-Temperature Co-fired Ceramic (LTCC)

- PCB – Flexible

- Single-Sided Flex PCB

- Double-Sided Flex PCB

- Rigid-Flex PCB

- Polyimide Substrate

Bare PCB – 1 Layer

- FR4 / CEM1

- HASL Finish

- Basic Copper Thickness

Bare PCB – 2 Layer

- FR4 / Aluminium

- Via Drilling

- ENIG / OSP Finishing

Bare PCB – 4 Layer

- Signal-Ground-Signal-Ground Stackup

- Controlled Impedance

- Via-in-pad Design

- Bare PCB – 6 Layer

- Power-Ground Separation

- High-Speed Signal Routing

- Blind & Buried Vias

Bare PCB – 8 Layer

- Advanced Multilayer Stackup

- High-Density Interconnect (HDI)

- Thermal Management Layers

Stator

- Laminated Core Stator

- Hairpin Wound Stator

- Slotted vs Slotless Stator

- Die Cast Winding

Rotor

- Squirrel Cage Rotor

- Interior Permanent Magnet (IPM)

- Surface PM Rotor

- Wound Rotor Construction

Machining

- Drilling

- Standard Twist Drilling

- Deep Hole Drilling

- Gun Drilling

- Pilot & Reaming

Tapping

- Hand Tapping

- Machine Tapping

- Blind Hole Tapping

- Thread Forming

Turning

- External Turning

- Facing on Lathe

- Grooving & Parting

- Thread Turning

Milling

- Face Milling

- Slot Milling

- Profile Milling

- End Milling

Threading

- Single-Point Thread Cutting

- Rolling Dies

- Thread Milling

- Facing

- Lathe Facing

- Plunge Facing

- Facing in Chuck Work

Broaching

- Internal Keyway Broaching

- External Surface Broaching

- Rotary Broaching

Grinding

- Surface Grinding

- Cylindrical Grinding

- Centerless Grinding

- Tool Grinding

Boring

- Line Boring

- Jig Boring

- Horizontal Boring

Notching

- Tube Notching

- Sheet Metal Corner Notching

- Angle Notching

- Laser Cutting

- Fiber Laser

- CO₂ Laser

- Pulse Laser for Microcutting

Honing

- Manual Honing

- Vertical Honing

- Plateau Honing (Automotive)

Gear Hobbing

- Spur Gear Hobbing

- Helical Gear Hobbing

- Spline Cutting via Hobbing

Gear Shaping

- Internal Gear Shaping

- External Gear Shaping

- Timing Gear Shaping

Gear Shaving

- Radial Infeed Shaving

- Diagonal Shaving

- Underpass Method

- Gear Grinding

- Profile Grinding

- Generating Grinding

- Form Grinding

Shot Blasting

- Steel Grit Blasting

- Wheel Blast Systems

- Shot Blast Cleaning

Shot Peening

- Air Blast Peening

- Gravity Peening

- Saturation Peening

Sand Blasting

- Suction Sandblasting

- Pressure Blasting

- Abrasive Media Selection

Lapping

- Flat Lapping

- Cylindrical Lapping

- Polishing and Final Finishing

Welding & Joining

- MIG / MAG Welding

- Carbon Steel MIG

- Stainless MAG

- Pulse MIG for Aluminum

TIG Welding

- Manual TIG

- Orbital TIG

- Thin Section Welding

- Spot Welding

- Projection Spot Welding

- Cross Wire Welding

- Resistance Spot Weld

Friction Stir Welding

- Aluminum Profile Joining

- Tool Steel Weld Head

- Automated Linear FSW

- Laser Welding

- Keyhole Welding

- Conduction Welding

- Fine Micro-Welds

Ultrasonic Welding

- Plastic Ultrasonic Welding

- Wire Splicing

- Battery Tab Welding

- Riveting / Clinching

- Solid Riveting

- Blind Riveting

- Mechanical Clinching

Surface Finishing

- Powder Coating

- Epoxy Powder Coat

- Polyester Powder Coat

- Hybrid Powder Finishes

Electroplating

- Nickel Electroplating

- Zinc Plating

- Chrome Plating

- Anodizing

- Type II Color Anodizing

- Type III Hard Anodizing

- Clear & Black Coatings

Galvanizing

- Hot-Dip Galvanizing

- Electrogalvanizing

- Dry Coating Post-Galv

- Passivation

- Citric Acid Passivation

- Nitric Acid Process

- Stainless Steel Surface Prep

- Deburring & Polishing

- Tumbler Finishing

- Vibratory Deburring

- Buffing & Brushing

Testing & Inspection

- Dimensional Inspection

- CMM Inspection

- Height Gauge / Vernier

- Go/No-Go Gauge

Visual Inspection

- Manual Surface Check

- Visual Defect Sorting

- Deflash / Burr Check

- X-Ray & CT

- Die-Cast Void Inspection

- Battery Cell CT Scan

- BGA Package X-Ray

- Hardness & Microstructure

- Rockwell / Vickers Testing

- Metallographic Etching

- Grain Size Analysis

- Leak & Pressure Testing

- Helium Leak Test

- Air Decay Test

- Hydrostatic Pressure Test

Packaging & Logistics

- Export Packaging

- Palletized Crates

- Heat-Treated Wood (ISPM 15)

- Heavy-Duty Shrink Wrap

Returnable Packaging

- Plastic Bin Systems

- Metal Returnable Cages

- Foldable Crates

- Thermoformed Trays

- Anti-Static Trays

- Custom Molded Cavities

- Conductive Tray Systems

- Labeling & Identification

- Barcode Printing

- Part ID & QR Labels

- Compliance Tagging (RoHS, REACH)

- Final Assembly Packing

- Subassembly Kits

- Cushioned Inserts

- Operator Instruction Leaflets

Miscellaneous

- Booklet

- Saddle Stitch Binding

- Perfect Binding

- Wiro Binding

- Folded Leaflet Assembly

- UV Coating & Lamination

Composite

- Prepreg Layup

- Vacuum Bagging

- Resin Transfer Moulding (RTM)

- Autoclave Curing

- Filament Winding

- Fabric – Rexine

- Heat Embossing

- Pattern Cutting

- Stitching & Overlocking

- Surface Coating

- PVC/PU Backing Lamination

Glass Sheet Manufacturing

- Float Glass Process

- Annealing & Cutting

- Coating & Tempering

- Silk Screen Printing

- Mirror Backing Application

- Glass Moulding

- Press & Blow Moulding

- Injection Blow Moulding

- Rotary Moulding

- Hot Mould Preheating

- Annealing Tunnel Furnace

Paper Packaging

- Corrugated Box Forming

- Die Cutting & Slotting

- Folding & Gluing

- Printed Sleeve Application

- Pulp Moulded Tray

- Substrate – Ceramic

- Alumina Ceramic Substrates

- Green Tape Lamination

- Laser Scribing

- Firing & Metallization

- Direct Bonded Copper (DBC)

Wood

- Plywood Cutting

- Edge Banding

- Laminate Pressing

- Routing & CNC Machining

- Surface Polishing

xcPROC.com – The Cost Data Hub

Vast Library of Built-In & Customizable Cost Databases

xcPROC® is the centralized database engine that powers every should-cost model in xcPEP.

Unlike traditional platforms that rely on third-party datasets and generic multipliers, xcPROC is built entirely by ASI’s data research team. Every value, whether it’s a machine-hour rate, RM price, operator wage, or tooling cost reflects real-world manufacturing conditions.

Currently housing nine specialized databases, xcPROC provides granular, context-aware inputs across domains like electronics, mechanical parts, operations, and raw materials. These datasets are continuously updated through field projects and deployment feedback.

When standard data isn’t sufficient, ASI’s Data Research Team can build fully custom cost databases or specific datasets within existing ones based on the user's requirements. These are then deployed in xcPROC and made available for use inside xcPEP cost models, ensuring every output reflects actual manufacturing conditions.

Most third-party data providers sell static libraries with outdated rates and generic assumptions xcPROC is different. It’s a continuously updated, deployment-backed infrastructure where every number is traceable to real manufacturing inputs, not spreadsheets or scraped catalogs.

Machine Database for Machine Hour Rate

The Machine Database contains structured cost parameters for manufacturing equipment across machining, forming, molding, and fabrication operations. Each machine entry includes brand, operation type, capital and rental costs, installation assumptions, and utility consumption. It also factors in productivity variables such as feed rate, uptime, and life, enabling precise calculation of the machine hour rate (MHR). This MHR serves as a foundational input in xcPEP for estimating operation-wise part costs and comparing routing options. The data is used in operation-level routing analysis within xcPEP and allows users to compare machine options across geography, process efficiency, and cost.

Wage & Salary Database for Labour Hour Rate

The Wage and Salary Database in xcPROC provides region-wise labour hour rates essential for calculating accurate manufacturing costs. It includes detailed breakdowns for skilled, semi-skilled, and unskilled labour, covering parameters such as minimum wages, allowances, perks, and total hourly rates. Categorized by industry and process type, this database helps ensure cost models reflect real workforce costs instead of assumptions. It plays a critical role in should-costing exercises, especially in labour-intensive operations like assembly, casting, and fabrication.

Raw Material Database for RM Rates

The Raw Material Database contains structured data for a wide range of materials used in manufacturing. Each entry includes material grade, sub-grade, initial shape, density, and cost per unit, along with the corresponding currency. This data allows cost models to reflect real-world sourcing conditions and material usage. It is primarily used in costing, alternate material evaluations, and benchmarking within xcPEP. All values are regularly updated to reflect region-specific sourcing and are maintained by ASI’s internal data research team.

Operations Database for different manufacturing process

The Operations Database in xcPROC stores cost and rate data for standard manufacturing processes such as machining, welding, coating, heat treatment, and forming. Each operation is linked to relevant parameters like process type, cost unit, and applicable materials or geometries. Unit rates are recorded in engineering-relevant formats such as INR per square meter or INR per kilogram, enabling seamless integration with routing logic in xcPEP. This database supports accurate process selection, supplier comparison, and plant-level cost simulation within should-cost models.![]()

Tools Database for tooling cost

The Tools Database in xcPROC captures tool-level information critical for operations such as assembly, machining, and forming. Each entry includes the tool’s specifications, supplier, material, and category—along with cost and usage life data. This enables tool depreciation to be factored into should-cost models where tooling is a cost driver. The database supports accurate evaluation of part-level tooling costs, especially in cases involving high-volume or custom tooling.

Custom Database for User-Specific Costing Needs

Not every cost model can rely on standard data. When users have requirements that fall outside predefined libraries, ASI’s Data Research Team creates custom databases—built from the ground up to reflect specific products, processes, or commercial needs.

This could include a packaging database tailored to export-grade assemblies, a costing structure for regional logistics, or datasets for highly specialized subcomponents. These databases are not extensions of existing ones—they are standalone, structured data sources created based on specific requirements of the user.

Once deployed in xcPROC, the data becomes available for use within xcPEP, ensuring that every model draws from inputs grounded in actual manufacturing conditions.

What Makes xcPEP Different

Features Designed for Structured, Transparent Should-Costing

Besides inbuilt models, during every xcPEP deployment, our ASI Engineering team studies customer's production portfolio.

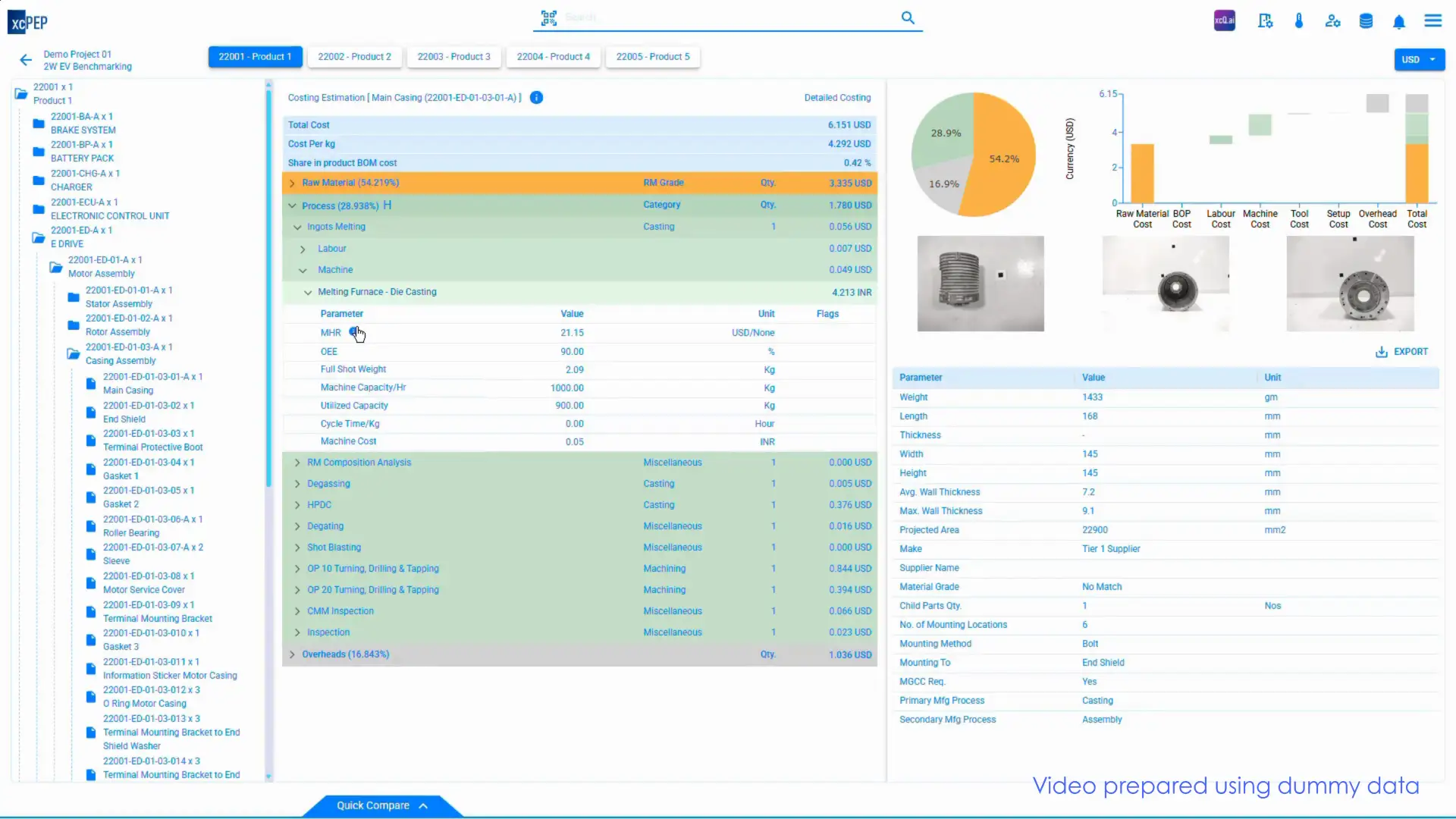

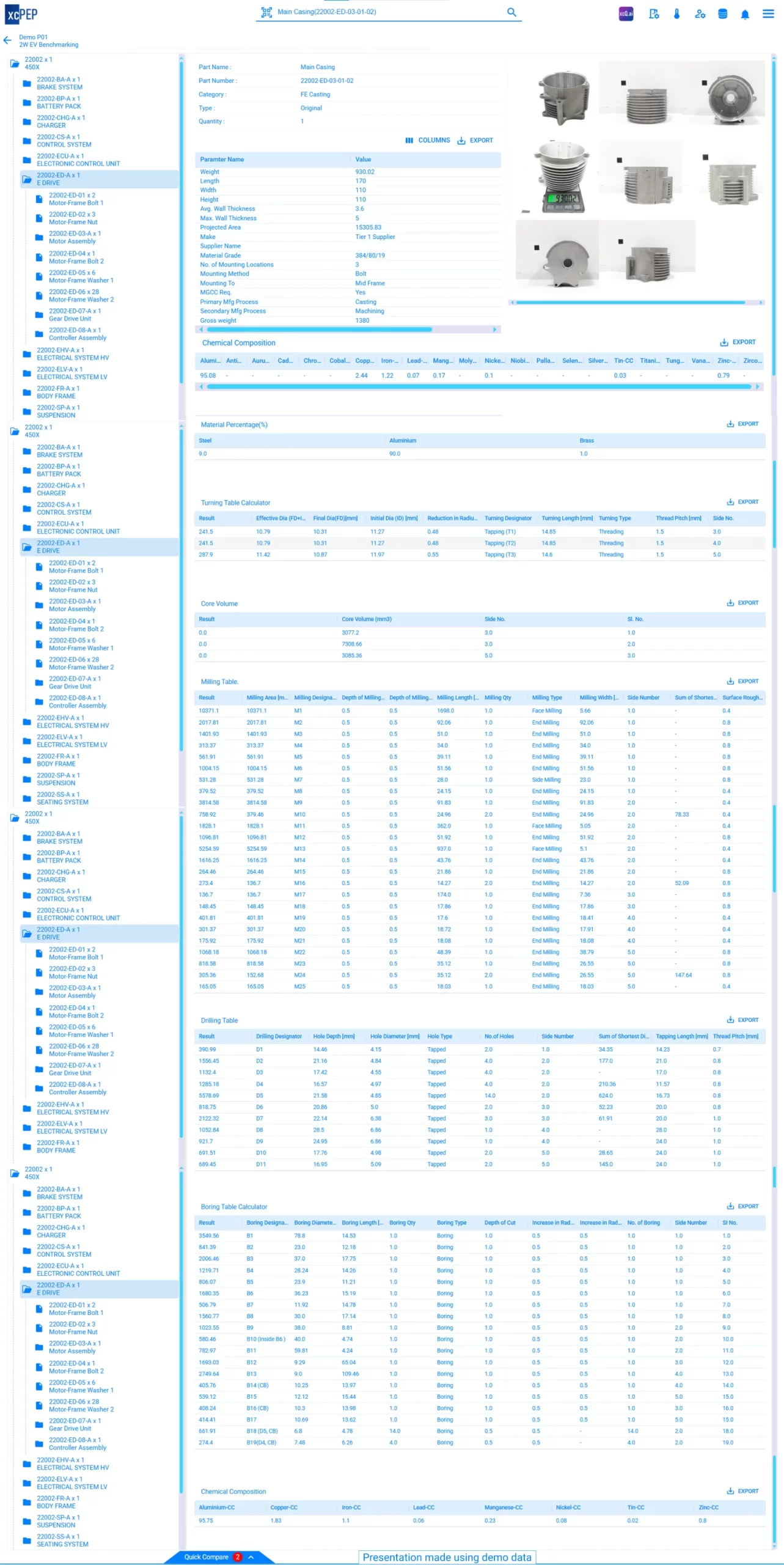

Detailed BOM and Part-Level Parameter Mapping

xcPEP enables detailed mapping of bill of materials (BOM) and part-level attributes using teardown studies & engineering drawings. For each part, more than 50 parameters are captured, including weight, geometry, box size, wall thickness, coating type, manufacturing category, material grade, surface area, and perimeter.

For mechanical components, data such as mounting methods, joining techniques, casting types, and machining details are also captured. For electrical components, the BOM includes semiconductor details, PCB attributes, number of layers, component placement, and manufacturer references. When drawings are available, parameters are extracted manually or via assisted parsing, enabling xcPEP to generate cost models directly from the data.

The BOM template is process-specific and fully editable. Users can modify it to add new parameters or build entirely new BOM templates as required. All mapped data is structured, traceable, and ready for use within the cost model engine.

Configurable Cost Models

xcPEP allows users to work with structured, editable cost models instead of static templates. Each cost model is built using equations and logic relevant to the specific manufacturing process being costed. Inputs such as material usage, cycle time, tool life, labour effort, and overhead allocation can be adjusted to match internal standards or supplier conditions.

Cost models in xcPEP are fully editable; users can modify them based on actual production flows. New Models can also be created from scratch for new processes, ensuring that cost logic remains relevant as products and technologies evolve. For specific requirements, additional parameters can be mapped into a model. For example, injection moulding models can be extended with user-defined fields beyond the defaults, allowing for deeper process-specific detail when needed.

Build-Your-Own Cost Models

For cases where standard cost models do not apply, xcPEP provides the ability to create fully custom models. Users can define process steps, assign formulas, and build part-specific costing structures from the ground up. Each model follows a consistent framework, allowing for integration with other platform modules. This flexibility ensures that niche processes, proprietary methods, or new product lines can be costed with the same level of control and consistency as standard components.

Input data required for these models, such as material prices, machine rates, or tooling norms, can be fetched from the xcPROC cost data service.

Built-in Cost Dashboards

xcPEP has in built dashboards that display cost breakdowns by part, process, material, supplier, and other filters. Users can view cost distribution as percentages or absolute values, enabling clear understanding of major cost drivers. No third-party BI tools are required; dashboards are built into the platform and update in real time as inputs or assumptions change. All data can be downloaded as Excel files for further analysis or sharing.

Scenario Simulation and Comparison

Users can create multiple scenarios for the same part or assembly by modifying key inputs such as production volume, material grade, process route, or supplier location. Each scenario is stored independently and can be compared using built-in tools. Graphical views allow users to see cost deltas and pinpoint which assumptions contributed to variation. This helps teams evaluate trade-offs before making sourcing or design decisions.

Cost Delta and Driver Analysis

When multiple scenarios or models are available, xcPEP highlights the changes in cost and identifies the key drivers. This helps teams understand how specific assumptions—like cycle time changes or material substitutions—impact final cost. The analysis is integrated into the comparison workflow, making it easy to trace outcomes back to decisions. It supports more informed discussions across engineering, sourcing, and finance.

xcPROC Cost Data Integration

xcPEP connects directly to xcPROC, ASI’s internal cost database. This allows users to access consistent values for raw material prices, machine-hour rates, labour costs, tooling norms, and more. All datasets are built and maintained by ASI and updated on a defined schedule. If a user needs data specific to a plant, region, or process, ASI can build and deliver that subset on request.

Users only subscribe to the datasets they need, and all data is formatted for direct use in xcPEP models. Since xcPROC is natively integrated with xcPEP, users do not need to depend on any third-party applications or external databases for costing inputs.

In Built Idea Tracker

xcPEP includes a dedicated module to capture cost-saving ideas generated during should-costing. Each entry records the proposal details, expected savings, source of the idea, and current status. Teams can use this feature to track progress, assign ownership, and quantify the impact of cost-reduction efforts. The module ensures that valuable insights from costing exercises are not lost and are tied to implementation.

Role-Based Access Control

xcPEP offers granular access control, allowing administrators to define who can view, create, or edit models and data. Permissions can be set at the module, part, or user level. This ensures that teams across engineering, sourcing, and finance have access only to the tools and data relevant to their work. The system supports parallel collaboration without compromising data integrity or control.

Multi-Team Collaboration

Multiple users from different functions can work on the same part or model simultaneously. Engineering teams can define the technical inputs, sourcing can simulate supply-side changes, and finance can view cost outputs—all within the same platform. Access is filtered by role, and activity is coordinated without overlap. This reduces delays and promotes transparency across functions.

Import Tools

xcPEP supports importing BOMs, technical specifications, and costing data from Excel, CSV, and XML formats. Part attributes and cost-related parameters can be bulk uploaded or mapped directly to model fields. This accelerates onboarding of new parts and supports integration with existing workflows. Import formats follow a consistent structure to maintain model integrity.

Custom Reporting and Downloadable Output

All outputs in xcPEP—including full cost breakdowns, comparison reports, and part summaries—can be downloaded in structured Excel formats. Reports are formatted for clarity and ready to be used in internal reviews, supplier discussions, or audits. This enables seamless communication between teams and across functions, while keeping a clear record of cost decisions.

API-Based Integration

The platform provides APIs for integration with external systems such as PLM, ERP, or reporting tools. Data can be exchanged bi-directionally, allowing updates to BOMs, supplier lists, or cost outputs to flow seamlessly between systems. Integration helps avoid duplication of effort and improves alignment with broader digital infrastructure.

Advanced Data Capture Hardware

Developed by ASI to accelerate teardown and costing workflows.

ASI has developed custom hardware systems to accelerate and standardize data capture during teardown. These tools integrate directly with xcPEP and enable fast extraction of both physical and electronic parameters with minimal manual input. By digitizing key steps such as PCB component identification, bounding box measurement, and projected area capture, the hardware reduces lead times and ensures consistent, reviewable inputs for cost model generation. This setup is built to support high volume costing programs where speed, repeatability, and data reliability are critical.

AI-Based PCB Component Identification

In electronics should-costing, one of the most critical and time-consuming tasks is accurately identifying every component mounted on a PCB. Manual identification is slow, error-prone, and difficult to scale—especially across complex assemblies and large teardown programs.

To address this, ASI uses a calibrated imaging setup to capture high-resolution images of each PCB, which are then processed in xcPEP. The platform automatically detects and classifies all mounted components—such as ICs, resistors, capacitors, transistors, and diodes—without any manual tagging. Each part is then matched against the xcPROC database to populate fields such as item name, description, quantity, manufacturer, and MPN. The resulting BoM table is displayed within the part page for review and downstream cost modeling.

Bounding Box Dimension Capture System

In mechanical should-costing, bounding-box dimensions—length, width, and height—are foundational inputs. They drive extrusion cost, raw material planning, packaging volume, and transport layout. When captured manually using calipers or tapes, these measurements can be slow, error-prone, and difficult to standardize across large teardown batches—especially for irregular or bulky parts.

To streamline this step, ASI uses a laser-based setup that captures all three dimensions without physical contact. The part is placed in a calibrated enclosure, and laser modules are aligned to its outer edges. The system calculates real-world bounding-box dimensions using reference positions and transfers them directly to xcPEP.

These values are used across multiple cost models—supporting extrusion costing, blank size estimation, packaging design, and logistics planning—ensuring dimensional accuracy at the very first stage of cost model creation.

Automated Projected Area Capture System

Projected area is a key parameter in the cost models used for plastic and sheet metal parts. In injection moulding, it determines the tonnage required by the moulding machine, directly impacting equipment selection, tooling cost, and cycle time. In sheet processes, it influences blank sizing, nesting layout, and surface operations like painting or coating.

When measured manually by placing the part on a grid and estimating coverage, the process becomes slow, error-prone, and difficult to scale. At higher volumes, this leads to inconsistent input data that affects the reliability of downstream cost models.

ASI captures projected area by placing the part against a calibrated reference grid. The system detects the outer contour, filters background noise, and calculates the 2D area in real-world units. The result is recorded in the BoM and used across cost models wherever area-based logic applies.

Click here to watch this video on YouTube. Rejecting cookies can sometimes cause loading issues.

Use cases of xcPEP

Used by OEMs, Tier-1s, and Product Teams from design reviews to cost-down programs

xcPEP is deployed across industries and functions wherever teams need to make cost decisions that hold up to review. It’s used during early design to evaluate concepts, during sourcing to validate quotes and benchmark alternatives, and after launch to drive structured cost reduction. The platform adapts to different workflows: in some cases, it powers full-fledged cost labs; in others, it’s used for focused projects like teardown benchmarking, make-vs-buy analysis, or scenario-based forecasting. What connects them all is the need for transparent, logic backed should costing built on real data.

Below are some of the most common use cases we’ve seen.

Cost Lab Setup

xcPEP was deployed to establish an in-house cost lab for structured, repeatable should-costing, following a Build–Operate–Transfer model. ASI’s engineering team began by configuring the platform to match the company’s internal BOM formats, product hierarchy, and data standards. Key cost models were created for priority components, and xcPROC was integrated to provide region-specific rates for materials, machines, and labour.

Initial projects were executed jointly in a build-operate-transfer mode—where ASI engineers handled the costing and simultaneously trained the customer’s team. As users gained confidence, the responsibility transitioned fully. Today, the organization runs its own cost lab on xcPEP, with ASI providing database updates and technical support as needed.

Should-Costing for New Part Development

xcPEP was deployed to generate structured cost estimates during early part development—before supplier quotes were received. Engineering and sourcing teams used the platform to build initial cost models directly from part drawings or BOMs, defining parameters such as material, geometry, tolerances, and manufacturing process.

Costing assumptions were configured using data from xcPROC, including machine rates, labour inputs, raw material prices, and tooling estimates—adjusted for the intended sourcing region. Models were refined as design iterations progressed, allowing early cost targets to be set and validated before RFQ.

This helped teams enter the sourcing process with a clear cost reference, reduce dependency on external benchmarks, and catch high-cost design decisions early in the development cycle.

Fact Packs for Supplier Negotiations

xcPEP was deployed to generate internal cost references that could be used during supplier negotiations. Teams built part level cost models using drawing data, process logic, and sourcing region rates from xcPROC. These models provided a clear, defensible breakdown of expected part cost, including raw materials, machine operations, and overheads.

The should cost outputs were then used to prepare fact packs for supplier discussions, giving sourcing teams a structured reference point to validate quotes, question outliers, and negotiate with greater clarity. The ability to simulate routing changes or volume shifts in real time made xcPEP a valuable tool during pre RFQ planning and post quote review.

Competitor Cost Benchmarking

xcPEP was deployed to perform should-cost analysis of a competitor’s product to evaluate cost structure and sourcing decisions. Teardown data was used to build part-level cost models, with materials, processes, and joining methods mapped using xcPEP’s parameter-based structure. Each manufacturing step was costed using data from xcPROC, including region-specific rates for machines, labour, and raw materials.

This enabled a line-by-line cost breakdown of the competitor’s product, which was benchmarked against internal estimates. Differences in design approach, process selection, and location-based costs were analysed using xcPEP’s scenario tools. The output provided a clear basis for identifying cost gaps and evaluating alternatives.

Cost Reduction Function Digitization

xcPEP was deployed to digitize and manage the organization’s cost reduction efforts across teams and programs. Previously scattered across spreadsheets and email threads, cost-saving ideas were moved into a centralized system using xcPEP’s Idea Tracker module. Each idea was tagged to a specific part or assembly, along with projected savings, implementation status, and responsible team.

Users could simulate changes directly within the platform—modifying geometry, material, or process routing to evaluate the actual cost impact using xcPROC data. Approved ideas were versioned into the main cost models, making every change traceable from proposal to implementation.

By bringing cost reduction activities into xcPEP, the organization gained visibility into pipeline health, avoided duplication, and ensured that cost-saving efforts could be tracked, validated, and revisited at any time.

Scenario Costing & Analysis

xcPEP was deployed to evaluate how design decisions and cost inputs affect part-level pricing. During product development, teams used the platform to simulate changes in tolerance, feature complexity, or process selection—and review how each variation impacted cost. The same approach was used to test external factors like raw material price changes, exchange rate shifts, or updated labour rates. Cost models were duplicated, adjusted with data from xcPROC, and compared against the original baseline. This helped teams make early design trade-offs, prepare for supplier discussions, and build cost forecasts—all while keeping every version traceable and assumption-driven.

xcPEP vs Traditional Costing Tools

What sets xcPEP apart from spreadsheets and legacy parametric costing tools?

While traditional tools like Excel and parametric costing tools are commonly used for estimation, they fall short in real-world should-costing. Parametric costing tools rely heavily on design-time inputs and CAD assumptions, making them less effective in teardown or benchmarking scenarios where real part data matters most. Excel provides flexibility but becomes unmanageable at scale, lacking traceability, version control, and standardization.

xcPEP bridges these gaps with a platform purpose-built for should-costing teams, especially those working with teardown-derived inputs, actual components, and manufacturing realities. It combines structure, transparency, and part-level traceability to ensure that every model reflects defendable assumptions and produces actionable, engineering-grade cost insights.

Features

xcPEP

Legacy Parametric Costing Tool

Excel

Real world process accuracy

Automated approximate cost from CAD

Precise costing from manufacturing drawings or physical parts

Detailed costing of electrical and electronics parts

Custom and realistic RM, LHR, MHR & other inputs

High speed performance in cloud

Cost models match actual vendor base & norms

Built for purchase & negotiation

Low cost of ownership

Ease of use

Integration with ERP, PLM & any other system

Support from cost engineers working on actual costing projects

Entire organization's direct purchase costing, RM indexing and digital operation.

Why Automated Costing Alone Falls Short

The fundamental weakness of legacy costing software

In today’s global manufacturing environment, cost estimation is more complex than ever. Automated costing software promises speed and scale by analyzing 3D files or applying generic rules to derive manufacturing costs. Yet, this “one-size-fits-all” automation often fails to deliver accurate results. Why? Because real-world manufacturing processes vary widely depending on region, industry, manufacturer capabilities, quality standards, raw material availability, and supplier networks.

The Pitfalls of Pure Automation in Costing

Automated costing engines that rely exclusively on CAD or preset formulas often gloss over these nuances, resulting in “black box” outputs that lack transparency and real-world accuracy. Companies using such models may find themselves negotiating or planning based on faulty data, impacting profitability and supplier relationships.

- A machining process in Germany with strict quality norms, high labor costs, and premium materials differs vastly from one in Southeast Asia.

- Electrical component sourcing and assembly methods vary from one industry vertical to another, depending on technology maturity and supplier base.

- Raw material availability can modify manufacturing processes across the world for achieving the same outcome.

5% error in cost calculation leads to 50% error on EBIDTA level.

The Power of xcPEP’s Templatization Approach

xcPEP’s Solution: Collaborative Templatization for Real-World Accuracy

At Advanced Structures India (ASI), we believe the answer lies in blending automation with collaborative customization. Instead of solely depending on automated algorithms, xcPEP’s approach focuses on working closely with each customer to build customer-specific cost templates.

Deep Customer Collaboration

Development of Templatized Cost Models

Reusable, Extensible Templates

Transparent, Traceable Costing

Benefits of Templatization-Enabled Automation

- Higher Accuracy: Cost estimates mirror your specific manufacturing environment and supply chain realities.

- Flexibility and Control: Easily adapt templates as suppliers change, materials fluctuate, or production methods evolve.

- Speed and Scalability: Once tailored, costing becomes a rapid exercise scalable across teams and part families.

- Better Negotiation Power: Transparent, defendable cost breakdowns lead to more effective supplier discussions.

Frequently Asked Questions

What teams usually ask when evaluating xcPEP.

Most costing tools restrict users to fixed templates, generic assumptions, or early-stage CAD inputs that break down when applied to real-world programs. xcPEP takes a different route: editable models, teardown-ready inputs, plant-level logic, and team-wise access control. From procurement heads to engineers to cost controllers, here are the questions we most often get when companies are evaluating xcPEP for serious should-costing work.

Does xcPEP require CAD models to create cost models?

No. Cost models can be built from 2d drawings, physical parts or teardown data. CAD models are not mandatory.

Can we build our own costing logic inside xcPEP?

Yes. Every step of the model—operations, formulas, parameters—is fully editable. You can replicate plant-specific routings or supplier-side processes without being locked into templates.

Can xcPEP be deployed internally, or is it only used through ASI projects?

Both. Many organizations run their own cost labs using xcPEP. Others engage ASI to execute projects using the platform, especially when bandwidth is limited. The software supports both self-use and service-driven models.

How do you bill for xcPEP?

xcPEP is billed as annual subscription only. Multi year fixed price contracts can be made. Support costs are built into the subscription price.