Off Highway

Our core SaaS platforms, xcPEP and xcPROC, are purpose-built to tackle the unique cost challenges of off-highway vehicle manufacturers : low volumes, high customization, and a heavy reliance on sourced components.

Backed by our in house services team - ASI Engineering, one of the few dedicated cost engineering teams in the world, we provide support to ensure successful adoption, data quality, and continuous cost reduction across complex, low-volume programs.

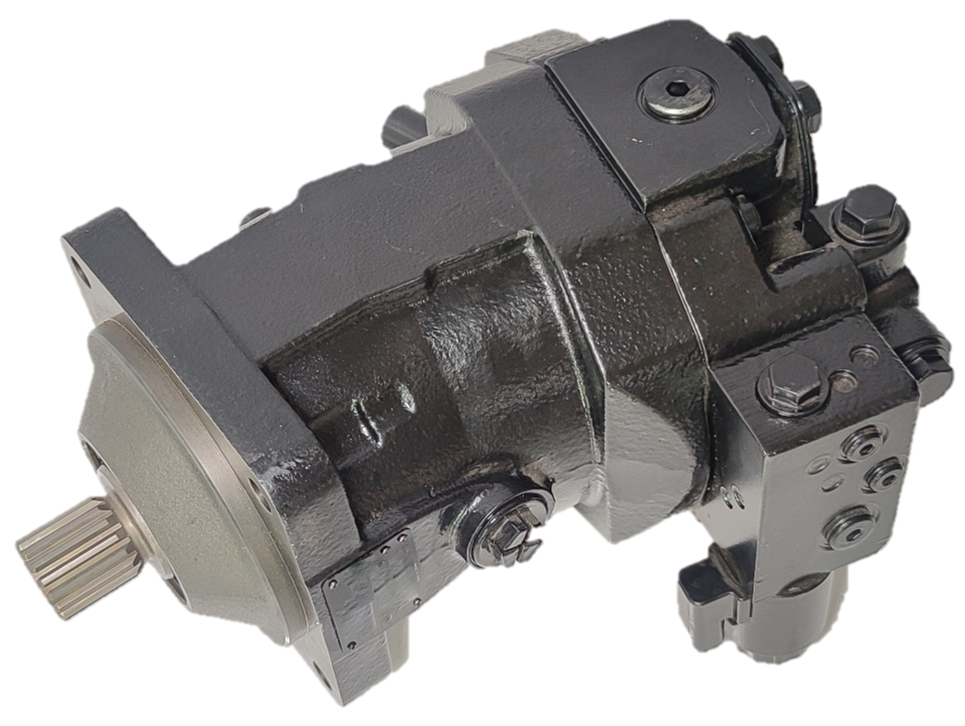

For over 5 years, we have been working regularly with off‑highway OEMs addressing lower production volumes, a high mix of purchased or proprietary parts, complex castings and forgings, hydraulic systems, stringent durability requirements, rugged operating environments, and long product lifecycles.

Machines

Geographies

And more data points

Below are turnkey services where we partner with off‑highway OEMs on a project basis. All offerings are delivered through xcPEP and xcPROC.

Should Costing

We use engineering drawings or teardowns to deliver precise should-cost estimates for castings, hydraulics, weldments, and systems.

Cost Reduction Studies

We benchmark your machine with your competitors to uncover cost-saving opportunities in materials, processes, labour & supply chain.

xcPEP Deployment

We tailor xcPEP to your products, suppliers, locations, and build custom raw material, MHR, and LHR datasets.

Cost Lab Build-Operate-Transfer

We set up a cost lab, create SOPs, train your team on live projects, and deliver a fully functional setup.

Deployment and Cost Lab Build-Operate-Transfer are services through which the ASI Engineering team ensures xcPEP is properly configured and effectively utilized.

How are we different?

We build cost engineering technology. Our core products, xcPEP for should cost modelling and xcPROC for cost data, form a powerful ecosystem supported by engineering services that speed customer adoption. While we may resemble consulting or benchmarking firms, the similarity is only superficial; our strength lies in the technology we create.

|

ASI vs. Management Consultants vs. Benchmarking Companies

Approaches to Cost Optimization for Off-Highway Equipment Manufacturers

|

||

| ASI – Engineering-Led Cost Transformation | Management Consultants | Benchmarking Companies |

|---|---|---|

| Engineering-led cost transformation using xcPEP & xcPROC, tailored for tractors, construction, and agricultural equipment. Focus on sustainable, structural cost reduction across full product lifecycles. | Strategy-focused consulting aimed at solving isolated problems. Engagements are billable-hour driven and often lead to recurring cost challenges. | No pre-existing off-highway equipment database. Deliverables based on expensive, one-off teardown or reverse-engineering projects. |

| Transparent Should Costing for every part, adapted to each manufacturer’s supply base and production process. Highly detailed, data-driven simulations enabling targeted cost-reduction initiatives. | Relies on SME expertise and generic industry data. Often produces incremental changes without addressing systemic cost drivers. | Costing often based on simplistic formulae from limited teardown samples. Insights rarely capture the complexity of heavy-duty off-highway components. |

Proprietary platforms:

|

General financial models and operational frameworks. Lacks manufacturing-specific cost simulation capabilities. | Uses ad-hoc analysis tools for each engagement. No scalable platform for repeatable, accurate cost estimation. |

| Measurable, sustainable cost reductions with direct impact on margin and competitiveness. | Recommendations improve current state but may not deliver optimal or lasting results. | Outcomes are slow, costly, and often fail to justify the investment. |

| Rapid portfolio-wide analysis with live costing tools – weeks, not months. | Multi-month projects from start to final report. | Slow, custom project timelines with long lead times for any usable insights. |

Our Core Objective

|

Engineering Led Cost Transformation

Of Off-Highway OEMs and Tier 1 Suppliers

|

||

| Challenge | ASI Solution | Value |

|---|---|---|

Key Challenges

|

Our Framework

|

Business Impact

|

| Core Technology Platforms | ||

|

xcPROC Procurement Intelligence

|

xcPEP Costing Engine Precise Should Costing

|

xcPEP Idea Module Automated Design & Commercial Idea Generation

|

| Build - Operate - Transfer Engagement Model | ||

|

Phase 1: Build Detailed Should-Costing Foundation

|

Phase 2: Operate Idea Generation & Implementation

|

Phase 3: Transfer Cost Engineering Function Handover

|

|

|

|

| Deliverables & Outcomes | ||

Immediate

|

Medium-Term

|

Long-Term

|

Product Studies

Our engineers regularly undertake internal projects on products of interest. These initiatives help enhance our solutions for specific product categories and also generate demo data for customers to evaluate. Below are blogs showcasing the outcomes of these studies.